®

U

P

C

W11572554A

Certied by

International Association of Plumbing and Mechanical Ocials (IAPMO) R&T

NSF/ANSI 42, 44, 61 & 372 · IPC · IRC

Reference Performance Data Sheet

WATER TREATMENT SYSTEM

OPERATION MANUAL

ST SERIES

2

TABLE OF CONTENTS

WATER TREATMENT SYSTEM SAFETY ...................................................................................................... 3

INTRODUCTION .............................................................................................................................................. 4

Main Parts .......................................................................................................................................................... 4

INSPECTION .................................................................................................................................................... 5

Valve Layout ....................................................................................................................................................... 6

Mineral Tank ....................................................................................................................................................... 6

PARTS AND FEATURES ................................................................................................................................. 6

Control Layout .................................................................................................................................................... 6

Brine Tank ........................................................................................................................................................... 6

EQUIPMENT DIMENSIONS ............................................................................................................................ 7

SYSTEM LAYOUT ............................................................................................................................................ 8

SYSTEM SPECIFICATIONS ........................................................................................................................... 9

Location Requirements..................................................................................................................................... 10

INSTALLATION INSTRUCTIONS ................................................................................................................. 10

Electrical Requirements.................................................................................................................................... 10

Mechanical Requirements .................................................................................................................................11

General Requirements ......................................................................................................................................11

EQUIPMENT INSTALLATION ....................................................................................................................... 11

Bypass Valve Operation ................................................................................................................................... 12

Brine Line and Safety Brine Valve ................................................................................................................... 13

Connections...................................................................................................................................................... 13

Safety Brine Valve Assembly ........................................................................................................................... 13

................................................................................................................ 14

Media Volume, Salt and Capacity Settings....................................................................................................... 15

Cycles and Softening Set Up............................................................................................................................ 15

SYSTEM OPERATION ................................................................................................................................... 17

Cycle Sequence ............................................................................................................................................... 19

Softener System Setup..................................................................................................................................... 20

User Display Settings ....................................................................................................................................... 25

Diagnostics ....................................................................................................................................................... 27

Valve History ..................................................................................................................................................... 29

PLACING WATER SYSTEM INTO OPERATION ........................................................................................ 31

................................................................................................................ 35

DRAWINGS AND PART NUMBERS ............................................................................................................. 35

Control Valve - Front Cover and Drive Assembly ............................................................................................. 36

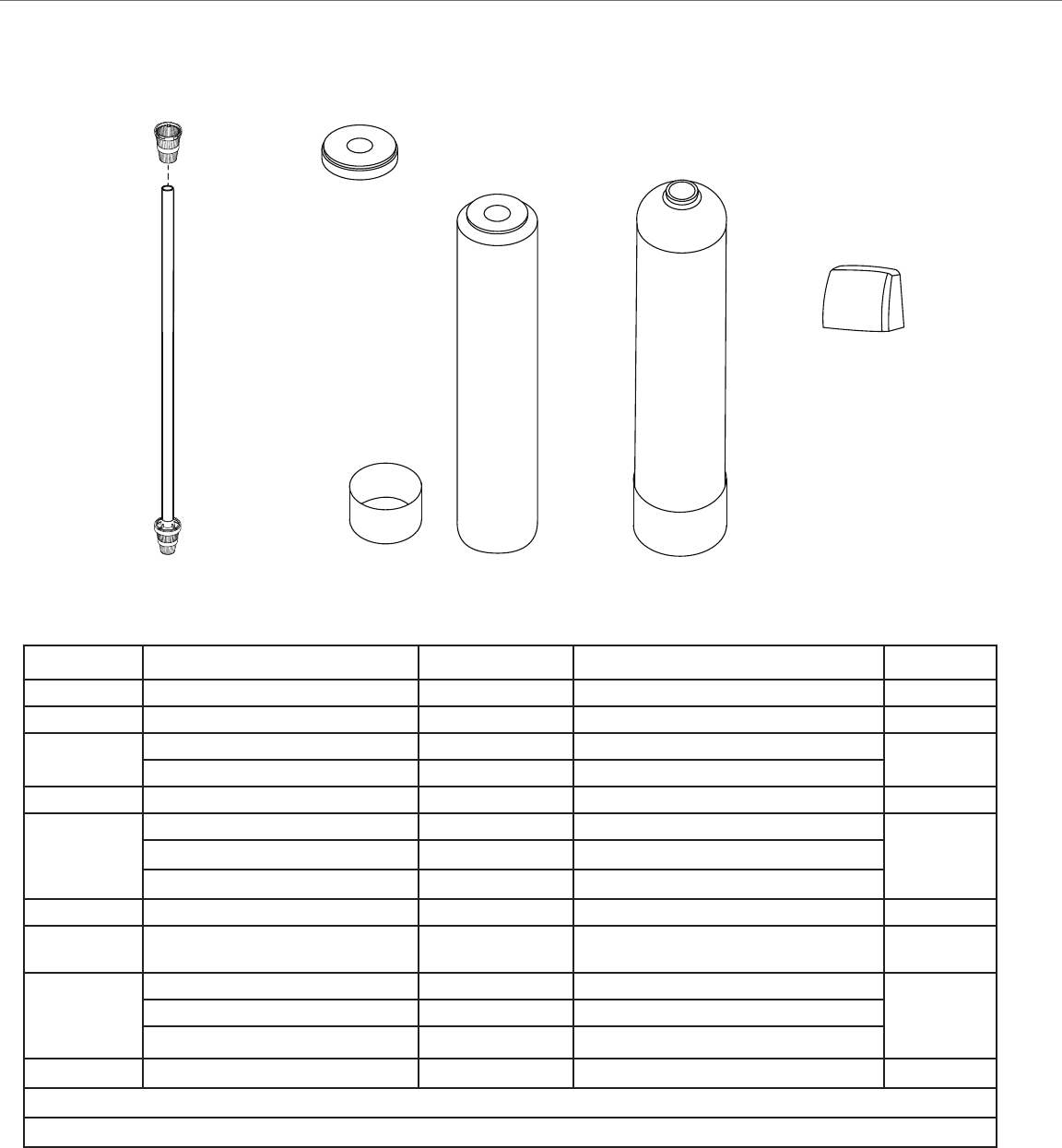

Brine Tank Assembly and Parts List ................................................................................................................. 37

Mineral Tank Assembly, Valve Cover, and Parts List ........................................................................................ 38

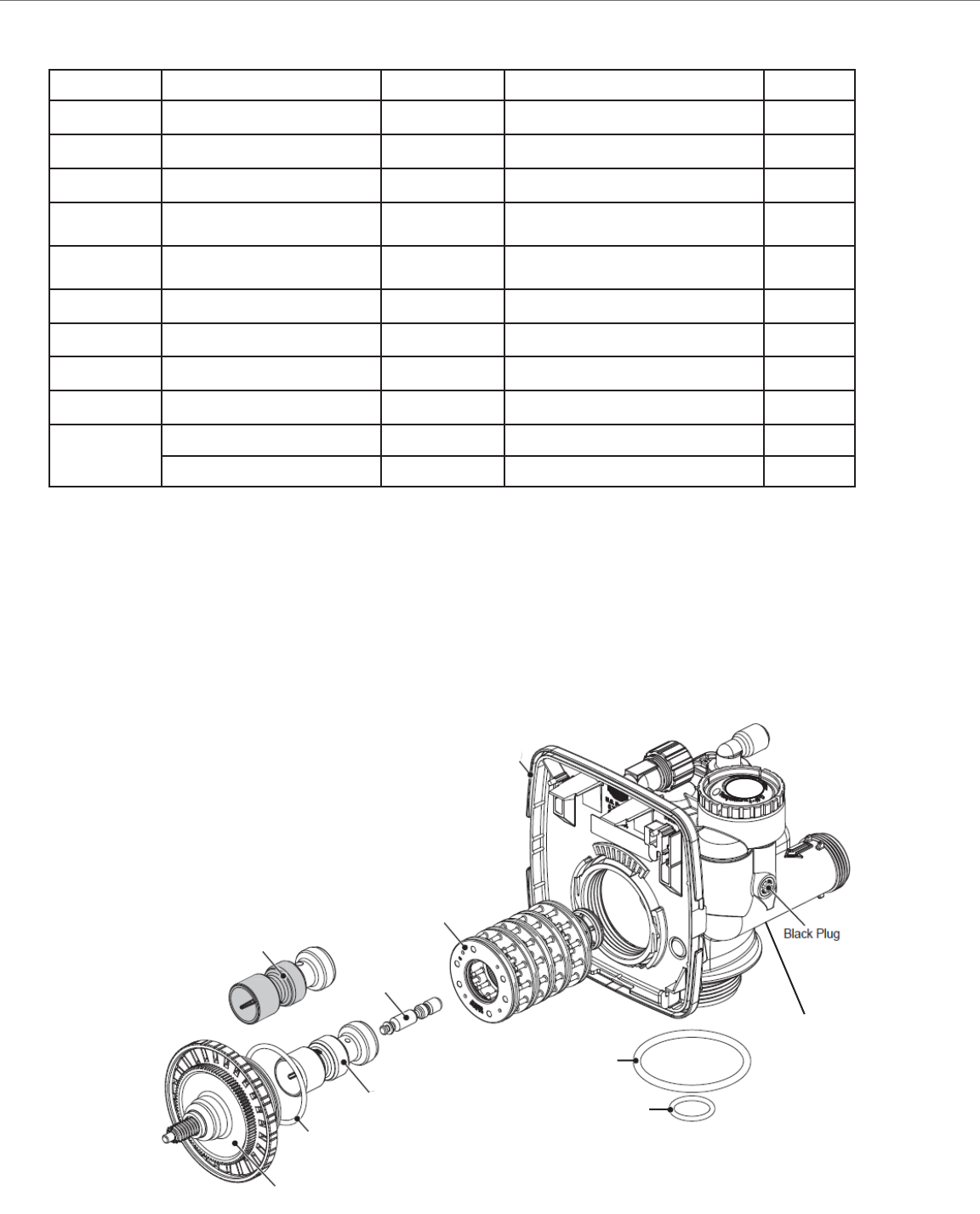

Control Valve - Drive Cap, Piston, Regenerant Piston, and Stacker Assembly ................................................ 39

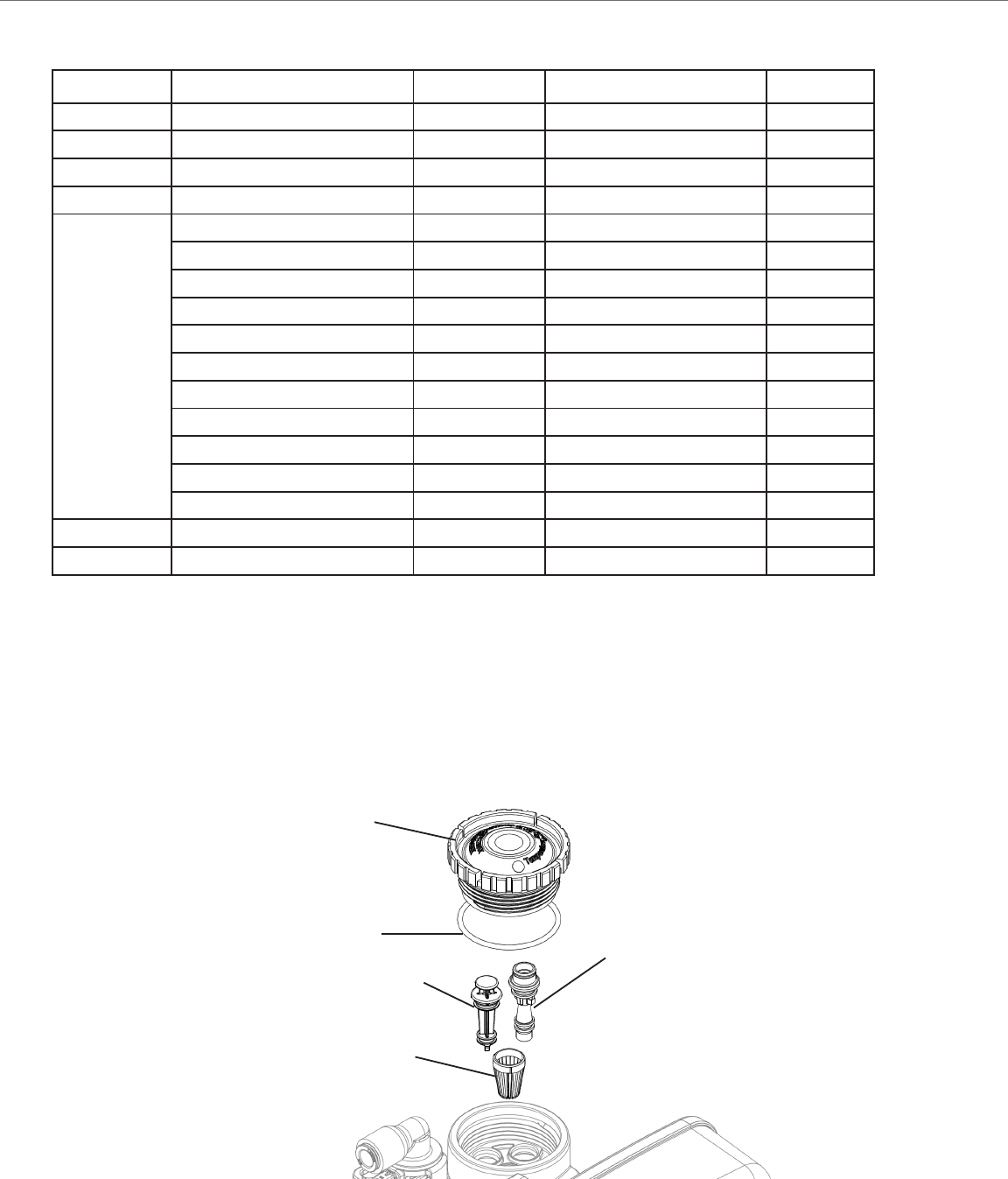

Control Valve - Injector Cap and Injector ......................................................................................................... 40

............................................................................................ 41

.................................................................................................................... 42

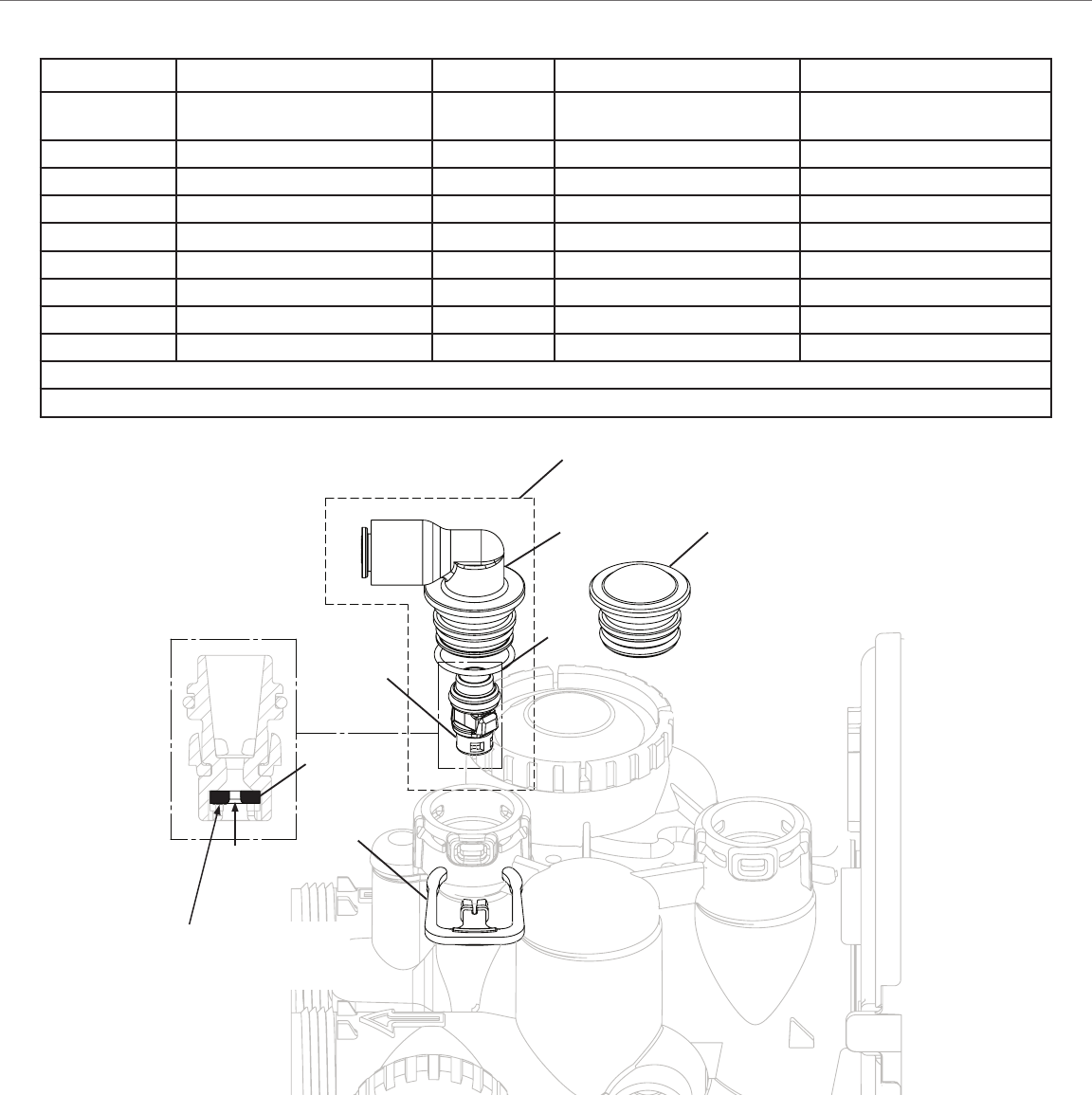

Water Meter, Meter Plug, and Mixing Valve...................................................................................................... 43

Bypass Valve .................................................................................................................................................... 44

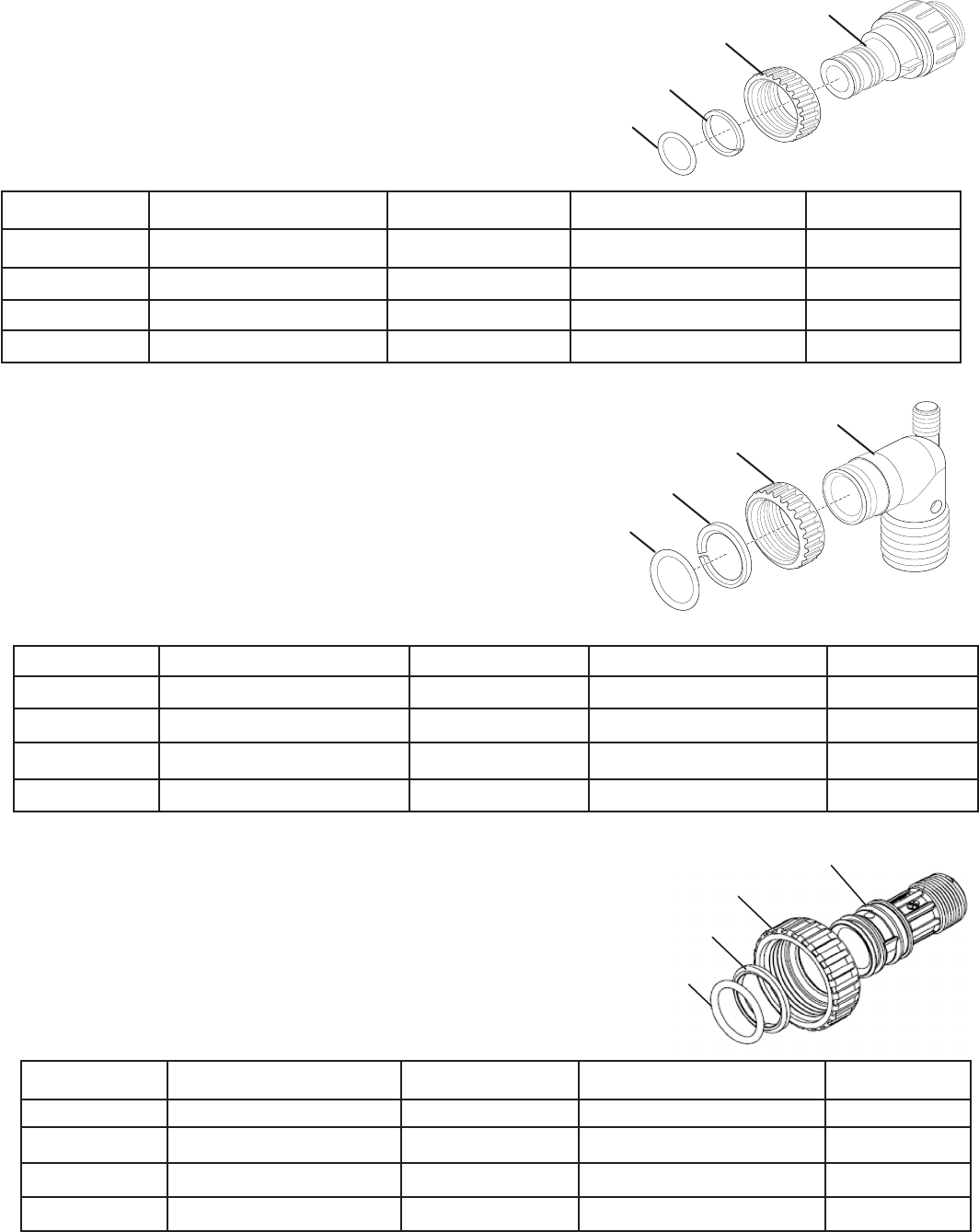

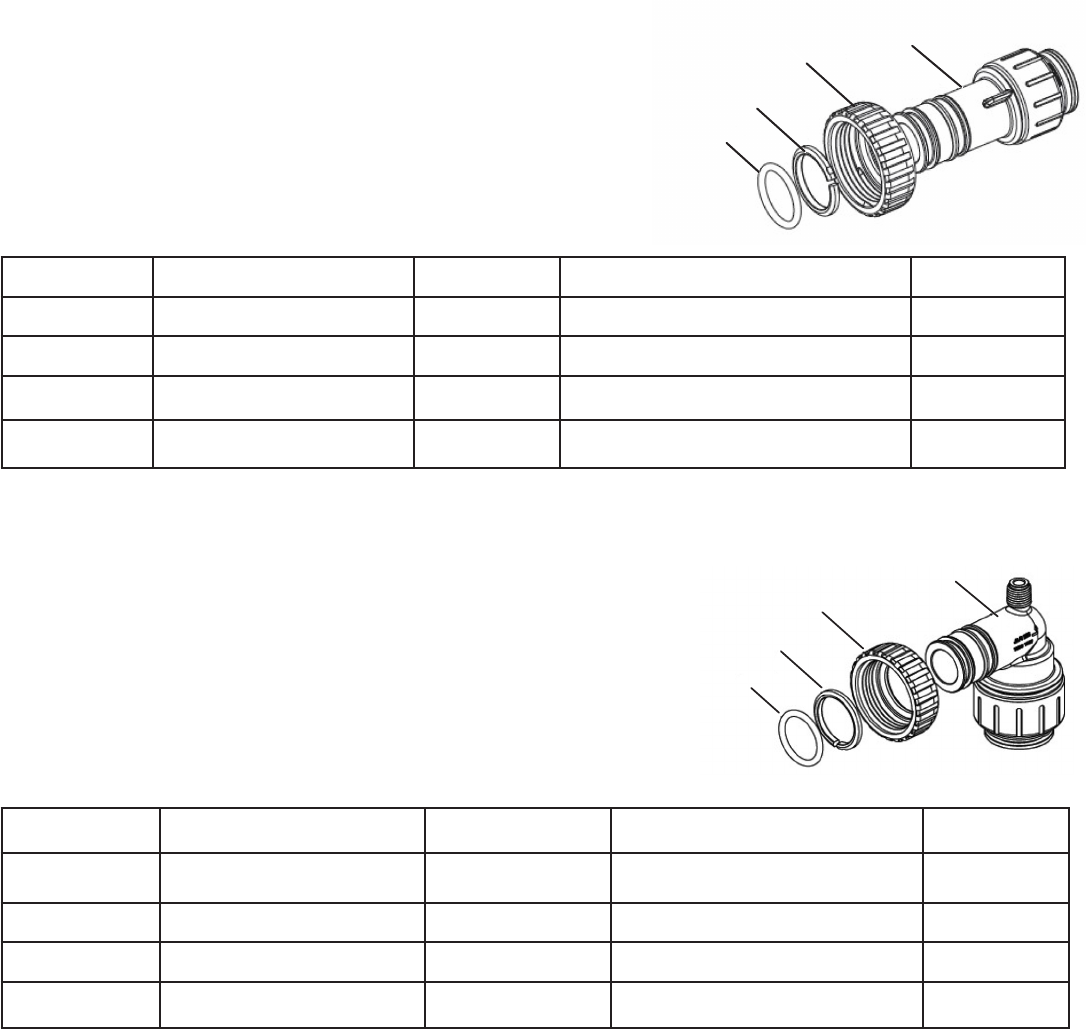

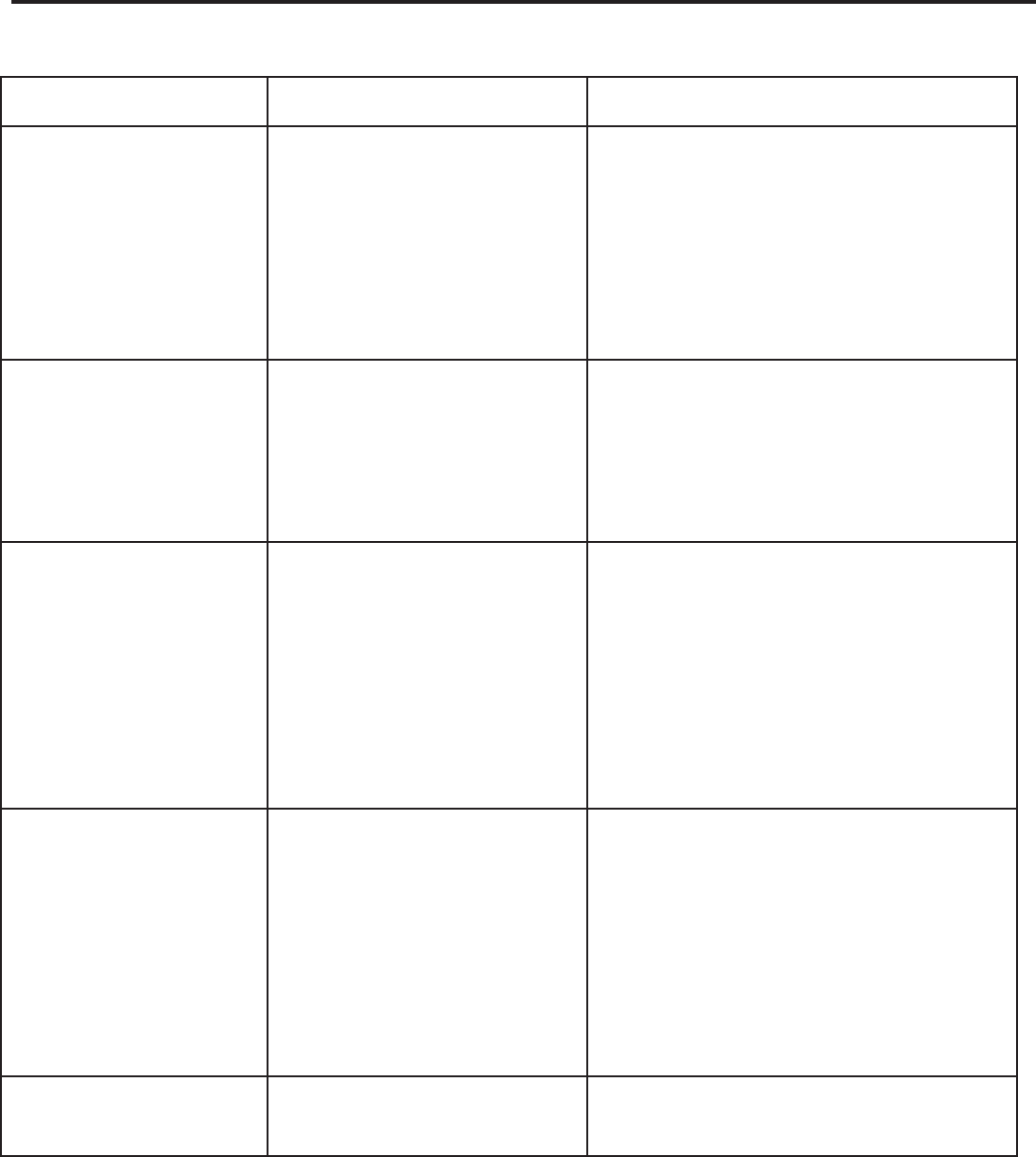

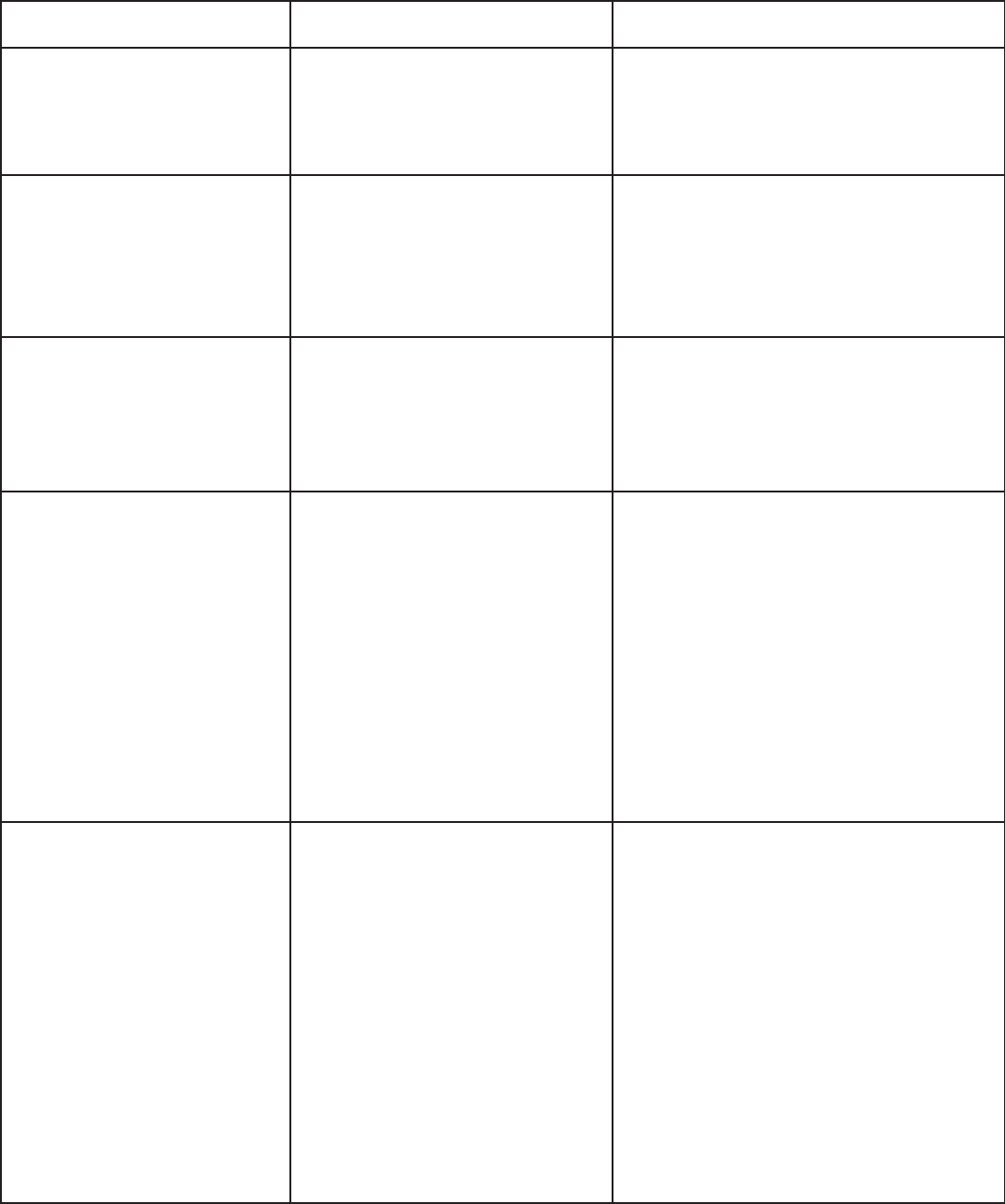

Bypass Fitting Packages .................................................................................................................................. 45

BYPASS FITTING PACKAGES .................................................................................................................... 45

Bypass Fitting Packages .................................................................................................................................. 46

Bypass Fitting Packages .................................................................................................................................. 47

Bypass Fitting Packages .................................................................................................................................. 48

Bypass Fitting Packages .................................................................................................................................. 49

TROUBLESHOOTING ................................................................................................................................... 50

PERFORMANCE DATA SHEET ................................................................................................................... 56

PERFORMANCE DATA SHEET ................................................................................................................... 57

Warranty ........................................................................................................................................................... 58

Notes ................................................................................................................................................................ 59

3

You can be killed or seriously injured if you don't

immediately follow instructions.

You can be killed or seriously injured if you don't

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and

tell you what can happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

DANGER

WARNING

WATER TREATMENT SYSTEM SAFETY

4

IMPORTANT:

result in personal injury or damage to the equipment.

This purpose of this installation manual is to guide the

installer through the installation and operation process of

MAYTAG

®

This manual is a reference and not included in every

system installation situation. The technician installing this

equipment must have:

Training in the MAYTAG

®

series controllers.

proper control settings.

Basic plumbing skills.

The directional instructions “left” and “right” are

determined by looking at the front of unit.

Inspect the unit for damage or missing parts.

Contact your supplier if any discrepancies exist.

Brine Well Assembly

Water Bypass

Plumbing Connectors

Left

Right

INTRODUCTION

Outlet

Main Parts

Inlet

Figure 1: Typical Inlet/Outlet Piping and

Valves for Proper Startup and Servicing

Outlet

Treated

Water

Supply

Inlet

Untreated

Water

Supply

5

Remove system from carton:

1. Remove the box top from the system.

2.

3.

4. Remove the components from the shipping carton (bypass box, brine tube assembly, plumbing

connectors & brine tubing)

5.

To assemble the Salt Tank:

1.

One to a drain and one to the valve.

2.

3.

4.

holes in the side of the brine tank.

5.

IMPORTANT:

back quickly, the particles may enter the valve. If this happens, the valve may need to be disassembled and

cleaned.

1. Stand the tank up and in position.

2.

Figure 2

INSPECTION

inspected for damage.

If any parts are damaged or missing, contact your supplier.

IMPORTANT:

6

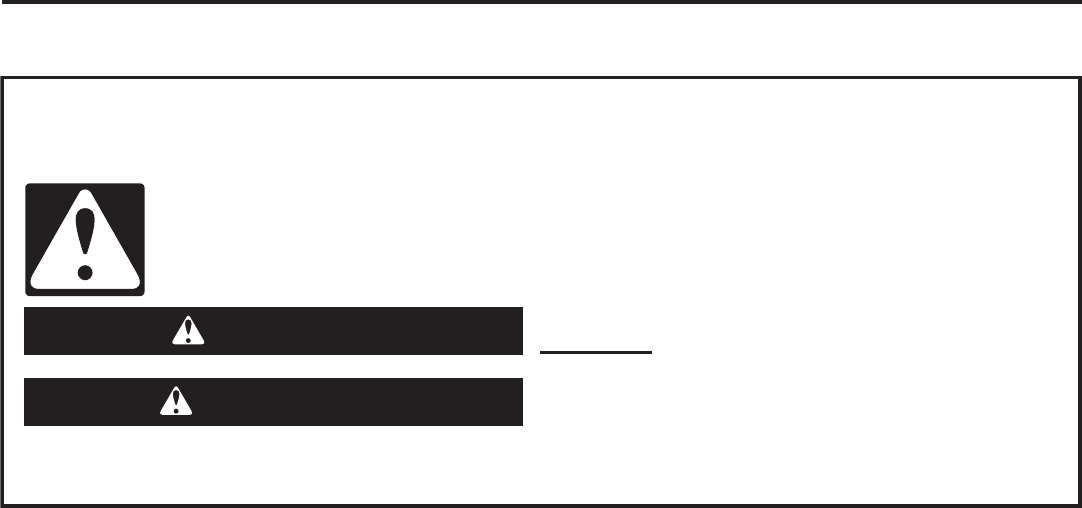

1. Tank Jacket Cover 5. Mineral Tank

2. Tank Jacket Sleeve 6. Upper Basket

3. Tank Jacket 7. Distributor Asy

4. Valve

1. Rell Flow Control Fitting 3. Untreated Water Inlet

2. Drain Fitting 4. Treated Water Outlet

1

3

1

2

3

4

5

6

1. Face Cover Assembly 4. Drive Bracket Asy

2.Circuit Board 5. Drive Gear 12x36

3. Motor 6. Drive Gear Cover

1

2

3

4

5

6

1. Cover 6. Air Check

2. Brine Tank 7. Float

3. Brine Well 8. Brine Valve Asy

4. Brine Well Cap 9. Tubing

5. Overow Fitting

7

2

4

PARTS AND FEATURES

Figure 3

Figure 4

Figure 5

Figure 6

1

4

8

2

3

7

5

6

9

Valve Layout Control Layout

Mineral Tank Brine Tank

7

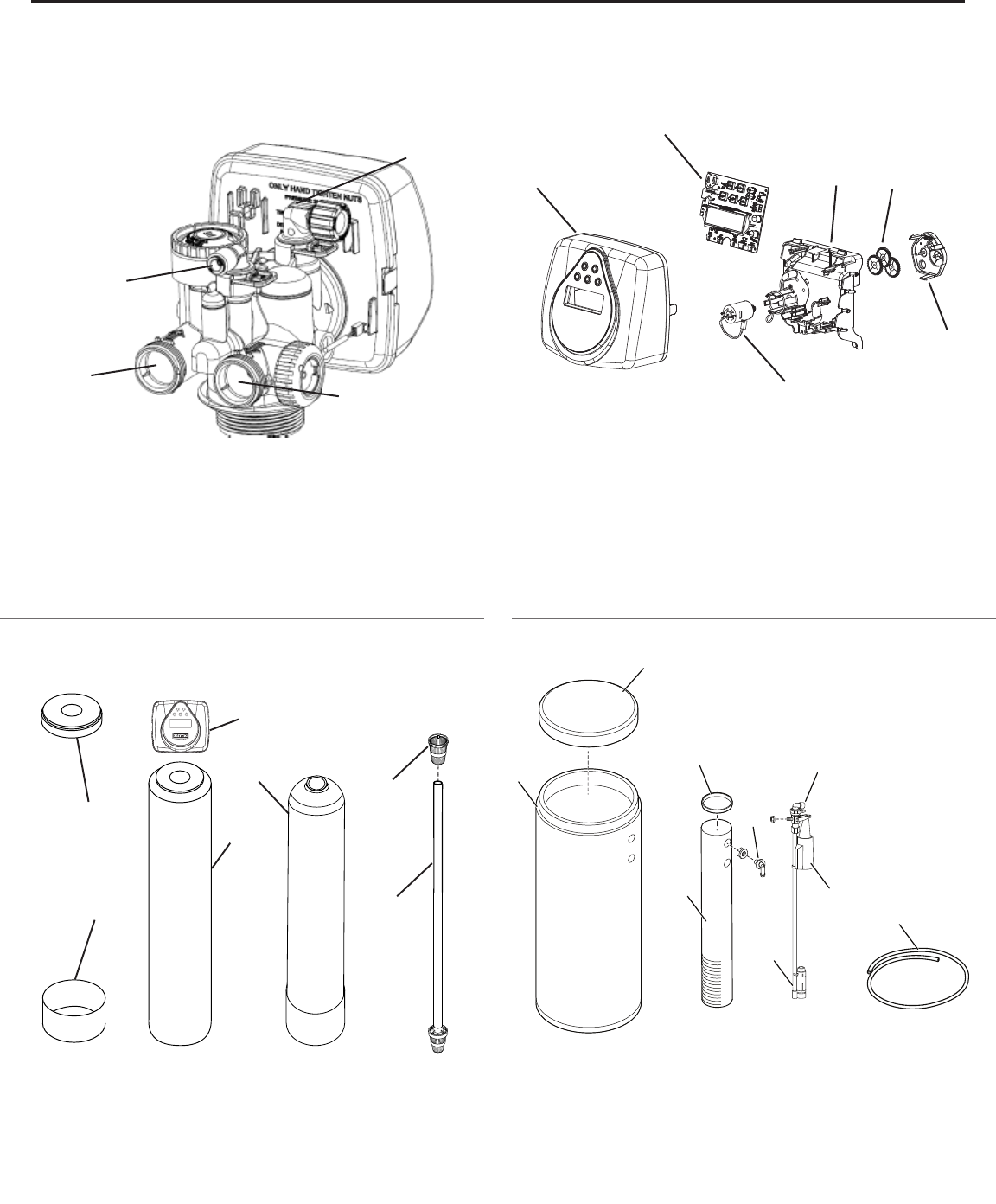

Dimensions 10 x 44” Tank

(25.4 x 111.76 cm)

1 0 x 5 4 ” T a n k

(25.4 x 137.16 cm)

13 x 54” Tank

(33.02 x 137.16 cm)

A 44.25” (112.39 cm) 54.25” (137.79 cm) 54.25” (137.79 cm)

B 52.0” (132.08 cm) 62.0” (157.48 cm) 62.0” (154.9 cm)

C 41.25” (104.77 cm) 41.25” (104.77 cm) 41.25” (104.77 cm)

D 52.0” (132.08 cm) 62.0” (157.48 cm) 62.0” (157.48 cm)

E 47.0” (119.38 cm) 57.0” (144.78 cm) 57.0” (144.78 cm)

F 32.0” (81.28 cm) 32.0” (81.28 cm) 32.0” (81.28 cm)

G 35.31” (89.68 cm) 35.31” (89.68 cm) 35.31” (89.68 cm)

EQUIPMENT DIMENSIONS

A

B

C

E

D

9.7 (24.6)

16.0 (40.6)

16.0 (40.6)

25.7 (65.2)

11.5 (29.2)

Inlet - Outlet

3 (7.6) on Center

NOTE:

7 (17.7) height for

removal of valve cover

Figure 7: Equipment Dimensions

F

G

Dimensions are given in: In (cm)

TM

8

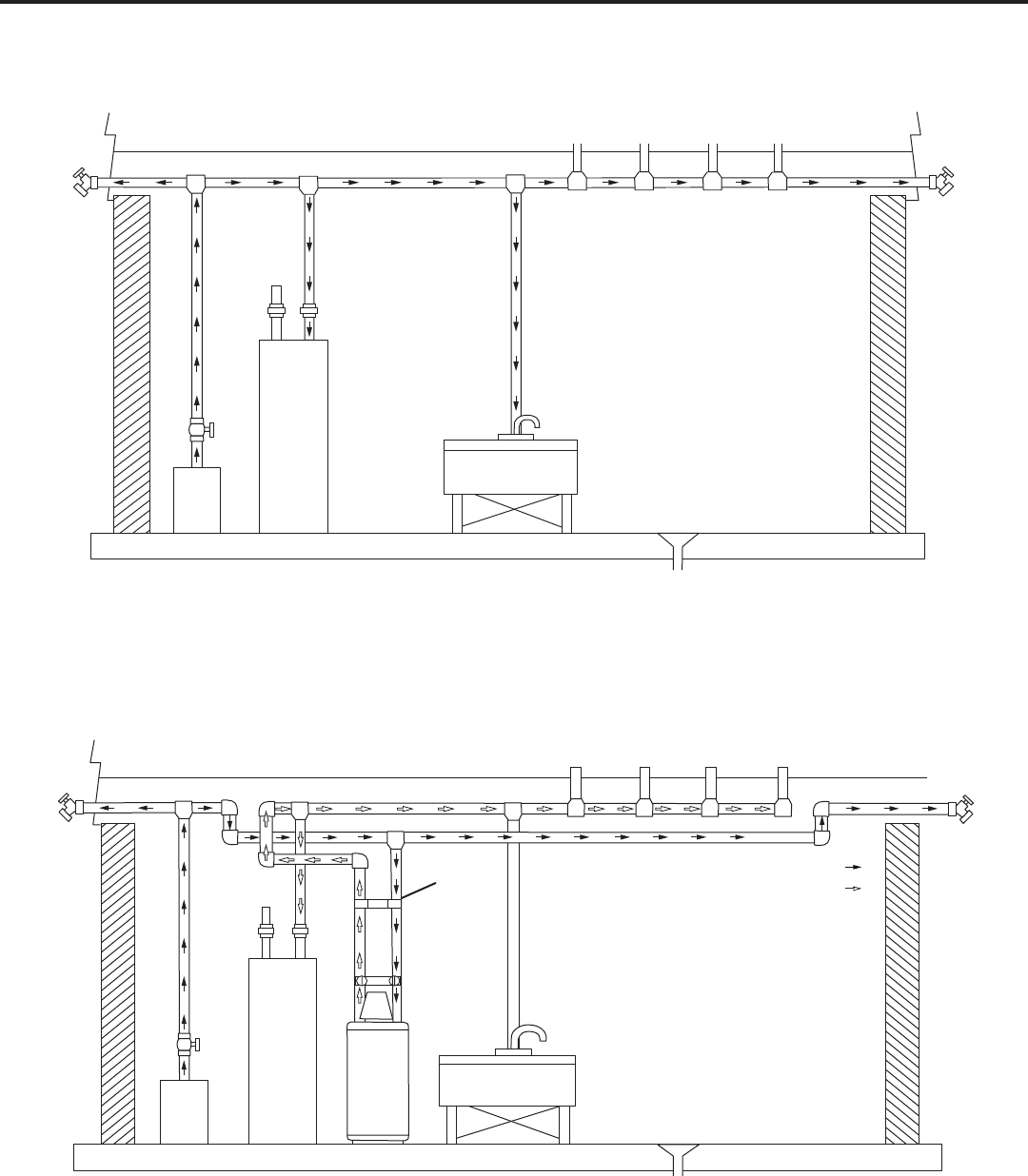

Figure 8: Standard Basement Before Installation (Cold water lines shown)

SYSTEM LAYOUT

Outside

Faucet

Kitchen

Toilet

Bath

Tub

Lavatory

Water

Heater

Hot Water

Outlet

Outside

Faucet

Laundry Tub

Pump

Or

Meter

Floor Drain

Figure 9: Treated Water Flow Diagram

Hot Water

Outlet

Outside

Faucet

Outside

Faucet

Kitchen

Toilet

Bath

Tub

Lavatory

Grounding

Strap

Untreated Water

Treated Water

Water

Rener

Laundry Tub

Water

Heater

Pump

Or

Meter

Floor Drain

Untreated WaterUntreated Water

Treated WaterTreated Water

9

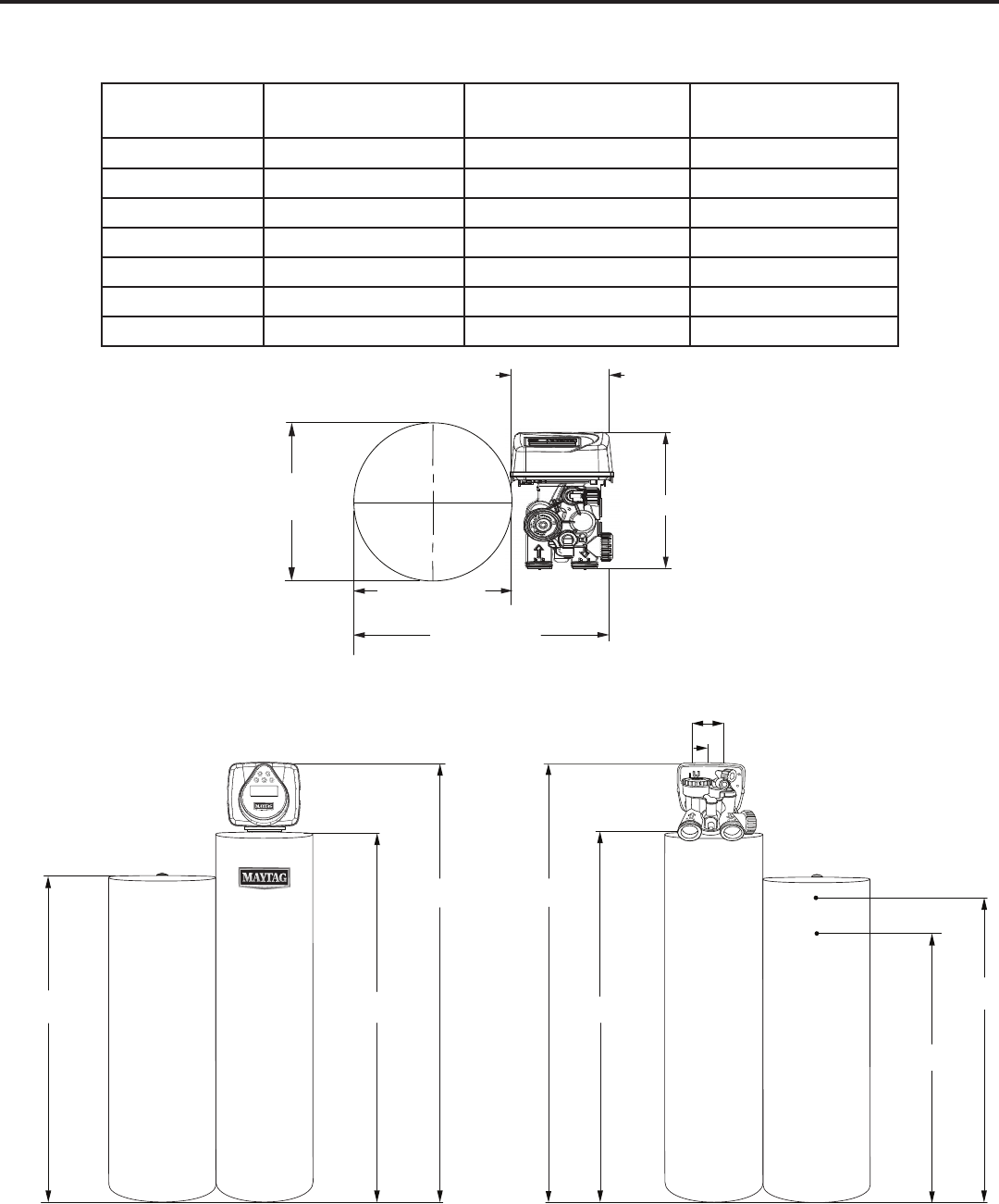

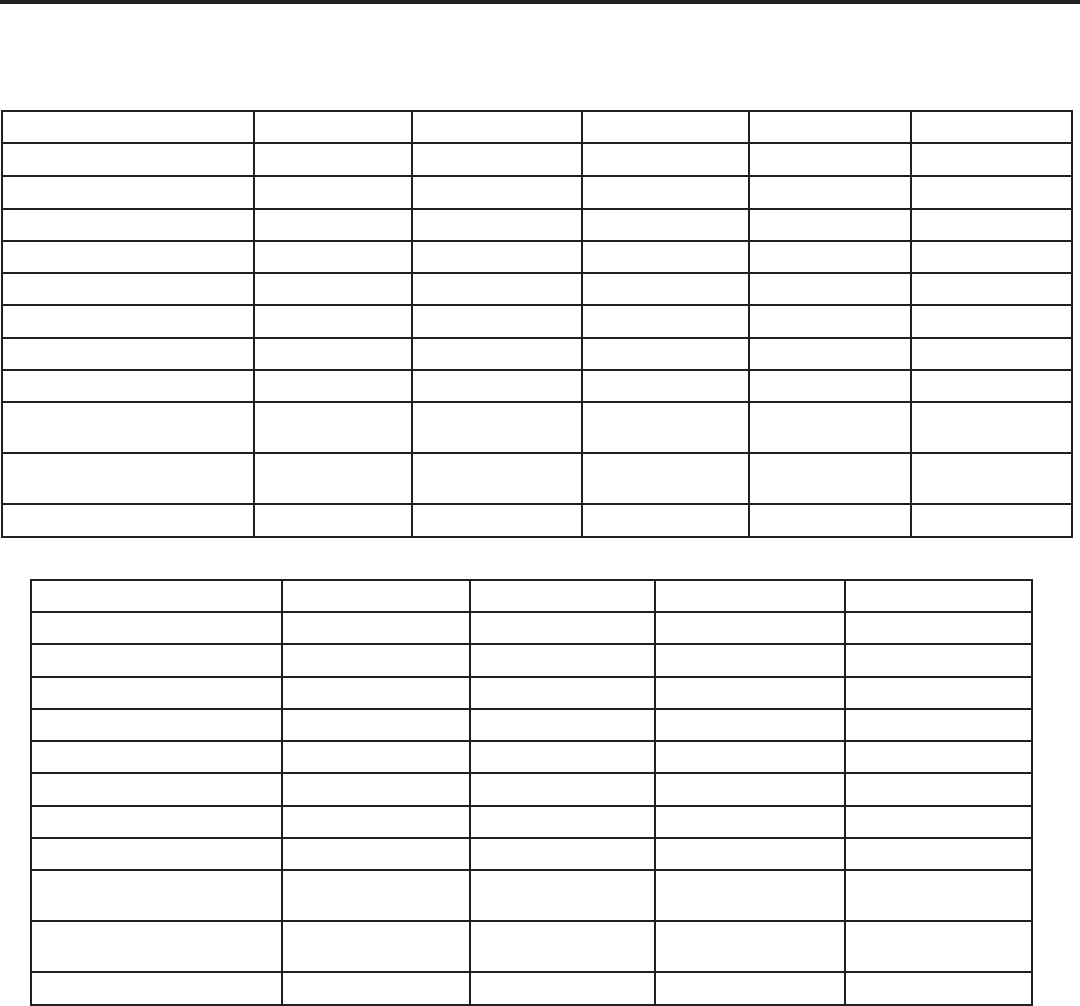

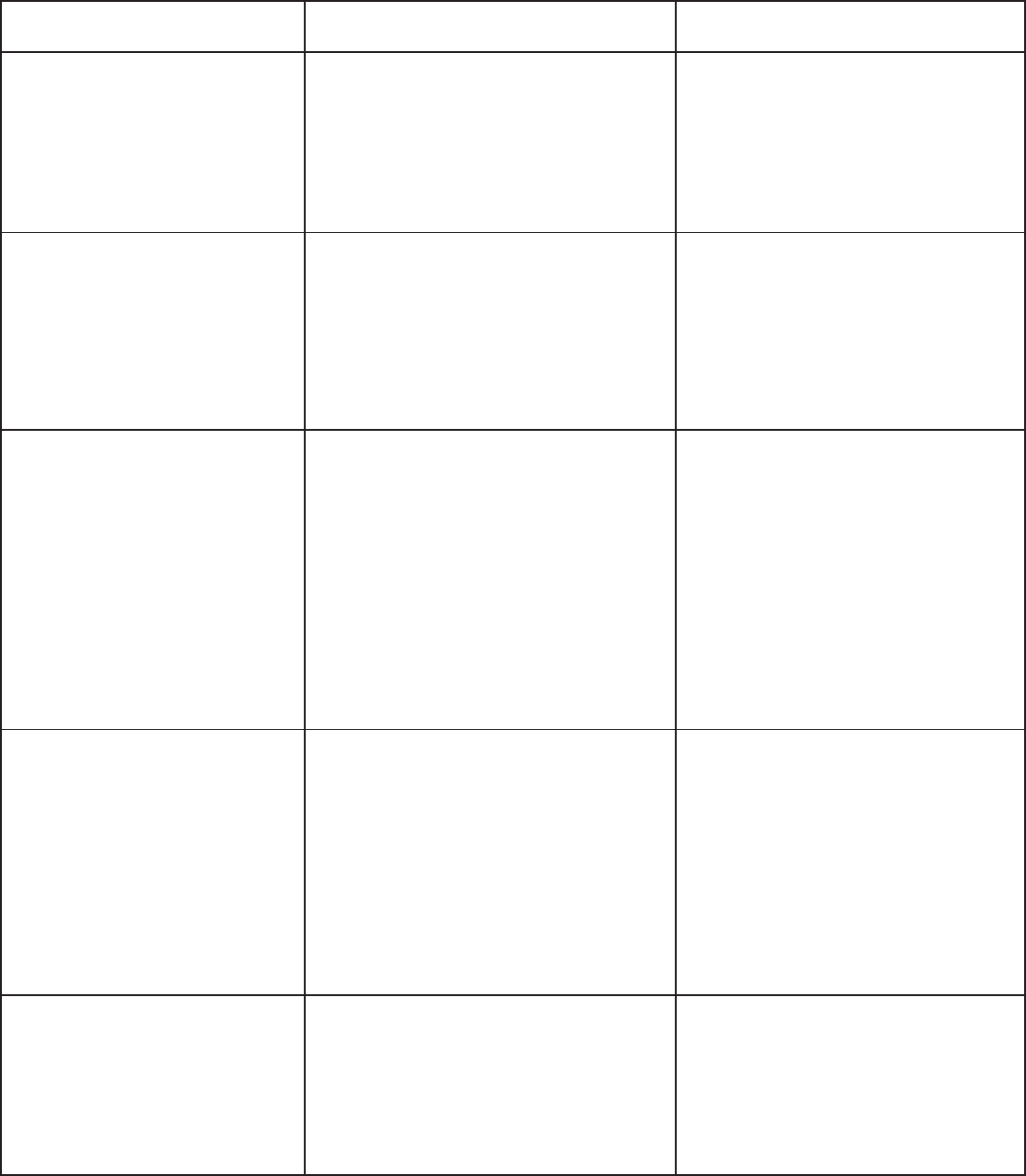

Model Number 3M-ST32-XXX 3M-ST40-XXX 3M-ST48-XXX 3M-ST64-XXX 3M-ST80-XXX

Recharge Style

Mineral Tank Size 10” x 44” 10” x 54” 10” x 54” 13” x 54” 13” x 54”

Resin Volume 1.00 ft³ 1.25 ft³ 1.50 ft³ 2.00 ft³ 2.50 ft³

Recharge (Salt) Tank Size 16” x 40” 16” x 40” 16” x 40” 16” x 40” 16” x 40”

Salt Storage 338 lbs 338 lbs 338 lbs 338 lbs 338 lbs

Drain Water Rate 2.7 gpm 2.7 gpm 2.7 gpm 4.2 gpm 4.2 gpm

Service Connection Size 1” NPT 1” NPT 1” NPT 1” NPT 1” NPT

Drain Connection Size

Recharge (Brine) Connection

Size

Typical Installation Space

Requirement

28”W x 20”D x 62”H 28”W x 20”D x 72”H 28”W x 20”D x 72”H 28”W x 20”D x 72”H 28”W x 20”D x 72”H

Shipping Weight 104 lbs 121 lbs 134 lbs 174 lbs 199 lbs

Model Number 3M-STR32-XXX 3M-STR32XC-XXX 3M-STR40-XXX 3M-STR64-XXX

Recharge Style

Mineral Tank Size 10” x 44” 10” x 54” 10” x 54” 13” x 54”

Resin Volume 1.00 ft³ 1.00 ft³ 1.25 ft³ 2.00 ft³

Recharge (Salt) Tank Size 16” x 40” 16” x 40” 16” x 40” 16” x 40”

Salt Storage 338 lbs 338 lbs 338 lbs 338 lbs

Drain Water Rate 2.7 gpm 2.7 gpm 2.7 gpm 4.2 gpm

Service Connection Size 1” NPT 1” NPT 1” NPT 1” NPT

Drain Connection Size

Recharge (Brine) Connection

Size

Typical Installation Space

Requirement

28”W x 20”D x 62”H 28”W x 20”D x 72”H 28”W x 20”D x 72”H 28”W x 20”D x 72”H

Shipping Weight 116 lbs 127 lbs 133 lbs 192 lbs

SYSTEM SPECIFICATIONS

10

There are no user serviceable parts in the AC adapter,

motor, or PC board, in the event of a failure, these parts

must be replaced.

All electrical connections must be completed

according to the local codes.

the appliance.

Plug the AC adapter into an electrical outlet that is not

Indoor Location Requirements

IMPORTANT:

For indoor location of the Water Treatment System, make

Make sure to maintain the space to access the

equipment for maintenance and adding regenerant

(salt) to brine tank.

Operating ambient temperature: 34°F-120°F

(1°C-49°C).

120 psi (1.38 bar - 8.27 bar).

Maintain constant electrical supply to operate the

control.

Local drain for discharge as close as possible to the

appliance.

Must meet any local and state codes for site of

installation.

Valve is designed for minor plumbing misalignments.

Make sure that all the soldered pipes are fully cooled

before attaching plastic valve to the plumbing.

Outdoor Location Requirements

IMPORTANT:

Place the unit at the dry location only, unless listed as

use.

important measures are taken for outdoor location as

Moisture - Water projected by a nozzle against

operation of the machine.

Direct Sunlight

fade or discolor over time. The integrity of the material

INSTALLATION INSTRUCTIONS

Location Requirements

Electrical Requirements

Temperature - Extreme hot or cold temperature

unreadable but the control must continue to function.

When the temperature returns to normal operating

applications.

Insects and Dust - The controller and valve have

been designed to keep all but the smallest insects out

of the critical areas. Dust is not totally avoidable, but

cover is recommended.

11

IMPORTANT:

inlet port of the valve. When replacing an existing system,

it is possible that the inlet and outlet get exchanged or

plumbing to be installed in an opposite order. Do not

IMPORTANT:

Over time, stress can cause break of the connections.

When the bypass is used, only hand tighten the nuts.

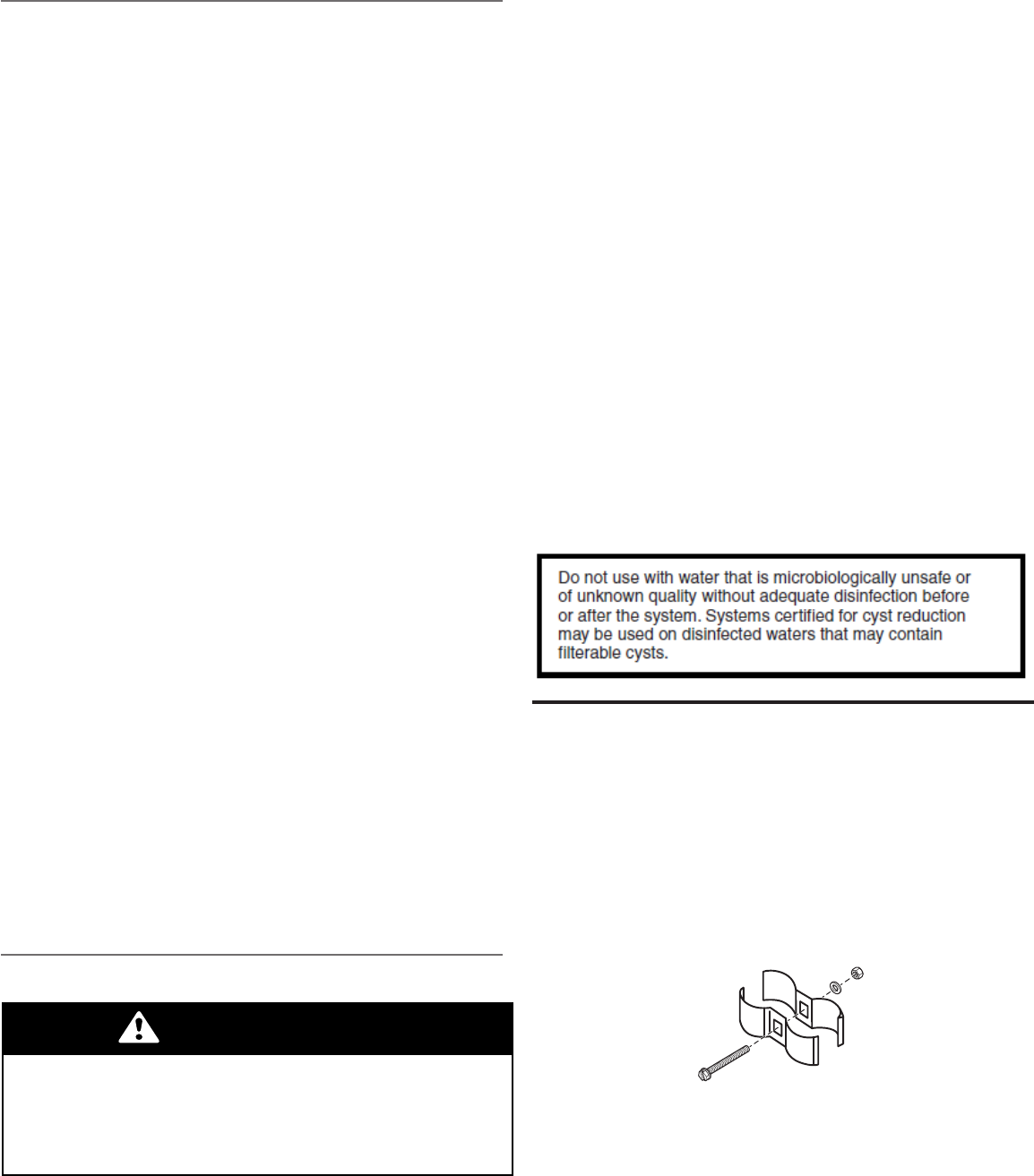

Figure 10

NOTE:

a ground strap must be installed.

The plumbing must be self-supporting and secure

to avoid movement. A piece of metal or a ground

strap is secured to both the inlet and outlet pipes.

(See Figure 10)

IMPORTANT: Make sure that the valve and tank compo-

nents of this unit have been assembled and tightened to

can cause improper valve and tank alignment and can

WARNING

Excessive Weight Hazard

Use two or more people to move and install water

treatment system.

Failure to do so can result in back or other injury.

EQUIPMENT INSTALLATION

Mechanical Requirements

IMPORTANT:

International Plumbing Code and any local codes and

ordinances.

Do not use petroleum based lubricants, oils, or

hydrocarbon based lubricants. Use only 100% silicone

lubricants.

All plastic connections should be hand tightened.

o-ring seal is not used.

NOTE:

the plastic connections.

Soldering near the drain line must be done before

connecting the drain line to the valve. Excessive heat

Refer to the drain line requirements.

connections.

rate is greater than 7 gpm (26.5 Lpm) or the pipe

length is greater than 20 feet (6 m).

It is not recommended to use sealants on the threads.

Use thread seal tape on the threads of the 1” (2.54

threads.

Install appropriate grounding strap across the inlet and

ensure that a proper ground is maintained.

a ground strap must be installed.

General Requirements

Keep the mineral tank in the upright position. Do not

Operating ambient temperature: 34°F - 120°F (1°C -

49°C).

37.8°C).

bar - 8.27 bar).

not use ice melting salt, block salt or rock salt.

the tank.

plumbing adapters) connect to the plumbing system

to set before installing any plastic parts. Do not get

primer or solvent on o-rings, nuts, or the valve.

12

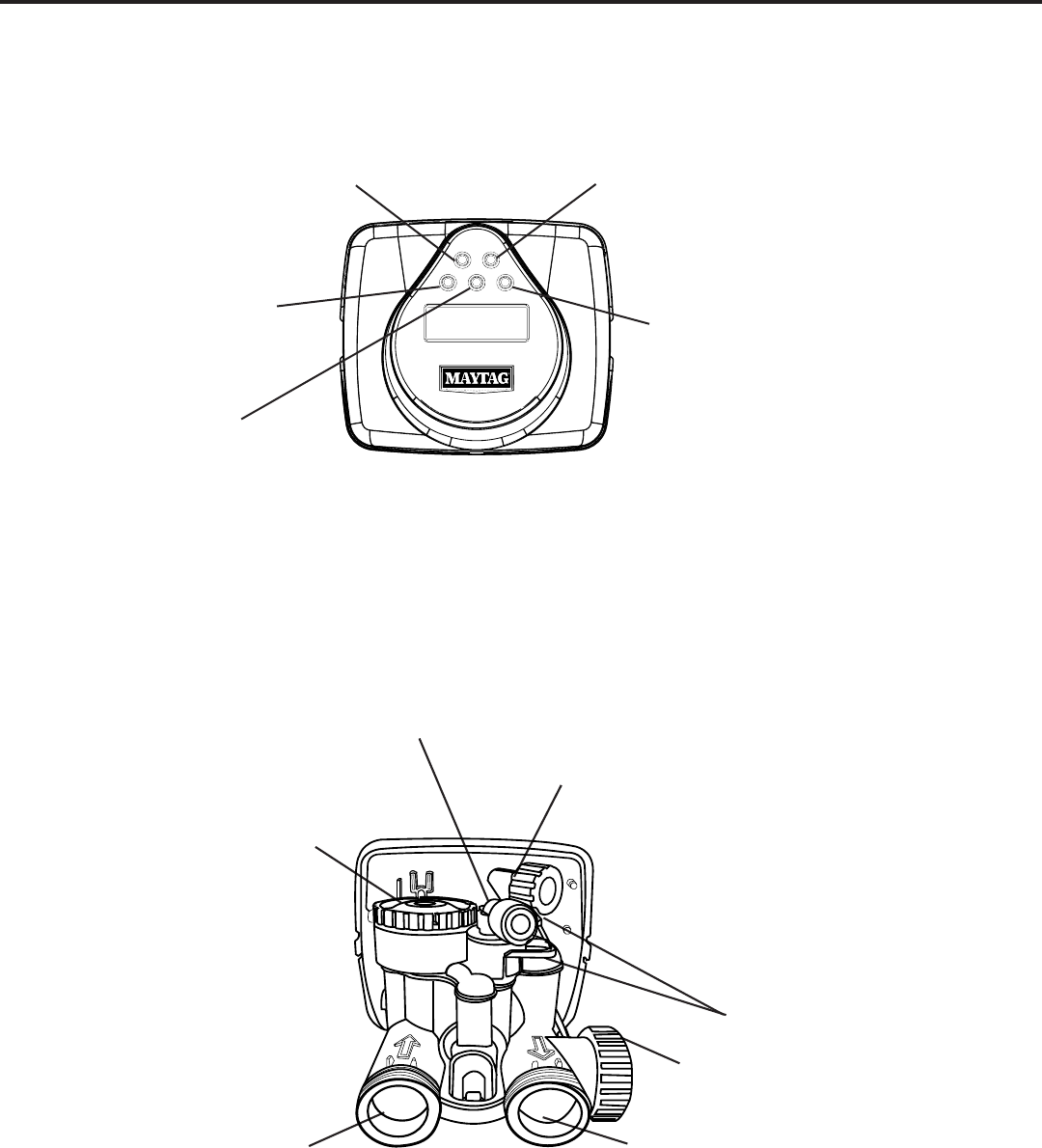

The bypass valve is typically used to isolate the control

to perform control valve repairs or maintenance. The

industry due to its versatility and state of the art design

plumbing misalignments, connections need only hand

tightening.

¹ (or

-

propylene. All seals are self-lubricating EPDM to help

avoid the valve from seizing after long periods of non-

use. Internal o-rings can easily be replaced if service

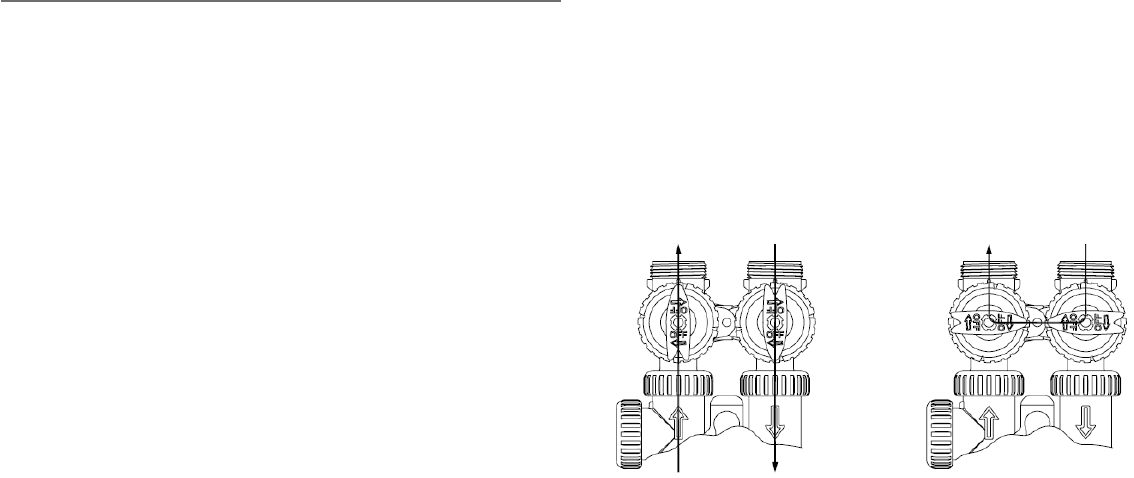

Figure 11

NORMAL

OPERATION

Figure 12

BYPASS

OPERATION

TREATED

WATER

SUPPLY

WATER

ENTERS

SUPPLY

WATER

ENTERS

SUPPLY

WATER

Bypass Valve Operation

is required. One internally lubricated o-ring on the rotor

creates less friction.

operate in four positions.

1. Normal Operation: The inlet and outlet handles point

control valve during normal operation and this posi-

bed during the regeneration cycle. (See Figure 11)

2. Bypass Operation: The inlet and outlet handles point

to the center of the bypass, the control valve is isolat-

system. (See Figure 12)

3. Diagnostic Mode: The inlet handle points in the

to the plumbing. (See Figure 13)

4. Shut O Mode: The inlet handle points to the center

of the bypass valve and the outlet handle points in the

building bypasses the system). (See Figure 14)

IMPORTANT: Do not use petroleum based lubricants.

installing any MAYTAG

®

brand valve. Non-silicone based

lubricants can cause plastic components to fail over time.

NOTE:

Packages”.

NOTE: The MAYTAG

®

system should be installed by

The system is located after the pressure tank (or

heater and the rest of the building.

Place the mineral tank and brine tank in position.

Use the bypass and plumbing adapters and connect

the valve to the building plumbing. Make sure that the

and outlet of the plumbing. “Water Line Connection”.

Connect the brine line. See "Brine Line Connection to

Valve”.

Connection".

"Installation Instructions", “Equipment Installation”,

“System Operation” and “Placing Water System into

Operation”.

13

Figure 13

DIAGNOSTIC

MODE

Figure 14

SHUT OFF

MODE

NO WATER

SUPPLY

WATER

ENTERS

SUPPLY

WATER

SUPPLY

SHUT OFF

FROM THE

VALVE

Figure 16

Brine Line Insertion

Figure 15

Brine Line Connection to Valve

2

1

3

The brine line must be connected from the control valve

to the safety brine valve assembly in the brine tank. Be

sure that the brine line tube is secure and free from air

leaks. Even a small leak may cause the brine line tube to

the brine tank. This may also introduce air into the valve

1. Trim tubing to length. Be sure tubing is free of debris,

past the quad seal.

2. -

ing goes past the quad seal and properly bottoms in

and hold and seal it in place.

3. To remove the tubing, push the collet around the

tubing in and at the same time pull the tubing out.

Figure 17

Safety Brine Valve Assembly

1. 474 Air Check Assy. with ½" (1.27 cm) riser pipe.

2. 474 Safety Brine Valve with ⅜" (0.95 cm) elbow.

3. 474 Float Assy.

Figure 18

Safety Brine Valve

1. Rell Flow (regenerant) Control Fitting

2. Drain Fitting

3. Locking Clip (2) Required

Brine Line and Safety Brine Valve

Connections

Safety Brine Valve Assembly

2

3

1

14

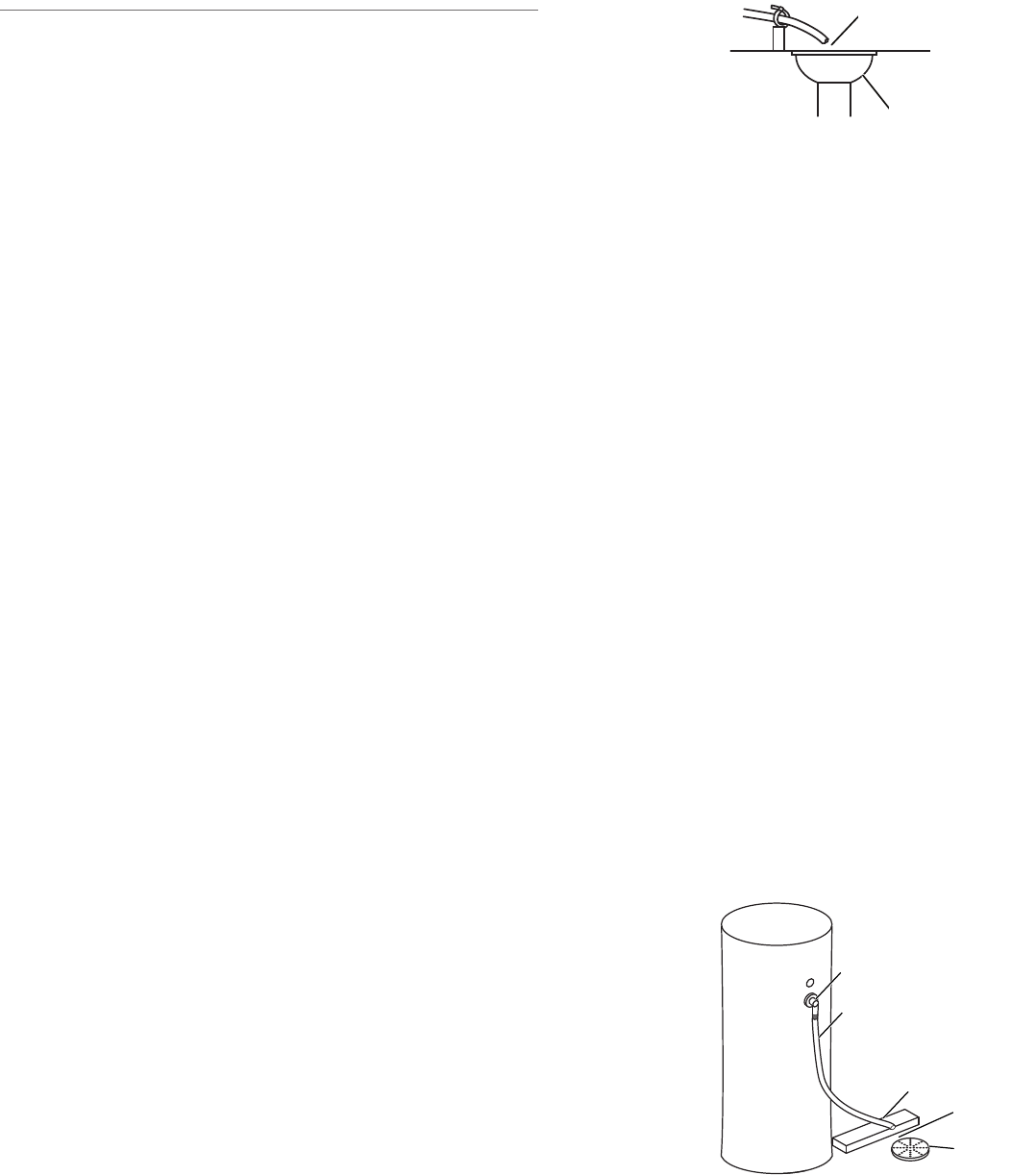

2

1

Overow Fitting

Drain Tubing

Secure hose in place

Air Gap

Drain

Figure 19

Secure Drain Line

NOTE: Standard commercial practices are expressed

-

ing a system.

1. The unit should be above and not more than 40 feet

cm) drain line or the optional nut and poly tube insert

poly tube drain line connection. Use thread seal tape

or CPVC pipe to the drain line connection of the con-

180 degrees so the drain lince can be orientated to

the nearest drain.

2.

or if the unit is located more than 40 feet (12.2 m)

from drain, use ¾" (1.9 cm) tubing, PVC or CPVC

(1.9 cm) tubing, PVC or CPVC pipe to the drain con-

nection of the control valve.

3. The drain line may be elevated up to 6 feet (1.8 m)

providing the run does not exceed 40 feet (12.2 m)

psi (2.76 bar). Elevation can increase by 2 feet (61

pressure at the drain connector.

4. Where the drain line is elevated but empties into a

(17.7 cm) loop at the far end of the line o that the bot-

the hose in place at the drain point. Also provide an

the hose and the drain point.

5.

line, a sink-type trap must be used.

6. Secure the end of the drain line to avoid it from mov-

ing.

In the event of a malfunction, the brine (regenerant) tank

-

line tubing hole on the side of the brine tank.

(See Figure 20)

Drain Tubing sold separately in 100 ft rolls

(Part No. 3PET58100B).

NOTE:

instructions.

Figure 20

Brine Tank with Overow Fitting

Overow Line Connection

Drain Line Connection

1. Overow Fitting 4. Air Gag

2. Drain Tubing 5. Drain

3. Secure hose in place

1

2

3

4

5

1. Air Gap

2. Drain

1

2

Drain Line and Overow Connection

Drain Line Connection

15

1. Overow Fitting 4. Air Gag

2. Drain Tubing 5. Drain

3. Secure hose in place

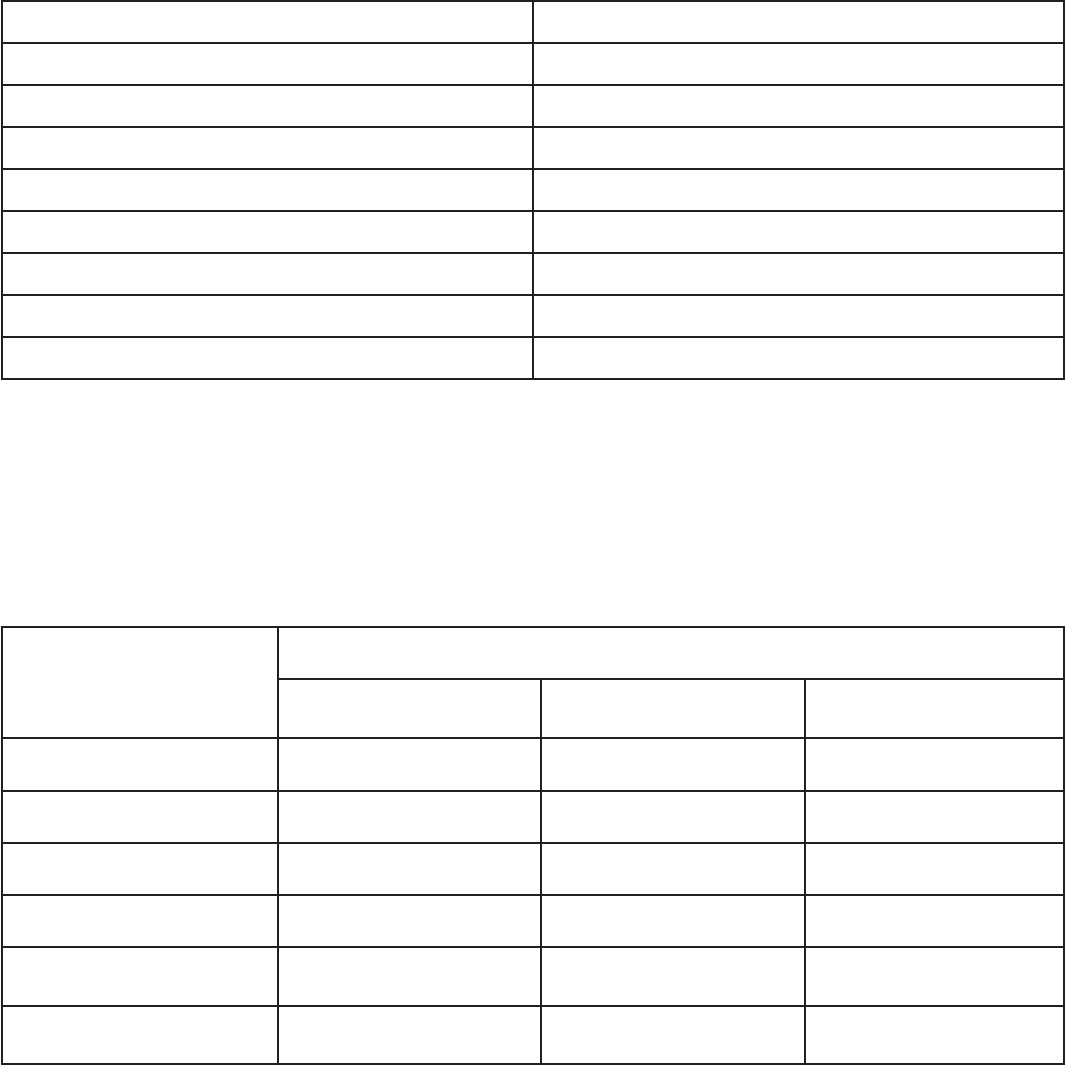

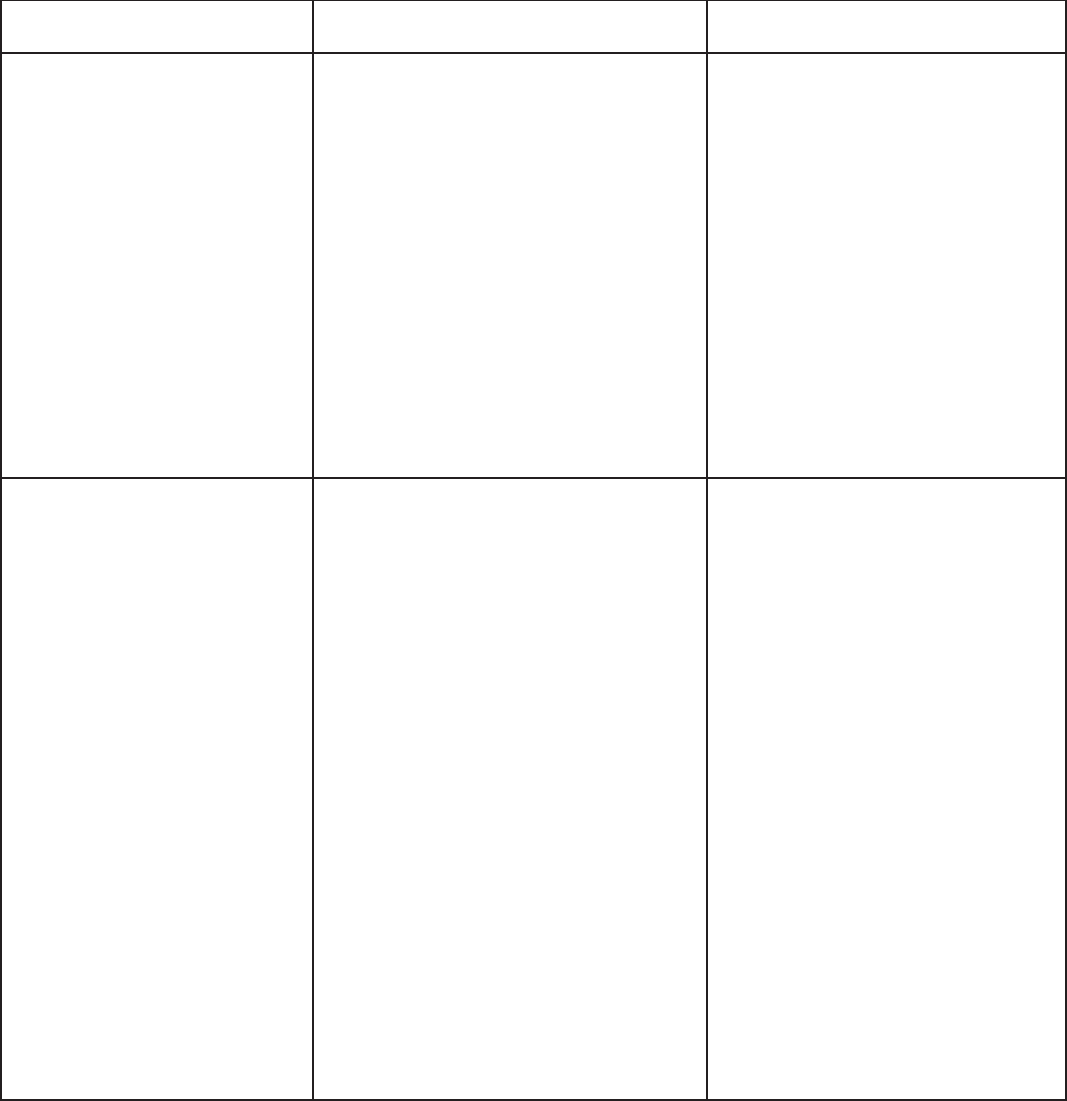

Table

each resin amount.

E = High Eciency salt, approximately 6 lbs.

per cu. ft. of media

S = Standard salt, approximately 9 lbs.

per cu. ft. of media

Q = Quality salt, approximately 15 lbs.

per cu. ft. of media

Media

Volume

(ft) ³

Salt

Setting

Total Salt

Amount Per

Regenera-

tion (lbs)

Estimated

Capacity

(kg)

E 3 10,000

0.5 S 4.5 13,000

Q 7.5 15,000

E 4.5 15,000

0.75 S 7 19,000

Q 11 23,000

E 6 20,000

1.0 S 9 25,000

Q 15 30,000

E 7.5 25,000

1.25 S 11 34,000

Q 19 38,000

E 9 30,000

1.5 S 13.5 38,000

Q 22.5 45,000

E 12 40,000

2.0 S 18 50,000

Q 30 60,000

E 15 50,000

2.5 S 22.5 67,000

Q 37 75,000

E 18 60,000

3.0 S 27 75,000

Q 45 90,000

Table 1

Water Treatment System Set Up: Softening

Media Volume, Salt Amounts and Estimated Capacity

Media Volume, Salt and Capacity Settings Cycles and Softening Set Up

The Maytag® series

treatment professional has the option of having the re-

When setting up the system refer to Table 1 to select the

volume of media, the total salt amount per regeneration

(lbs) and the estimated capacity for the system.

NOTE: The regeneration cycle times are fully adjustable.

Refer to Table 3.

16

Table 3

Regeneration Cycle Times in Units

Table 2

System Cycles

1st Cycle: Fill Rinse (0:00:15 SEC)

Dissolve Brine

Rinse (0:00:15 SEC)

3rd Cycle: Rinse

4th Cycle: Rinse 5th Cycle: Service

Fill (0:00:05 SEC)

5th Cycle: Service

Cycle

Range

Softening

Filtering-Regenerant

oFF, 1 - 120 (Minutes) oFF, 1 - 120 (Minutes) oFF, 1 - 120 (Minutes)

oFF, 1 - 180 (Minutes) oFF, 1 - 180 (Minutes)

Rinse oFF, 1 - 120 (Minutes) oFF, 1 - 120 (Minutes) oFF, 1 - 120 (Minutes)

Fill (Regenerant) oFF, 0.1 - 200.0 (lbs) oFF, 0.05 - 20.00 (gals)

Softening 1 - 480 (Minutes)

Filtering 1 - 480 (Minutes) 1 - 480 (Minutes)

17

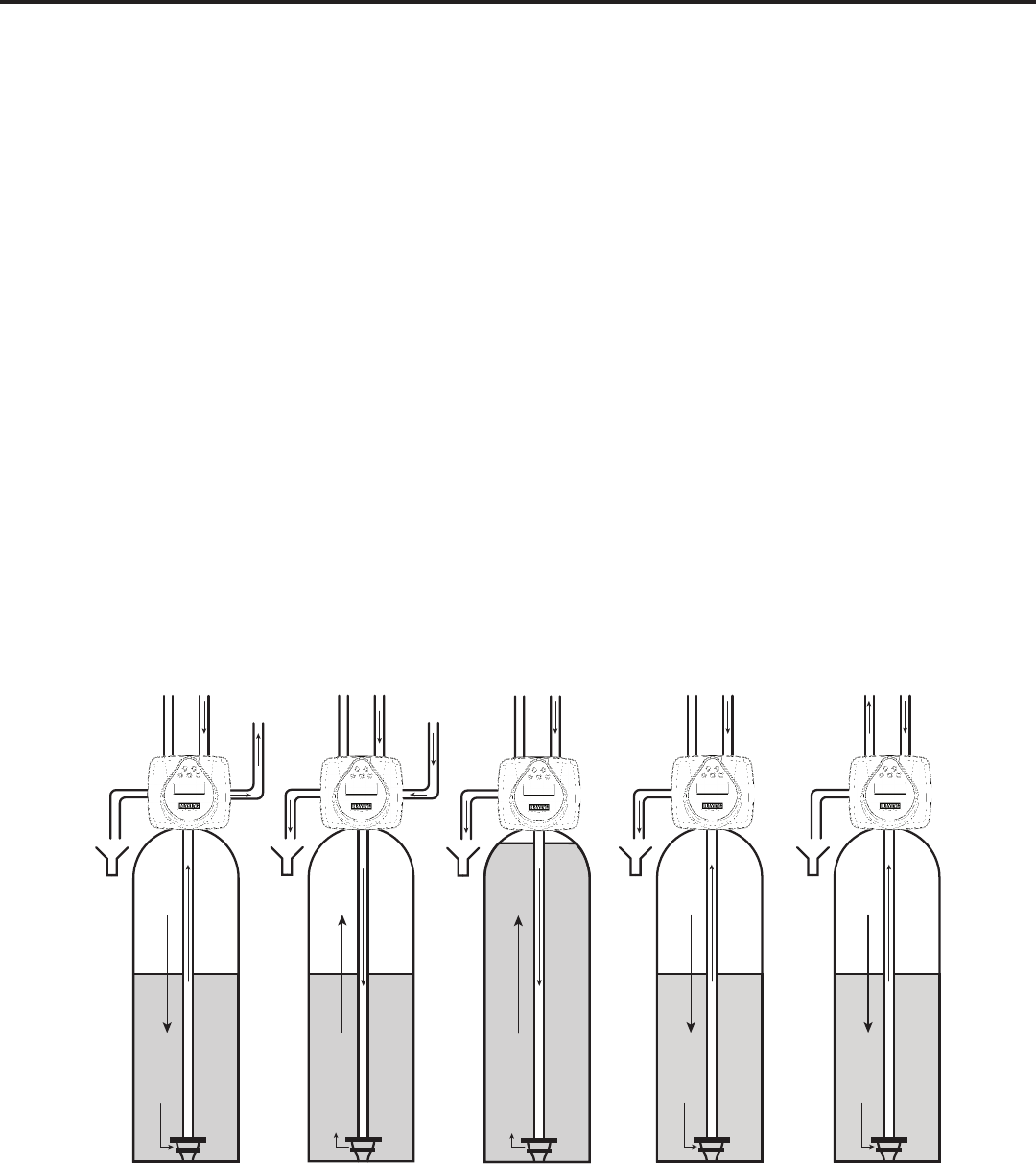

Fill/Dissolve Water

Regenerate (Upow)

drain. The hardness ions are displaced by sodium ions and are sent to the drain. The resin is regenerated

Backwash (Upow)

Rinse (Downow)

the drain. Any remaining brine residual is rinsed from the resin bed.

Service (Downow)

as it passes through the resin bead.

Figure 21

Cycle Water Flows

To

Regenerant

Tank

Fill/Dissolve

From

Regenerant

Tank

Regenerate

Backwash

ServiceRinse

SYSTEM OPERATION

18

General Programming Instructions

These procedures are:

Once the Cycle Sequence has been set, the other procedures can be accessed in any order. Details on each of the

-

and CLOCK in sequence.

incorporated.

To quickly exit Softener Setup, Diagnostics or Valve History press CLOCK. Any changes made prior to the exit are

incorporated.

the preset regeneration procedure. It is possible to do a double regeneration if the control valve is set to “NORMAL” or

“NORMAL + “On 0” in Softener System Setup or Filter System Setup. To do a double regeneration:

2. Press and hold the “REGEN” button for three seconds until the valve regeneration initiates.

-

generation time.

are being used, and that the injector plug(s) are in the correct location. Refer Figure 29 & Figure 30.

Proportional Brining

brining.

Press NEXT to go to the next step. Press REGEN to return to the previous step.

Cycle Sequence Diagnostics

Softener System Setup Valve History

User Display Settings

19

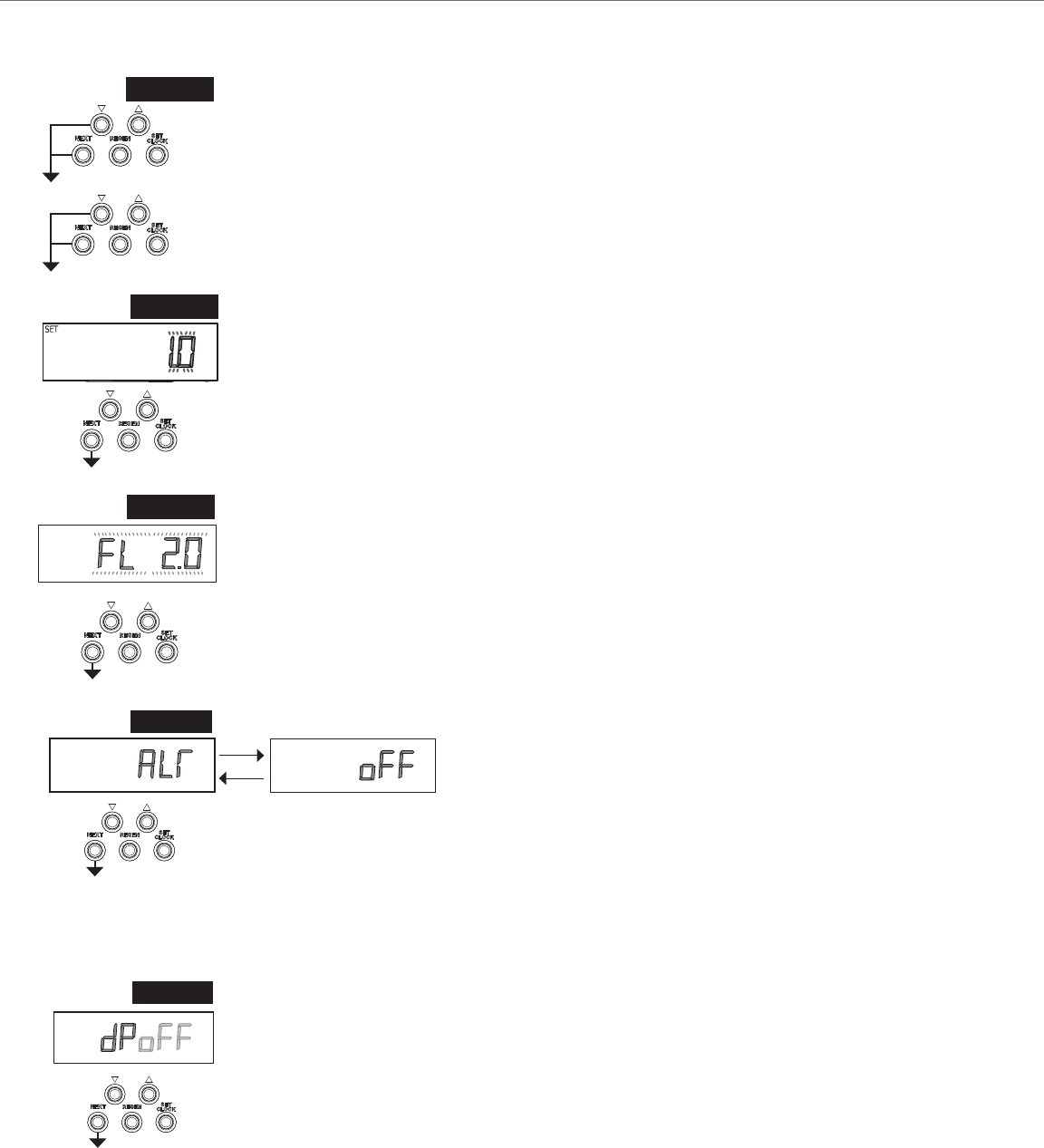

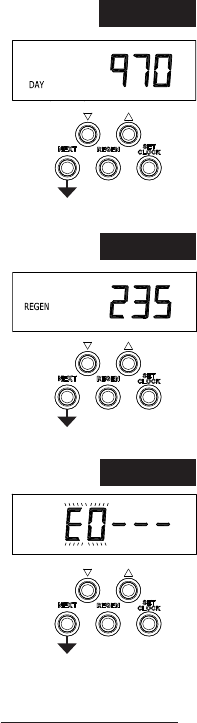

STEP 1C

Step 1C

Step 2C

(SET TO 1.0)

Press NEXT to go to next Step. Press REGEN to return to exit Cycle Sequence.

STEP 2C

Step 3C

(Variable Meter Calibration.) Variable meter pulses of 0.1-150.0 PPG can be selected.

STEP 3C

Step 4C –

• the Control Valve to act as an alternator; or

• the Control Valve to have a Separate Source during the

regeneration cycle; or

(SET TO oFF)

Press NEXT to go to Step 5C. Press REGEN to return to exit

Cycle Sequence.

STEP 4C

SET

STEP 5C

SET

SET

SET

Step 5C – dp Select OFF using the

(SET TO oFF)

Press NEXT to go to Step 6C. Press REGEN to return to previous step.

SET

Cycle Sequence

20

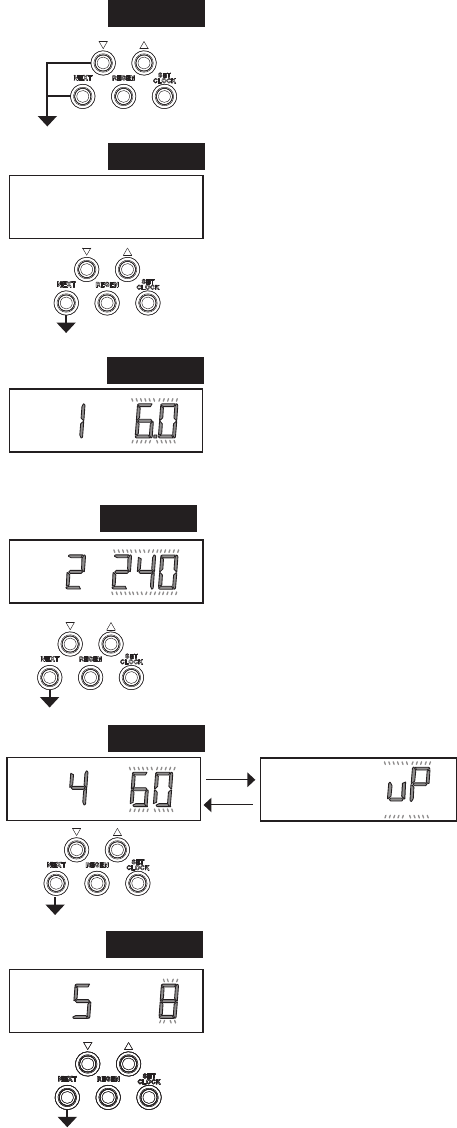

Step 6C

(SET TO PrE)

Press NEXT to go to Step 7C. Press REGEN to return to previous step.

Step 7C

(SET TO uP)

regenerant piston, and stack are being used, and that the injector or injector plug(s) are

Press NEXT to Return to NORMAL MODE. Press REGEN to return to previous step.

STEP 6C

STEP 7C

RETURN TO

NORMAL MODE

SET

FILL

REGEN

SET

REGEN

BRINE

.

Step 6C Step 7C Cycle Order

Post dn

Pre dn

Post UP

Pre UP

NOTE:

the Grains Capacity display (Step 8S).

Softener System Setup

21

STEP 1S

Step 1S – Press NEXT and simultaneously for 3 seconds and release. If screen in Step

2S does not appear in 5 seconds the lock on the valve is activated. To unlock press ,

NEXT,

and release.

STEP 2S

Step 2S.

(SET TO SOFTENING)

Press NEXT to go to Step 3S. Press REGEN to exit Softener System Setup.

STEP 4S

Step 3S or .

Refer to Table 1 for salt setting.

(SET LBS OF SALT)

Press NEXT to go to Step 4S. Press REGEN to exit Softener System Setup.

Step 4S

using or .

time.

(FACTORY SET TO 240 MIN)

Press NEXT to go to Step 5S. Press REGEN to exit Softener System Setup.

STEP 3S

Step 5S

using or .

and brine direction (dn or uP).

(SET TO UP)

Press NEXT to go to Step 6S. Press REGEN to return to

previous step.

STEP 5S

SET

LBS

FILL

SET

SOFTENING

SET

BRINE

MIN

SOFTENING

SET

MIN

BRINE

SET

REGEN

BRINE

Step 6S

or .

Press NEXT to go to Step 7S. Press REGEN to return to previous step.

STEP 6SSTEP 6S

SET

MIN

BACKWASH

22

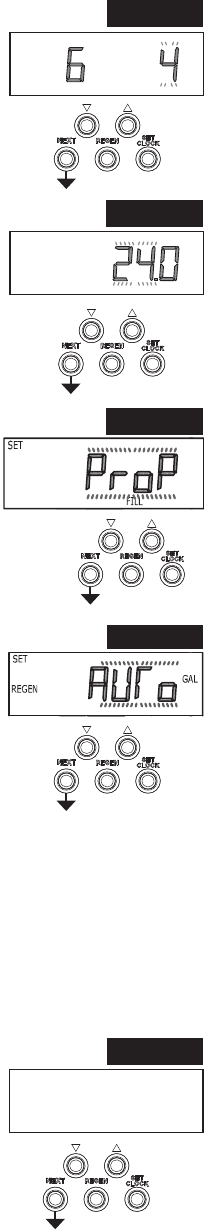

Step 7S

Press NEXT to go to Step 8S. Press REGEN to return to previous step.

Step 8S

The capacity and hardness levels entered are used to automatically calculate reserve capacity

Refer to Table 1 for capacity setting.

(SET CAPACITY)

Press NEXT to go to Step 9S. Press REGEN to return to previous step.

Step 9S

(SET TO ProP)

Press NEXT to go to Step 10S. Press REGEN to exit Softener System Setup.

Step 10S

estimated;

Refer to Programming: Installer Settings Step 3I; or

Step 2I.

appear.

Refer to Setting Options Table

(SET TO AUTO)

Press NEXT to go to Step 11S. Press REGEN to return to previous step.

Step 11S If value is set to:

or

Refer to Setting Options Table for more detail.

“on 0” is the default if Step 2C is set to 1.0T, and “NORMAL + on 0” is not available.

(SET TO NORMAL)

Press NEXT to go to Step 12S. Press REGEN to return to previous step.

STEP 7S

STEP 8S

STEP 9S

STEP 10S

STEP 11S

SET

MIN

RINSE

SET

CAPACITY

x1000

SET TIME

REGEN

NORMAL

23

Step 15S: Set the Service Call Indicator by using or . Range

is in ¼ of a year increments from 0.25 to 9.75 years. Selecting

Press NEXT to go to Step 16S. Press REGEN to return to

previous step.

RETURN TO

NORMAL MODE

STEP 15S

Step 12S – Set Relay operation using or . The choices are:

• Set Time: After the start of a regeneration the amount of time that

should pass prior to activating the relay. The start of regeneration is

• Set Softening Gal: Relay activates after a set volume has been used

and the set time period has expired.

• Set Softening Regen Gal: Relay activates after a set volume has been

• Set HoLd Gal: Relay closes every set number of gallons and releases

is pressed.

(SET TO OFF)

Press NEXT to go to Step 13S. Press REGEN to return to previous

step.

STEP 12S

Step 13S: Set Relay Actuation Time or Gallons using or The choices are:

• Relay Actuation Time: After the start of a regeneration the amount of time that should pass

• Relay Actuation Gallons: Relay activates after a set number of gallons have passed.

Ranges from 1 to 100 gallons.

• Relay HoLd: Relay closes every set number of gallons. Ranges from 1,000 to 99,000,000

gallons.

Press NEXT to go to Step 14S. Press REGEN to return to previous step.

STEP 13S

Step 14S: Set Relay Deactivate Time using or .

Ranges from 1 second to 500 minutes.

• Does not display for HoLd Gal selection.

Press NEXT to go to Step 15S. Press REGEN to return to previous step.

STEP 14S

Step 16S: Displays time remaining before a service call is requested. To reset the time

NOTE:

reminder screen is displayed.

STEP 16S

SET

SET

24

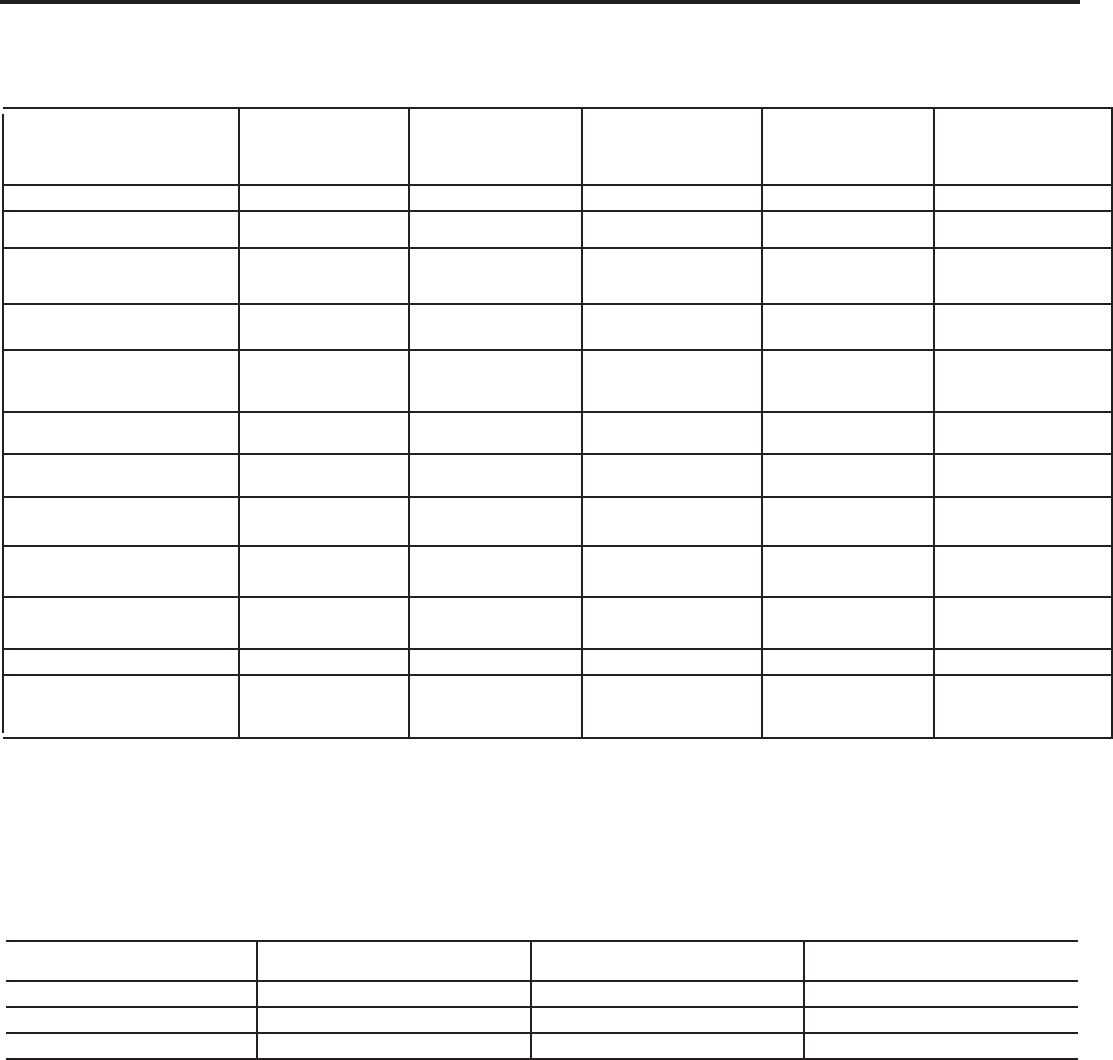

1

SETTING OPTIONS TABLE

1

System Type

Regeneration

Option

Regeneration

Type

Day

Override

Softening Auto Normal 1-28 days

Regeneration occurs at the next

Softening Auto Normal OFF

Regeneration occurs at the next

Softening or

Filtering

20 - 1,500,000

Gallons

Normal 1-28 days

Regeneration occurs at the next

Softening or

Filtering

20 - 1,500,000

Gallons

Normal OFF

Regeneration occurs at the next

reaches 0.

Softening or

Filtering

OFF Normal 1-28 days

Time Clock operation.

Regeneration occurs at the next

days is reached.

Softening

Auto or

20 - 1,500,000

Gallons

On 0 1-28 days

Softening or

Filtering

20 - 1,500,000

Gallons

On 0 OFF

volume capacity reaches 0.

Softening Auto Normal + On 0 1-28 days

Regeneration occurs at the next

regeneration occurs after 10 minutes of no

0.

Softening or

Filtering

20 - 1,500,000

Gallons

Normal + On 0 1-28 days

Regeneration occurs at the next

days is reached or regeneration occurs after

capacity reaches 0.

Softening Auto Normal + On 0 OFF

Regeneration occurs at the next

regeneration occurs after 10 minutes of no

0.

25

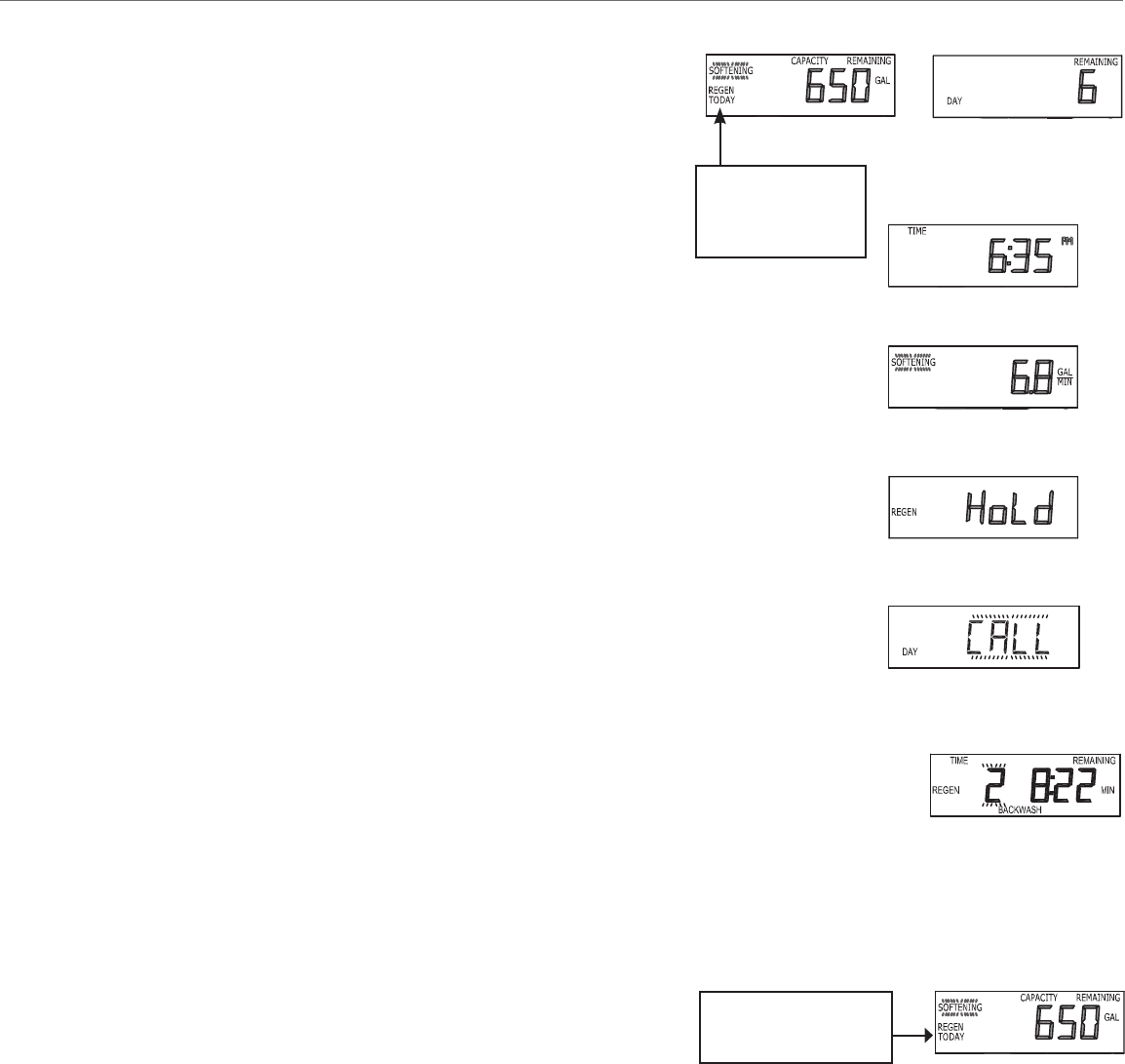

General Operation

Days remaining is the number of days left before the system goes

be treated before the system goes through a regeneration cycle.

closed.

display.

the system).

or

REGEN TODAY

regeneration is

expected “Tonight.”

Flash if a regeneration

is expected “Tonight.”

Regeneration Mode

regeneration process and the time remaining for that step to be completed. The system runs through the steps

Manual Regeneration

the system calls for it, usually referred to as manual regeneration. There

laundry day.

“NORMAL

regenerate immediately. The request cannot be canceled.

NOTE:

regenerating.

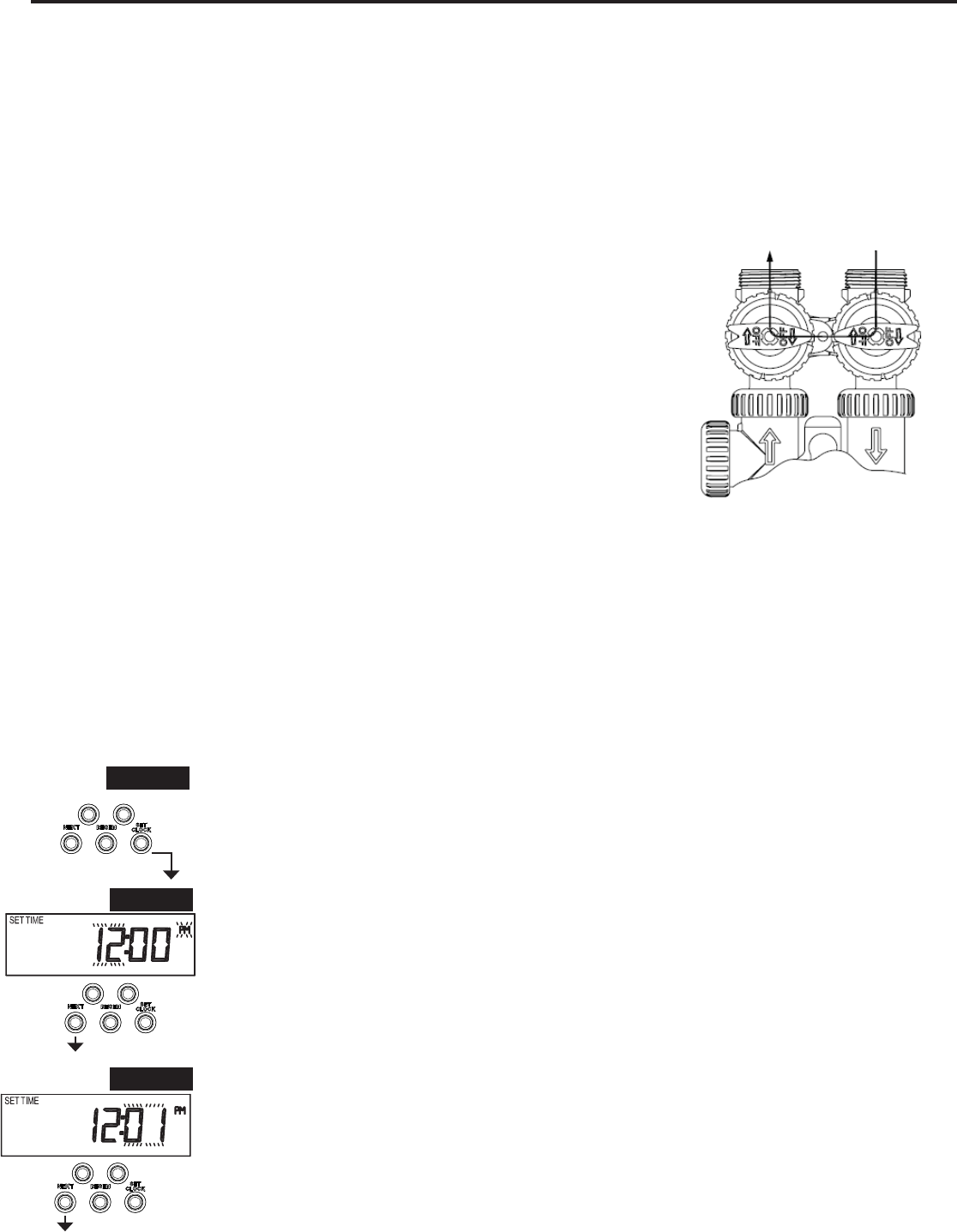

User Display Settings

26

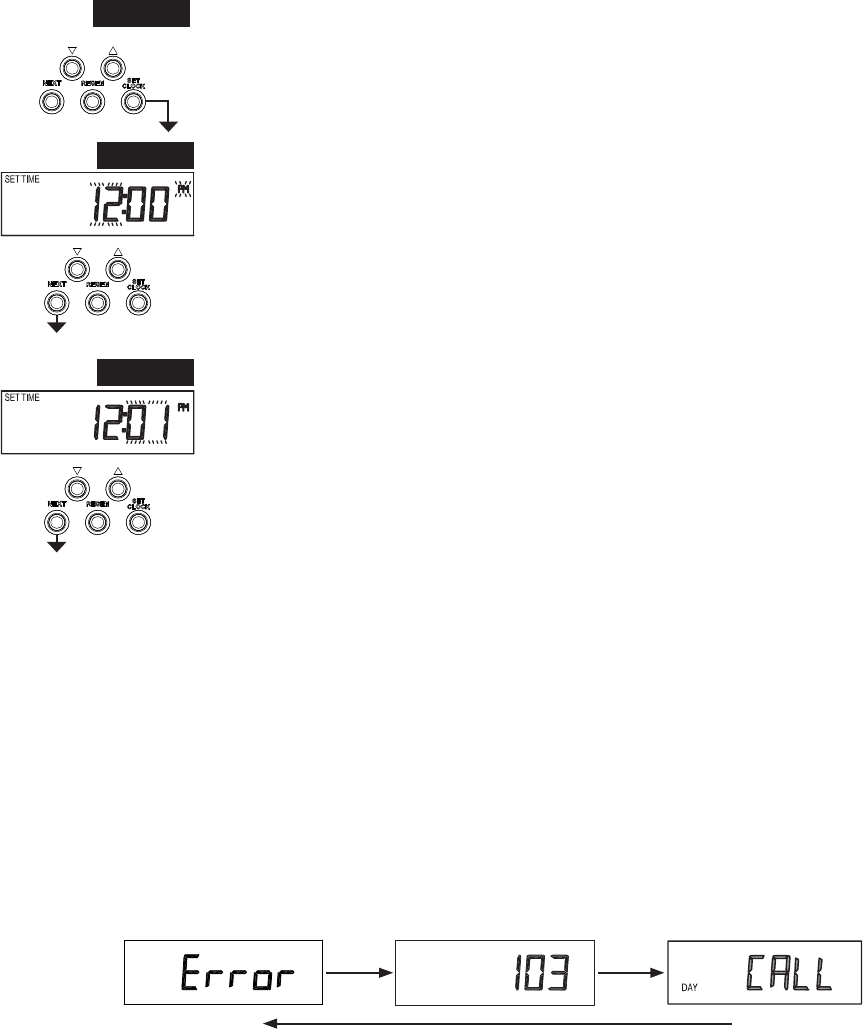

Set Time of Day

The user can also set the time of day. Time of day should only need to be set if the battery has been depleted because

be replaced.

STEP 1U

STEP 2U

STEP 3U

RETURN TO

NORMAL MODE

STEP 1U – Press SET CLOCK.

STEP 2U - Current Time (hour): Set the hour of the day using or

after 12. Press NEXT to go to Step 3U.

STEP 3U - Current Time (minutes): Set the minutes of the day using or . Press

NEXT to exit Set Time of Day. Press REGEN to return to previous step.

Power Loss

Error Message

27

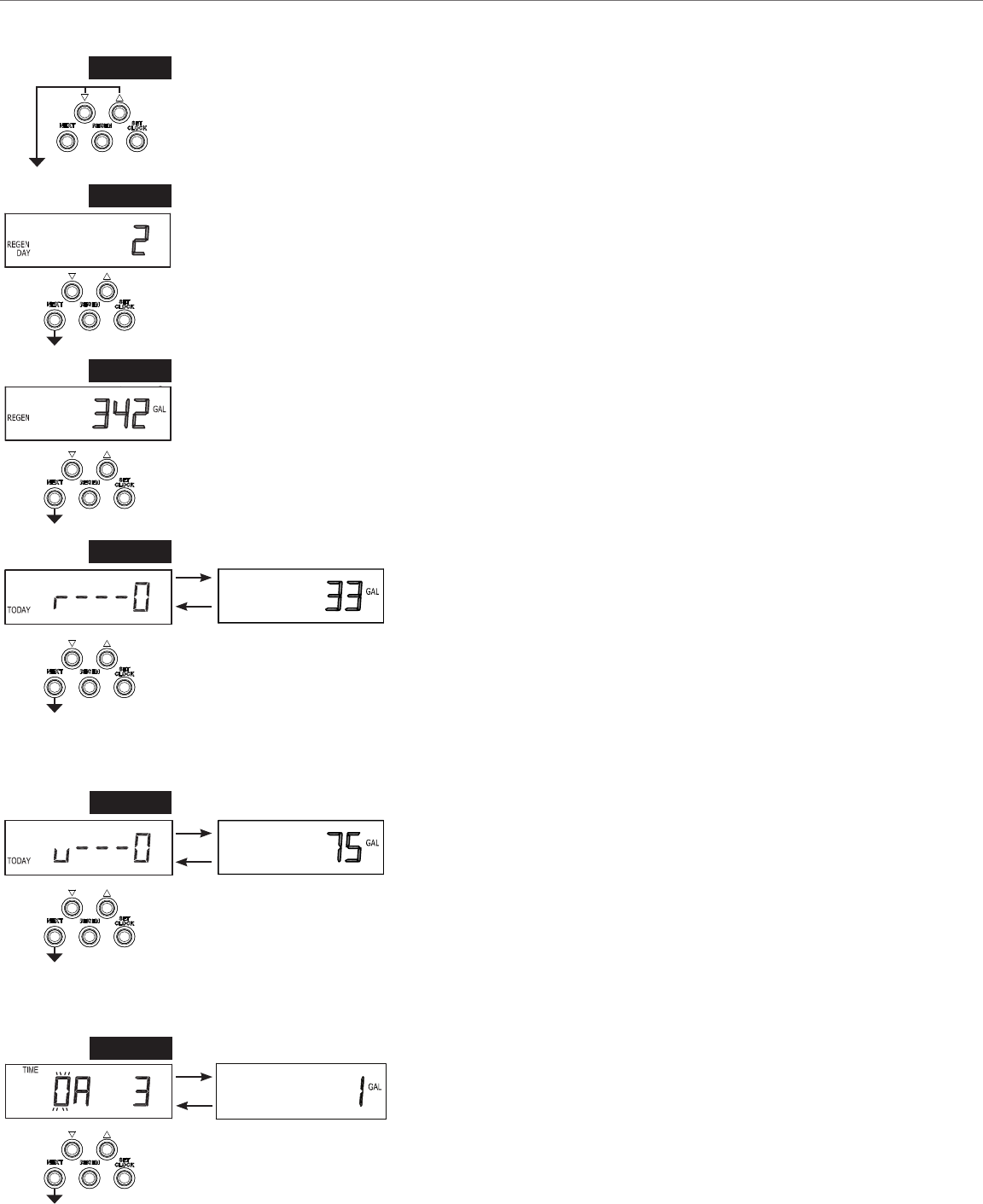

STEP 1D

NEXT,

CLOCK in sequence, then

STEP 1D

STEP 2D

STEP 2D

regeneration occurred. Press NEXT to go to Step 3D. Press REGEN to exit Diagnostics.

STEP 3D

STEP 3D

installed. Press NEXT to go to Step 4D. Press REGEN to return to previous step.

STEP 4D

STEP 4D – Volume, reserve capacity used for last 7 days: If the valve

is set up as a softener, a meter is installed and Set Volume Capacity

time to go to Step 5D. Press REGEN to return to previous step.

STEP 5D

STEP 5D

6D. Press REGEN to return to previous step.

STEP 6D

Press NEXT to go to Step 7D. Press REGEN to return to previous step.

STEP 6D

Diagnostics

28

STEP 8D

9D. Press REGEN to return to previous step.

STEP 8D

STEP 9D

NEXT to go to Step 10D. Press REGEN to return to previous step.

STEP 9D

STEP 10D

regenerations that have occurred since startup. Press NEXT to go to Step 11D. Press REGEN

to return to previous step.

STEP 10D

STEP 7D

meter is not installed. Press NEXT to go to Step 8D. Press REGEN to return to previous step.

STEP 7D

STEP 11D – MAV Drive History in the direction of extended piston rod

move is displayed as “1710”. Press NEXT at any time to go to Step

12D. Press REGEN to return to previous step.

Press and hold

11D to reset the MAV drive history in both the retracted

drive history data for retracted and extended rod position

press and hold REGEN and

NEXT to advance display to the old MAV drive history.

STEP 11D

29

Press and

User Display.

RETURN TO

NORMAL MODE

STEP 12D

STEP 12D – MAV Drive History in the direction of retracted piston

12D to reset the MAV drive history in both the extended and retracted piston rod position.

Press NEXT at any time exit Diagnostics. Press REGEN to return to previous step.

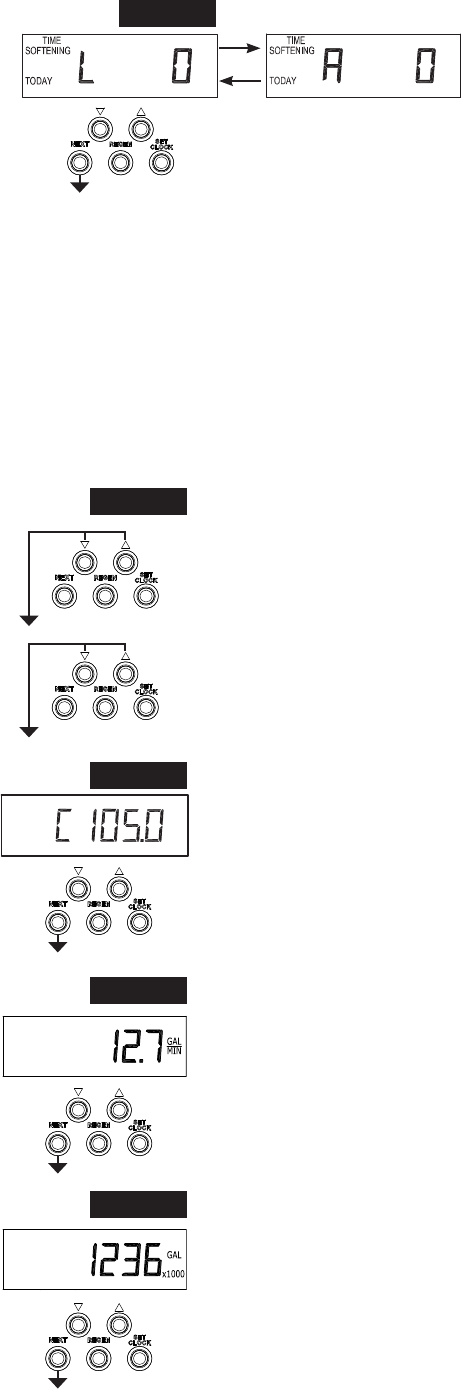

STEP 1VH

simultaneously and release.

STEP 1VH

STEP 2VH

2

Press NEXT to go to Step 3VH. Press REGEN to exit Valve History.

STEP 3VH

meter is not installed. Press NEXT to go to Step 4VH. Press REGEN to return to previous

step.

STEP 4VH

to Step 5VH. Press REGEN to return to previous step.

STEP 2VH

STEP 3VH

STEP 4VH

Valve History

30

STEP 5VH

Press NEXT to go to Step 6VH. Press REGEN to return to previous step.

STEP 5VH

2

Values in steps 2VH through 7VH cannot be reset.

RETURN TO

NORMAL MODE

STEP 6VH

number of regenerations that have occurred since startup. Press NEXT to go to Step 7VH.

Press REGEN to return to previous step.

STEP 7VH

Valve History. Press REGEN to return to previous step.

STEP 6VH

STEP 7VH

31

Open the inlet ball valve.

Close the inlet boiler drain.

Close the outlet ball valve.

Figure 22

to the right

Open the outlet boiler drain on the outlet side of the system.

a bucket or garden hose to purge color, cement, sealants or solder

residue.

Once the lines are clear close the outlet boiler drain.

position proceed to the next section.

1. Flush water lines

NOTE:

Figure 22

2. Plug in, initialize, and set time on the water system control

STEP 1U – Press CLOCK.

STEP 1U

STEP 2U

STEP 3U

RETURN TO

NORMAL MODE

STEP 2U - Current Time (hour): Set the hour of the day using ▼or ▲

after 12. Press NEXT to go to Step 3U.

STEP 3U - Current Time (minutes): Set the minutes of the day using or . Press

NEXT to exit Set Time of Day. Press REGEN to return to previous step.

PLACING WATER SYSTEM INTO OPERATION

index the piston to the service cycle..

SUPPLY

WATER

ENTERS

SUPPLY

WATER

32

3. Fill mineral tank, purge air, backwash and rinse to ush lines

Press and hold REGEN button more than 3 seconds until the motor starts. Wait until the motor stops and display

Press and release the REGEN button each time the motor stops to advance through each cycle until you reach the

“BACKWASH” cycle. Once in the “BACKWASH” cycle.

IMPORTANT:

proceed to next step.

back in. Then press and release the REGEN button, once the motor stops, press and release the REGEN button

completely clear.

Continue to next section.

4. Brine cycle check & initial brine tank ll

NOTE:

Press and hold the REGEN button more than 3 seconds until the motor starts. Wait until the motor stops and

display

Maytag

®

series codirect

When Pre Fill is selected in set up press and release the REGEN button to advance to the next cycle. Each time

the motor stops, press and release the REGEN button to advance through each cycle until you reach the “BRINE”

cycle

Continue to next section.

33

5. Brine cycle check & initial brine draw

With the controller in the “BRINE” cycle, check to see that

troubleshooting section.

REGEN button to advance to the next cycle. Each time the motor stops, press

and release the REGEN button again until you reach the “SERVICE” position.

(Refer to Figure 23)

Check all plumbing for leaks.

Place salt (regenerant) in the brine tank. Replace cover on brine tank securely.

Continue to next section.

SUPPLY

WATER

ENTERS

“TREATED”

WATER

EXITS

Figure 23

6. To Sanitize and Disinfect the System (last step after placing the system into operation)

Depending upon the conditions of use, the style of Water Treatment Sytem, the type of ion exchanger, and the

Sodium or Calcium Hypochlorite

5.25% Sodium Hypochlorite.

These solutions are available under trade names such as Clorox*. If stronger solutions are used, such as those sold

for commercial laundries, adjust the dosage accordingly.

• Dosage

• Regenerant tank conditioners

*Clorox is a trademark of the Clorox Company.

Calcium Hypochlorite

Calcium hypochlorite, 70% available chlorine, is available in several forms including tablets and granules. These solid

• Dosage

• Regenerant tank

34

7. Programming: Installer Settings

time of day is programmed on page 26.

STEP 2I

STEP 5I

STEP 6I

STEP 3I

STEP 1I - Press NEXT and ▲ simultaneously for 3 seconds.

STEP 2I – Hardness: Set the amount of hardness in grains of hardness as calcium carbonate

per gallon using ▼ or ▲

Note: The grains per gallon can be increased if soluble iron needs to be reduced. This display

Capacity in Softener System Setup.

Press NEXT to go to step 3I. Press REGEN to exit Installer Display Settings.

STEP 3I – Day Override: When volume capacity is set to “oFF”, sets the number of days

AUTO or to a number, sets the

maximum

used to call for a regeneration. Set Day Override using ▼ or ▲:

• “oFF”.

Refer to Setting Options Table for more detail on setup.

Press NEXT to go to step 4I. Press REGEN to return to previous step.

STEP 4I – Backlight Operation: Set the normal activity of the backlight. Set to ON, the backlight

Press NEXT to go to Step 5I. Press REGEN to return to previous step.

STEP 5I – Next Regeneration Time (hour): Set the hour of day for regeneration using ▼ or ▲.

selected in Set Regeneration Time Option in Softener System Setup or Filter System Setup.

Press NEXT to go to step 6I. Press REGEN to return to previous step.

STEP 6I – Next Regeneration Time (minutes): Set the minutes of day for regeneration using

▼ or ▲

Softener System Setup or Filter System Setup.

Press NEXT to exit Installer Display Settings. Press REGEN to return to previous step.

STEP 4I

STEP 1I

RETURN TO

NORMAL MODE

The MAYTAG

®

35

4

3

1

2

5

FRONT

BACK

Figure 24

Figure 25

5

2

6

4

3

1. Regen Button 4. Up Button

2. Next Button 5. Set Clock

3. Down Button

7

1

1. Inlet 5. Locking Clip (2) Required

2. Injector Cap 6. Meter Assembly

3. Brine Fitting w/Nut 7. Outlet

4. 3/4 inch Drain Line Flow Control Assembly

DRAWINGS AND PART NUMBERS

Control Valve - Front and Back View

36

Front Cover and Drive Assembly

Drawing No. Mfg. Part No. Description Quantity

1 V4378 Front Cover Assembly 1

2 V3107-01 Motor 1

3 V3002-A Drive Bracket Asy 1

4 V4404LD-BOARD LD PC Board 1

5 V3110 Drive Reducing Gear 12x36 3

6 V3109 Drive Gear Cover 1

7 V3106-01 Drive Bracket & Spring Clip 1

V3186-06 1

V3946 Wide Backplate 1

PC Board Relay

Terminal Block

1

5

6

7

3

2

4

1

2

3

4

5

6

7

Battery replacement is

3 volt lithium coin cell

type 2032.

Correct

Battery

Orientation

When replacing the battery, align

Figure 26

There are no user serviceable parts are on the PC board, the motor or the AC adapter.

U.S. International

Supply Voltage 100-120 VAC 100-240 VAC

Supply Frequency

Output Voltage 15 VDC 15 VDC

Output Current 500 mA 500 mA

Relay Driver Output Type – Single Solid-State 12VDC

Relay Driver Output Capacity - 12VDC @100mA.

NOTE: Check for proper mounting dimensions on valve back

plate prior to mounting an external relay under control cover.

PC Board Relay

Terminal Block

Relay

RLY 1 Coil -

COM Coil +

Control Valve - Front Cover and Drive Assembly

37

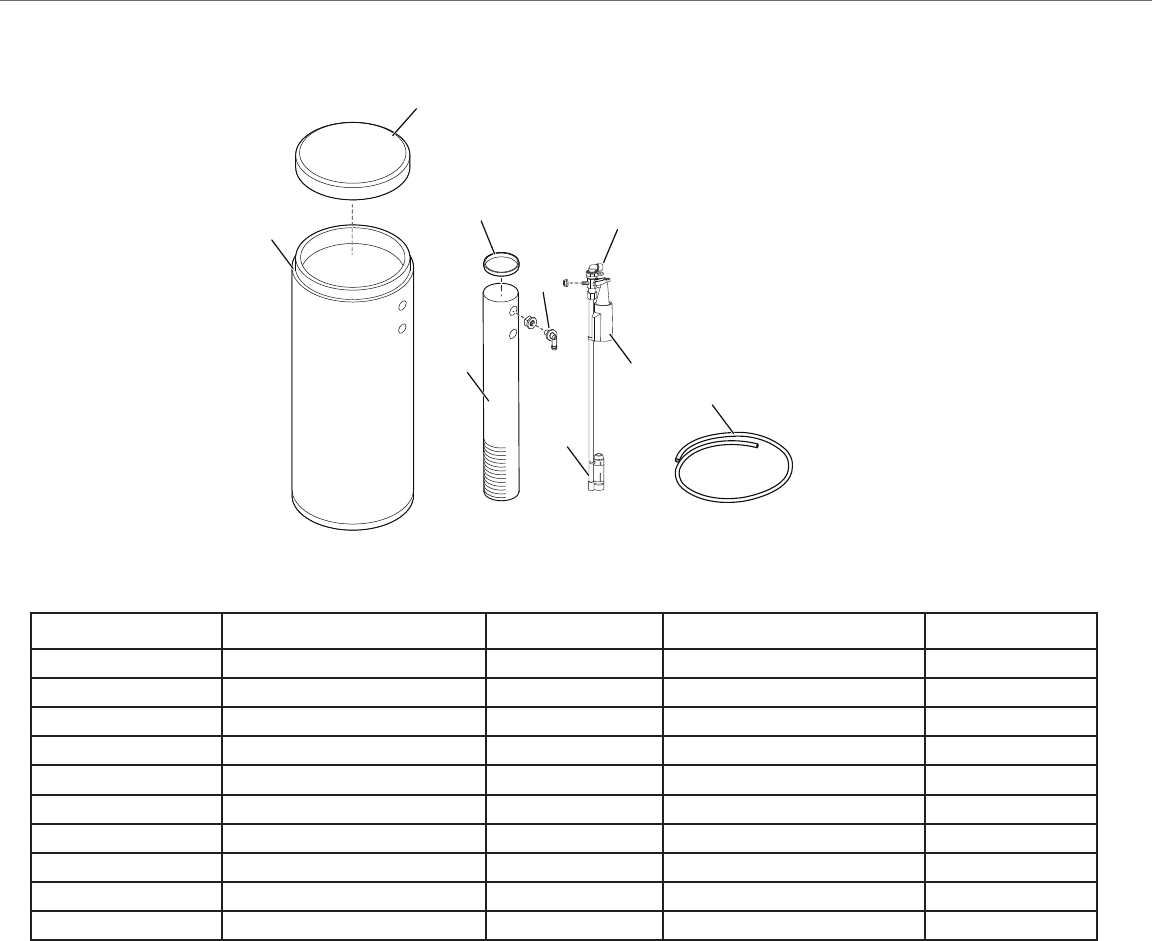

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3BTCVR16GRAYNL-M 1

***2 3BTASY1640MOBILGREY 1

3 3BW436SL H1030-36S 1

4 3BWCAP4 H7016 Brine Well Cap 2

5 3OF2PC H1018 1

6 3BVACPU474 H4500-48 Air Check Assembly 1

7 3BVFLOAT4749 H4640-9.5 1

8 H4600 1

**9 3PET38BLK100 2T20-0604BK Tubing 1

* 3LLB-M-BT_2.85X11.85 309060 Brine Tank Cover Label 1

need to be ordered separately

Brine Tank Assembly and Parts List

1

4

8

2

3

7

5

6

9

Figure 27

38

3

5

2

1

8

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3TDD1203 Top Distributor 1

*2 3DIST10554ST Distributor Assembly 1

*3

3TJCAPGRAY Tank Jacket Cap Cool Gray 10 inch 1

3TJCAPGRAY13INCH Tank Jacket Cap Cool Gray 13 inch

*4 3TJSLEEVEMOBILGRAY Tank Jacket Sleeve 10" Mobil Gray 1

*5

3TJBM1044MOBILGRAY Tank Jacket 10 x 44 Mobil Gray

1

3TJBM1054MOBILGRAY Tank Jacket 10 x 54 Mobil Gray

3TJBM1354MOBILGRAY Tank Jacket 13 x 54 Mobil Gray

**6 3LLB-M-TJ_4.5X1.6331 Tank Jacket Label 1

* **7 3TJBMFOAMSTRIP25FT Foam strips for Tank Jacket

(Length varies by Model)

*8

3MT1044PK12 Mineral Tank 10 x 44

1

3MT1054PK12 Mineral Tank 10 x 54

3MT1354PK12 Mineral Tank 13 x 54

9 3CVWTHRCVR-LD-COOLGRAY Mid Size Weather Cover Cool Gray 1

* Varies by Model

9

Figure 28

4

Mineral Tank Assembly, Valve Cover, and Parts List

39

Drawing No. Part No. Mfg Part No. Description Quantity

1 3CVSPACERSTACKV3005 V3005 Spacer Stack Assembly 1

2 3CVDRIVECAPASYV3004 V3004 Drive Cap Assembly 1

3 V3496 Drive Back Plate 1

4a 3CVPISTONDWNFLOW3011 V3011

(solid amber color)

1

4b 3CVPISTONUPFLOW30110 V3011-01

(black & amber color)

1

5 3CVPISTONREGENV3174 V3174 Regenerant Piston 1

6 V3135 O-Ring 228 1

7 3CVTNKADPTORINGV3180 V3180 O-Ring 337 1

8 3CVBPFTG ORINGV3105 V3105 O-Ring 215 (Distributor Tube) 1

9 V3001 1

V3001UP 1

NOTE: V3004 drive cap assembly includes o-ring 228

9

3

9

4a

4b

1

6

2

5

7

8

Figure 29

Drive Cap, Piston, Regenerant Piston and Stacker Assembly

Control Valve - Drive Cap, Piston, Regenerant Piston, and Stacker Assembly

40

and 013 (upper) o-ring.

NOTE:

located in the UP hole and injector plug is in the other hole.

Drawing No. Part No. Mfg Part No. Description Quantity

1 3CVINJCAPV3176 V3176 Injector Cap 1

2 3CVORINGINJBPV3152 V3152 O-Ring 135 1

3 3CVINJSCREENV3177-01 V3177-01 Injector Screen Cage 1

4 3CVINJASYV3010-1Z V3010-1Z Injector Asy Z Plug 1

5

3CVINJASYCV3010-1A V3010-1A Injector Asy A Black 1

3CVINJASYCV3010-1B V3010-1B 1

3CVINJASYCV3010-1C V3010-1C Injector Asy C Violet 1

3CVINJASYCV3010-1D V3010-1D Injector Asy D Red 1

3CVINJASYEV3010-1E V3010-1E Injector Asy E White 1

3CVINJASYFV3010-1F V3010-1F Injector Asy F Blue 1

3CVINJASYGV3010-1G V3010-1G 1

3CVINJASYHV3010-1H V3010-1H Injector Asy H Green 1

3CVINJASYIV3010-1I V3010-1I Injector Asy I Orange 1

3CVINJASYJV3010-1J V3010-1J Injector Asy J Light Blue 1

3CVINJASYCV3010-1K V3010-1K Injector Asy K Light Green 1

V3170 O-Ring 011 *

V3171 O-Ring 013 *

1

2

3

4

5

Figure 30

Control Valve - Injector Cap and Injector

41

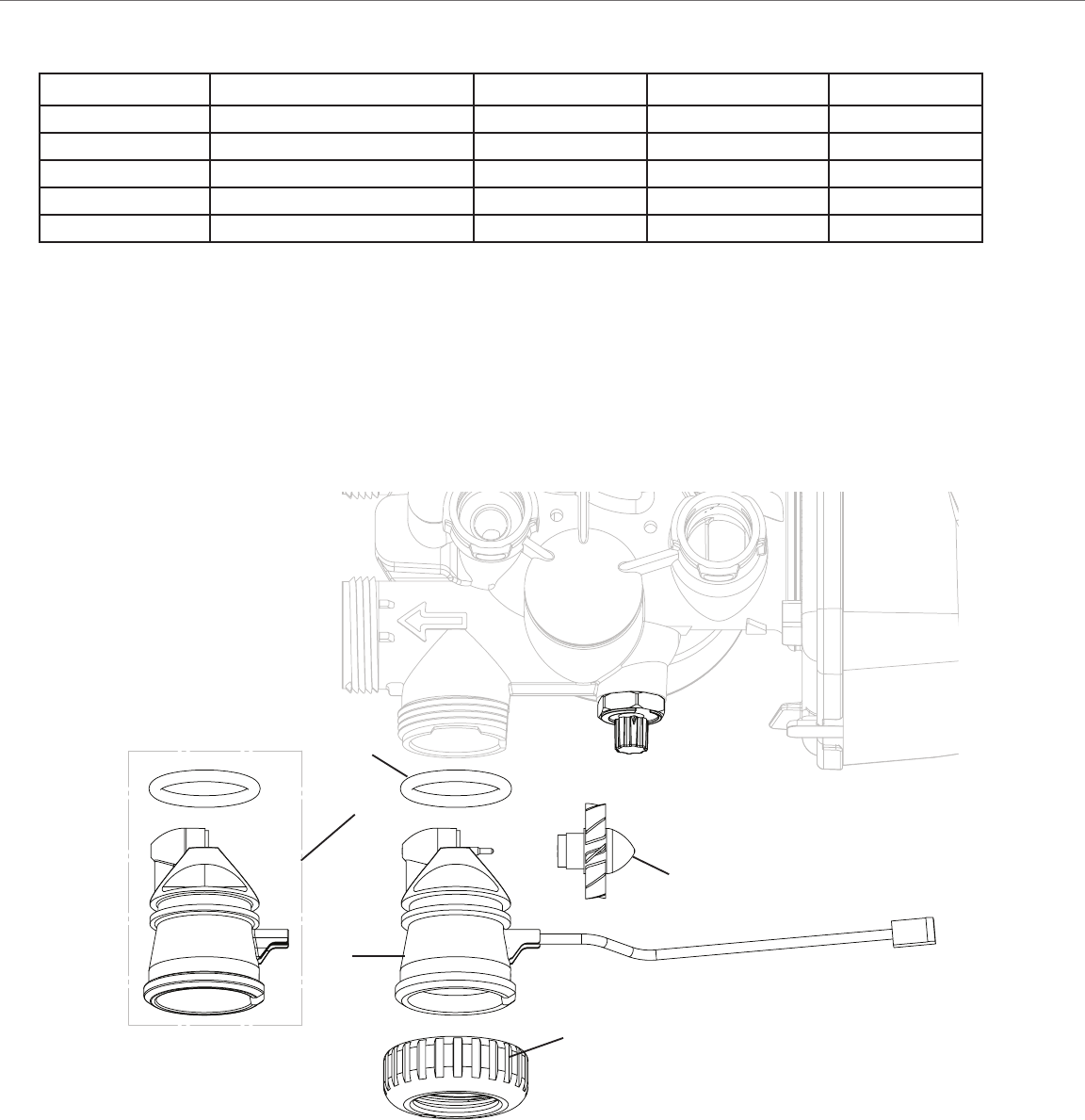

Drawing No. Part No. Mfg. Part No. Description Quantity

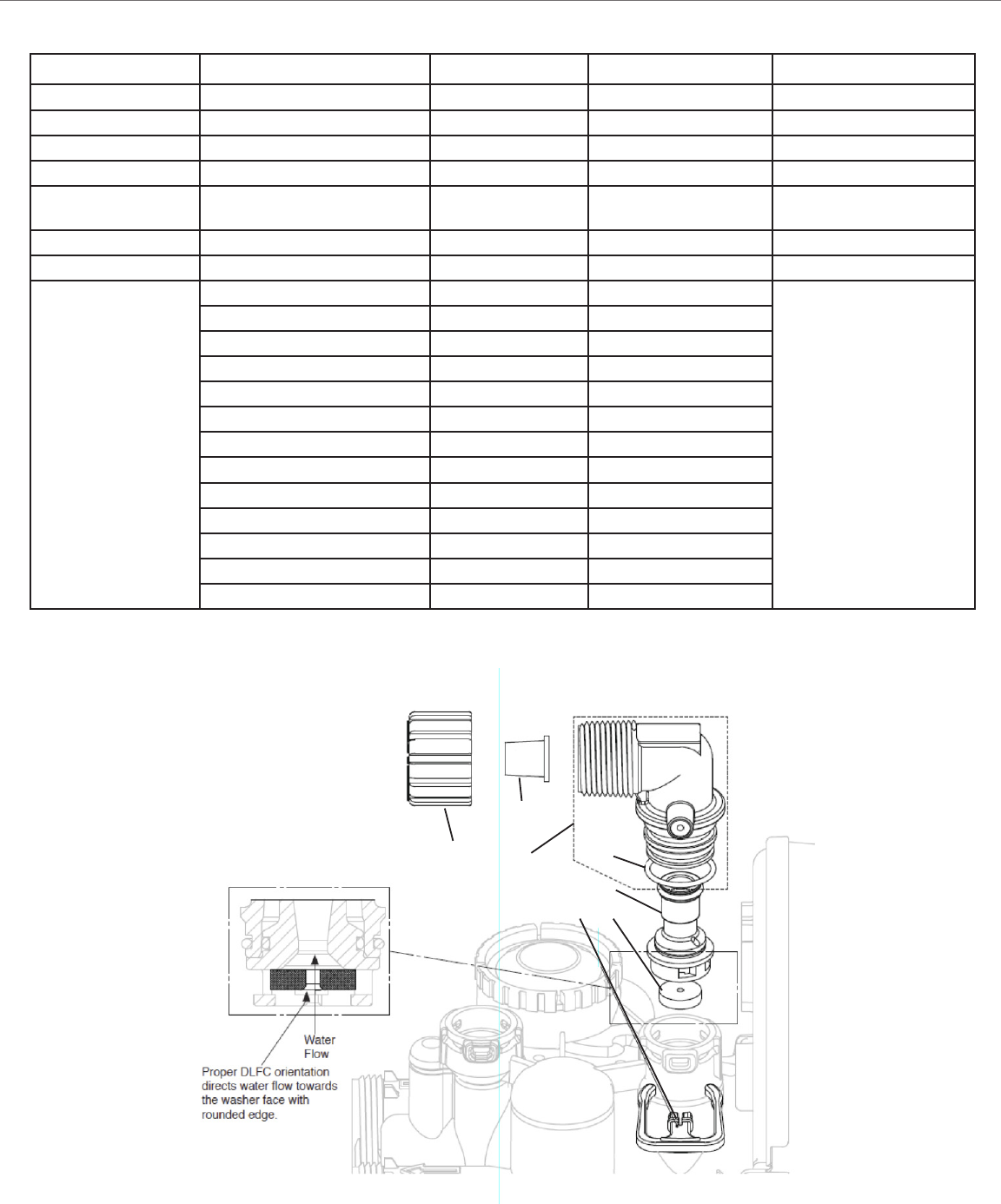

1 3CVREFILLPORTPLUGASY V3195-01 This part is required for back

2 3CVLOCKINGCLIPH4615 H4615 1

3 H4628 1

4 3CVELBOWORINGV3163 V3163 O-Ring 019 1

5 3CVRETAINERASYV3165 V3165-01* RFC Retainer Asy (0.5 gpm) *

6 V3182 1

7 V3330-01 1

** V3552 Option

** H4650 Option

Rell Flow Control Assembly and Rell Port Plug

Water

Flow

Proper RFC orientation

directs refi ll water fl ow

towards the washer face

with rounded edge and text.

Figure 31

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVREFILLPORTPLUGASY V3195-01 This part is required for back

2 3CVLOCKINGCLIPH4615 H4615 1

3 H4628 1

4 3CVELBOWORINGV3163 V3163 O-Ring 019 1

5 3CVRETAINERASYV3165 V3165-01* RFC Retainer Asy (0.5 gpm) *

6 V3182 1

7 V3330-01 1

** V3552 Option

** H4650 Option

7

3 1

4

5

6

2

42

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVLOCKINGCLIPH4615 H4615 1

2 PKP10TS8-Bulk Option

3 V3192 Option

4* V3158-01 1

4* 3CVDRAINELBOWNOSILEN V3158-02

Silencer

1

5 3CVELBOWORINGV3163 V3163 O-Ring 019 1

6* 3CVDLFCRETAINERASY V3159-01 DLFC Retainer Asy 1

7

V3162-007 DFLC 0.7 gpm for ¾

One DLFC must be used if

V3162-010 DFLC 1.0 gpm for ¾

V3162-013 DFLC 1.3 gpm for ¾

V3162-017 DFLC 1.7 gpm for ¾

3CVDLFC022 V3162-022 V3162-022 DFLC 2.2 gpm for ¾

3CVDLFC027 V3162-027 V3162-027 DFLC 2.7 gpm for ¾

3CVDLFC032 V3162-032 V3162-032 DFLC 3.2 gpm for ¾

3CVDLFC042 V3162-042 V3162-042 DFLC 4.2 gpm for ¾

3CVDLFC053 V3162-053 V3162-053 DFLC 5.3 gpm for ¾

3CVDLFC065 V3162-065 V3162-065 DFLC 6.5 gpm for ¾

3CVDLFC075 V3162-075 V3162-075 DFLC 7.5 gpm for ¾

3CVDLFC090 V3162-090 V3162-090 DFLC 9.0 gpm for ¾

3CVDLFC100 V3162-100 V3162-100 DFLC 10.0 gpm for ¾

Figure 32

3

2

4

5

7

6

1

Drain Line Flow Control Assembly

43

*Order number V3003 includes V3118-01 Turbine Asy and V3105 O-Ring 215.

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1”QC 1

2 3CVMETERASYV3003 V3003* Meter ASY 1

3 3CVTURBINEASYV311801 V3118-01 Turbine ASY 1

4 3CVBPFTG ORINGV3105 V3105 O-Ring 215 1

5 3CVMETERPLUG300301 V3003-01 Meter Plug ASY 1

Water Meter, Meter Plug, and Mixing Valve

Figure 33

5

4

2

1

3

44

OFF

OFF

OFF

OFF

Figure 34

1

2

3

4

5

6

7

8

9

10

Drawing No. Part No. Mfg. Part No. Description Quantity

3CVBYPASSV3006 V3006 Bypass Assembly 1

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) Quick Connect (QC) 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3145 Bypass 1" (2.54 cm) Rotor 2

5 V3146 Bypass Cap 2

6 V3147 Bypass Handle 2

7 V3148 Bypass Rotor Seal Retainer 2

8 3CVORINGINJBPV3152 V3152 O-Ring 135 2

9 V3155 O-Ring 112 2

10 V3156 O-Ring 214 2

Bypass Valve

45

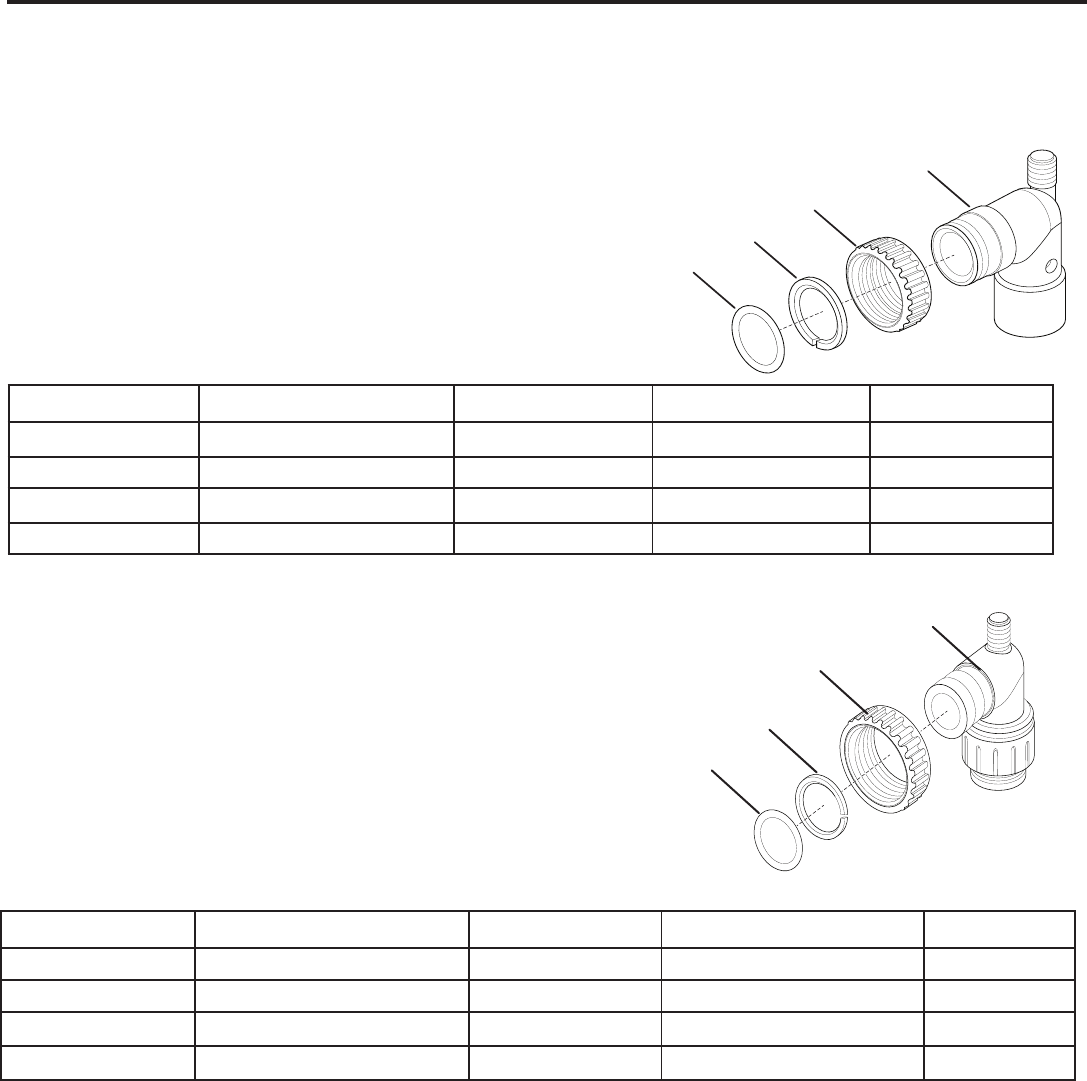

Figure 35

1

2

3

4

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3189 2

Order No.: 3CVBPFTGV3007-01

Description:

Figure 36

1

2

3

4

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3790 2

Order No.: 3CVBPFTGV3007-15

Description:

®

QC 90° Assembly

BYPASS FITTING PACKAGES

Bypass Fitting Packages

46

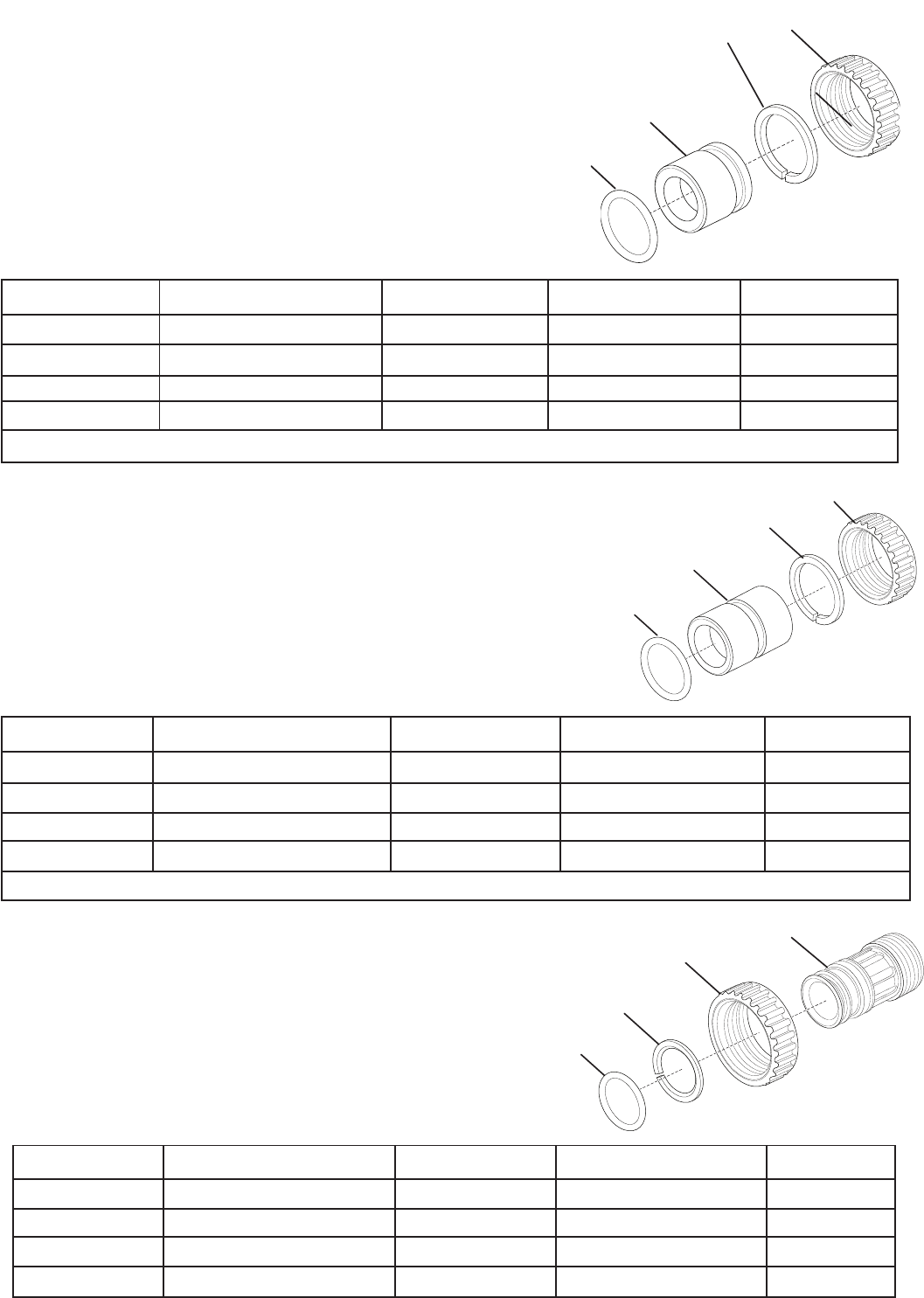

Order No.: 3CVBPFTGV3007-03

Description:

Figure 37

2

4

3

1

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3188-01LF 2

Do not install in California

Bypass Fitting Packages

Order No.: 3CVBPFTGV3007-02

Description:

Figure 38

2

4

3

1

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3188-LF 2

Do not install in California

Order No.: 3CVBPFTGV007-04

Description: Fitting 1” (2.54 cm) Male MPT Assembly

Figure 39

1

2

3

4

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3164 1" Male MPT 2

47

Bypass Fitting Packages

1

2

3

4

1

2

3

4

Figure 42

Figure 41

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3629-LF 1" Brass SharkBite

®

LF 2

Order No.: 3CVBPFTG1.0V3007-13

Description: Fitting 1” (2.54 cm) Brass SharkBite

®

Assembly LF

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3191 Bypass Vertical Adapter 2

Order No.: 3CVBPFTGV3191-01

Description: Fitting Bypass Vertical Adapter Assembly

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3628-LF

®

Assembly LF 2

Order No.: 3CVBPFTGV3007-12

Description:

®

Assembly LF

1

2

3

4

Figure 40

48

Order No.: 3CVBPFTGV3007-17

Description: Fitting 1” (2.54 cm) John Guest

®

QC Assembly

Figure 43

1

2

3

4

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V4045 1" John Guest

®

QC ASY 2

Bypass Fitting Packages

Figure 44

1

2

4

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V3149 2

Order No.: 3CVBPFTGV3007-00

Description:

Order No.: 3CVBPFTGV3007-18

Description:

1

2

3

4

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V4232 2

3

Figure 45

49

Drawing No. Part No. Mfg. Part No. Description Quantity

1

3CVBPFTG NUT1INV3151

V3151

Nut 1" (2.54 cm) QC

2

2

3CVBPFTG RINGV3150

V3150

Split Ring

2

3

3CVBPFTG ORINGV3105

V3105

O-Ring 215

2

4

V3149

2

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V4317 2

Order No.: 3CVBPFTGV3007-20

Description: Fitting 1" (2.54 cm) John Guest

®

Figure 47

1

2

3

4

1

2

3

4

Order No.: 3CVBPFTGV3007-19

Description:

®

Straight QC Assembly

Figure 46

Drawing No. Part No. Mfg. Part No. Description Quantity

1 3CVBPFTG NUT1INV3151 V3151 Nut 1" (2.54 cm) QC 2

2 3CVBPFTG RINGV3150 V3150 Split Ring 2

3 3CVBPFTG ORINGV3105 V3105 O-Ring 215 2

4 V4223 2

Bypass Fitting Packages

50

Problem Possible Cause Solution

No Display on PC Board 1.

2.

end not connected to PC board

connection

3.

4.

5. . Defective PC Board)

1.

2.

cord end to PC Board connection

3. Verify proper voltage is being delivered to PC

Board

4.

5. Replace PC Board

PC Board does not display

correct time of day

1.

2.

tripped GFI

3.

4. Defective PC Board

1. Use uninterrupted outlet

2.

3. Reset time of day. If PC Board has battery back

up present the battery may be depleted. Refer to

4. Replace PC Board

Display does not indicate that

1. Bypass valve in bypass position

2. Meter is not connected to meter

connection on PC Board

3.

4.

into three pin connector

5. Defective meter

6. Defective PC Board

1. Turn bypass handles to place bypass in service

position

2. Connect meter to three pin connection labeled

METER on PC board

3. Remove meter and check for rotation or foreign

material

4.

into three pin connector labeled METER

5. Replace meter

6. Replace PC Board

Control valve regenerates

1.

2. Time of day not set correctly

3. Time of regeneration set incorrectly

4. Control valve set at “on 0”

(immediate regeneration)

5. Control valve set at “NORMAL + on

1. Reset time of day. If PC Board has battery

back up present the battery may be depleted.

Refer to battery replacement for instructions.

2. Reset to correct time of day

3. Reset regeneration time

4. Check programming setting and reset to

NORMAL (for a delayed regen time)

5. Check programming setting and reset

to NORMAL (for a delayed regen time)

Reset time of day. If PC Board has battery

back up present the battery may be depleted.

Refer to battery replacement for instructions.

TROUBLESHOOTING

51

Problem Possible Cause Solution

Timer does not display correct

time of day

1.

2.

3. Defective PC board

1. Use uninterrupted outlet

2. Transformer unplugged

3. Replace PC board

Timer does not display time of day 1. Transformer unplugged

2.

3. Defective transformer

4. Defective PC board

1.

2.

3. Replace transformer

4. Replace PC board

Control valve does not regenerate

button (s) is depressed and held.

For TC valves the buttons are

button is REGEN

1. Broken drive gear or drive cap

assembly

2. Broken Piston Rod

3. Defective PC Board

1. Replace drive gear or drive cap

assembly

2. Replace piston rod

3. Defective PC Board

Control valve does not regenerate

correct button (s) is depressed and

held. For TC valves the buttons

are

button is REGEN

1. Bypass valve in bypass position

2. Meter is not connected to meter

connection on PC Board

3.

4. Incorrect programming

5.

three pin connector

6. Defective meter

7. Defective PC Board

1. Turn bypass handles to place bypass

in service position

2. Connect meter to three pin connection

labeled METER on PC Board

3. Remove meter and check for rotation

or foreign material

4. Check for programming error

5.

securely into three pin connector

labeled METER

6. Replace meter

7. Replace PC Board

delivered

1. Bypass valve is open or faulty

2. Media is exhausted due to high

usage

3. Meter not registering

4.

5.-

erant

in regenerant tank

6.

7.

regenerant

tank

1. Fully close bypass valve or replace

2. Check program settings or diagnostics

3. Remove meter and check for

rotation or foreign material

4.

accordingly

5. Add proper regenerant to tank

6. Refer to Trouble Shooting Guide

7.

or debris and clean or replace

52

Problem Possible Cause Solution

Control valve uses too much

regenerant

1.

2. Improper program settings

3. Control valve regenerates frequently

1.

2. Check program setting to make sure

and application needs

3.

exhausting capacity or system is

undersized

Residual regenerant being

delivered to service

1.

2. Incorrect injector size

3. Restricted drain line

1.

minimum of 25 psi

2.

the application

3. Check drain line for restrictions or

debris and clean

1. Improper program settings

2. Plugged injector

3. Drive cap assembly not tightened in

properly

4.

5. Restricted or kinked drain line

6.

7.

1.

2. Remove injector and clean or replace

3. Re-tighten the drive cap assembly

4.

5. Check drain line for restrictions or

debris and or un-kink drain line

6.

clean or replace

7.

1. Injector is plugged

2. Faulty regenerant piston

3. Regenerant line connection leak

4. Drain line restriction of debris cause

excess back pressure

5. Drain line too long or too high

6.

1. Remove injector and clean or replace

2. Replace regenerant piston

3. Inspect regenerant line for air leak

4. Inspect drain line and clean to correct

restriction

5. Shorten length and or height

6.

pressure must remain at minimum of

20 psi (1.38 bar)

Water running to drain 1.

2.

3. Piston assembly failure

4. Drive cap assembly not tightened

in properly

1.

Reset time of day.

2.

3. Replace piston assembly

4. Re-tighten the drive cap assembly

53

Problem Possible Cause Solution

Err – 101 = Control unable to

sense motor movement

1. Motor not inserted full to engage pinion,

2. PC Board not properly snapped into drive

bracket

3. Missing reduction gears

1.

is fully engaged, check for broken

connection on the PC Board labeled

MOTOR. Press NEXT and REGEN

buttons for 3 seconds to

from PC Board for 5 seconds and

then reconnect

2. Properly snap PC Board into drive

bracket and then Press NEXT and

REGEN buttons for 3 seconds to

from PC Board for 5 seconds and

then reconnect

3. Replace missing gears

Err – 102 = Control valve motor ran

the next cycle position and stalled

1. Foreign material is lodged in control valve

2. Mechanical binding

3. Main drive gear too tight

4. Improper voltage being delivered to

PC Board

1. Open up control valve and pull out

assembly for inspection. Press NEXT

and REGEN buttons for 3 seconds to

from PC Board for 5 seconds and

then reconnect

2.

assembly, check reduction gears,

check drive bracket and main drive

gear interface. Press NEXT and

REGEN buttons for 3 seconds to

from PC Board for 5 seconds and

then reconnect

3. Loosen main drive gear. Press NEXT

and REGEN buttons for 3 seconds to

from PC Board for 5 seconds and

then reconnect

4. Verify that proper voltage is being

supplied. Press NEXT and REGEN

buttons for 3 seconds to resynchro-

Board for 5 seconds and then

reconnect

54

Problem Possible Cause Solution

Err – 103 = Control

valve motor ran too long

next cycle position

1. Motor failure during a regeneration

2. Foreign matter built up on piston and

stack assemblies creating friction and

drag enough to time out motor

3. Drive bracket not snapped in properly

and out enough that reduction gears

and drive gear do not interface

1. Check motor connections then press NEXT and

REGEN buttons for 3 seconds to resynchronize

supply from PC board for 5 seconds and then

reconnect

2. Replace piston and stack assemblies. Press NEXT

and REGEN buttons for 3 seconds to resynchronize

supply from PC Board for 5 seconds and then

reconnect

3. Snap drive bracket in properly then press NEXT

and REGEN buttons for 3 seconds to resynchronize

supply from PC board for 5 seconds and then

reconnect

Err – 104 = Control valve

motor ran too long and

timed out trying to reach

home position

Drive bracket not snapped in properly

and out enough that reduction gears and

drive gear do not interface

Snap drive bracket in properly then press NEXT and

REGEN buttons for 3 seconds to resynchronize

supply from PC board for 5 seconds and then

reconnect

Err – 106, Err - 116 =

AUX MAV valve motor ran

the proper park position

Motorized Alternating

Valve = MAV

Separate Source =SEPS

No Hard Water Bypass =

NHBP

Auxiliary MAV = AUX MAV

1. Control valve programmed for ALT A

out having a MAV or NHBP valve

attached to operate that function

2.

to PC Board

3.

4. Foreign matter built up on piston and

stack assemblies creating friction and

drag enough to time out motor

1. Press NEXT and REGEN buttons for 3 seconds

seconds and then reconnect. Then re-program

valve to proper setting

2.

connection labeled DRIVE. Press NEXT and

REGEN buttons for 3 seconds to resynchronize

supply from PC Board for 5 seconds and then

reconnect

3. Properly insert motor into casing, do not force into

casing Press NEXT and REGEN buttons for 3

Board for 5 seconds and then reconnect

4. Replace piston and stack assemblies. Press

NEXT and REGEN buttons for 3 seconds to

seconds and then reconnect

valve motor ran too short

proper park position

Motorized Alternating

Valve = MAV

Separate Source = SEPS\

No Hard Water Bypass =

NHBP

Auxiliary MAV = AUX MAV

1.

NHBP valve

2. Mechanical binding

1.

NEXT and REGEN buttons for 3 seconds to

seconds and then reconnect

2.

reduction gears, drive gear interface, and check

jammed into motor body. Press NEXT and REGEN

from PC Board for 5 seconds and then reconnect

55

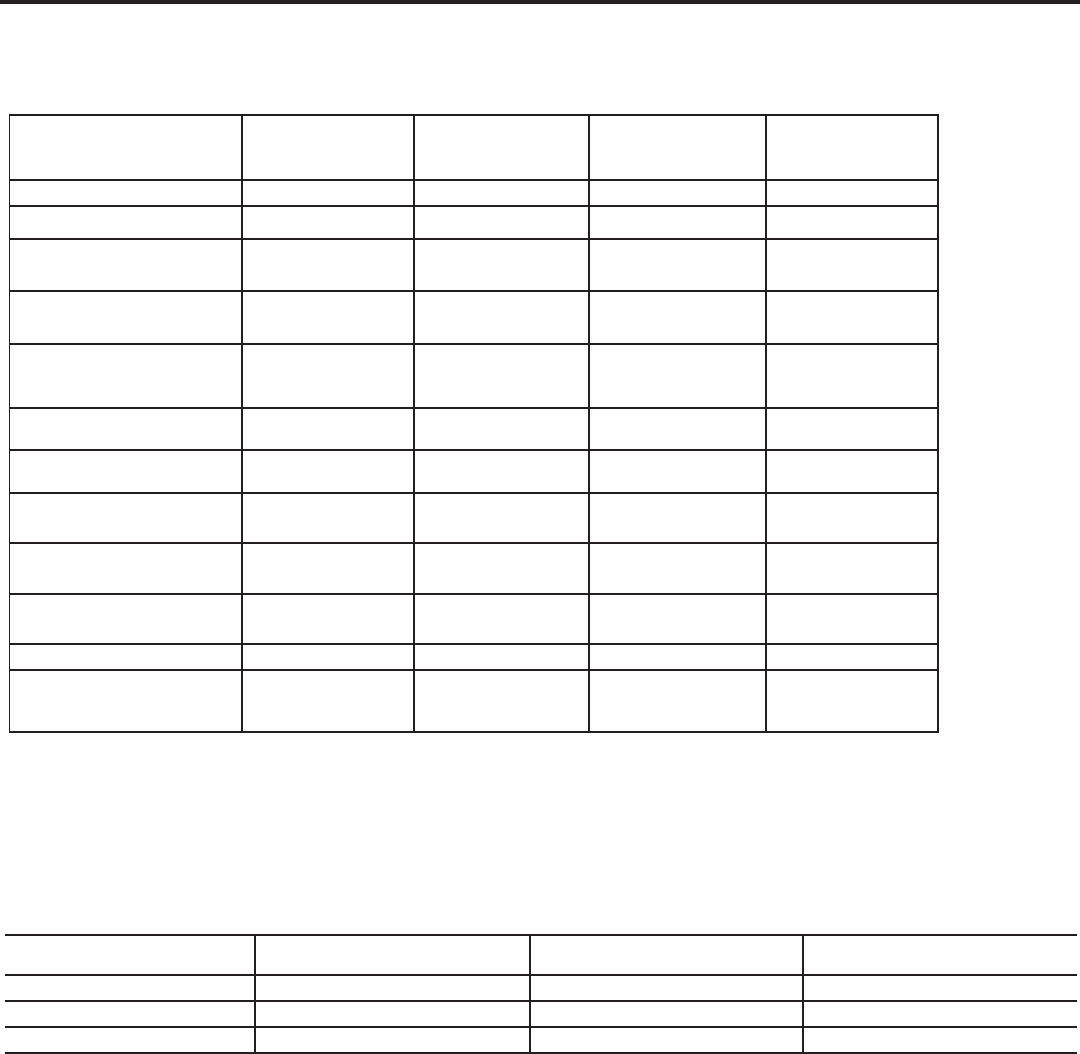

Error Code Description of Error

101 Valve Motor Output Energized - NOT SENSING VALVE MOVEMENT - perform soft reset to clear

102

to regen to be sure obstruction is clear

103

104 Valve Motor UNABLE TO FIND HOME POSITION - during regeneration or control reset - perform soft reset to clear

106

107

perform soft reset to clear

109

by the micro-controller - perform soft reset to clear

116

56

PERFORMANCE DATA SHEET

Model Numbers

*

***

3M-ST32-XXX

*

***

3M-ST40-XXX

*

****

3M-ST48-XXX

*

***

3M-ST64-XXX

*

***

3M-ST80-XXX

9.0 gpm 10.0 gpm 13.0 gpm 15.0 gpm 15.0 gpm

8 psi 9 psi 15 psi 15 psi 15 psi

15.9 gpm @ 15 psi

18.2 gpm @ 20 psi

22.4 gpm @ 25 psi

16.2 gpm @15 psi

19.2 gpm @ 20 psi

22.0 gpm @ 25 psi

17.7 gpm @ 15 psi

21.1 gpm @ 20 psi

24.0 gpm @ 25 psi

20.0 gpm @ 15 psi

23.5 gpm @ 20 psi

26.6 gpm @ 25 psi

14.5 gpm @ 15 psi

17.3 gpm @ 20 psi

19.8 gpm @ 25 psi

Electrical Requirements

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

23,500 @ Std (9.0lbs)

28,000 @ High (15.0lbs)

29,375 @ Std (11.3lbs)

35,500 @ High (18.8lbs)

35,250 @ Std (13.5lbs)

42,000 @ High (22.5lbs)

48,000 @ Std (18.0lbs)

56,000 @ High (30.0lbs)

58,750 @ Std (22.5lbs)

70,000 @ High (37.5lbs)

Type and amount of Ion Exchange

resin

Premium Cation

1.0 cu ft

Premium Cation

1.25 cu ft

Premium Cation

1.5 cu ft

Premium Cation

2.0 cu ft

Premium Cation

2.5 cu ft

Working Water Pressure

20 to 120 psi

20 to 120 psi

20 to 120 psi

20 to 120 psi

20 to 120 psi

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

to drain during regeneration

salt setting

18,200 grains 22,750 grains 27,300 grains 36,400 grains 45,500 grains

Accepted type or grade, pellet or

Sodium Chloride Sodium Chloride Sodium Chloride Sodium Chloride Sodium Chloride

International Plumbing Code (IPC) and International Residential Code (IRC).

Substance Reduction Requirement Average% Reduction

Chlorine >50% reduction 89.9%

Barium

exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchanged per kilogram of

standard laboratory conditions, actual performance can vary.

Refer to the system installation and operations manual for set-up and programming instructions.

operations manual for user responsibility, parts and service availability, any further restrictions or limitations to the

use of this product.

MAYTAG

®

WATER TREATMENT SYSTEM

57

PERFORMANCE DATA SHEET

Model Numbers

*

***

3M-ST32-XXX

*

***

3M-ST40-XXX

*

****

3M-ST48-XXX

*

***

3M-ST64-XXX

*

***

3M-ST80-XXX

9.0 gpm

10.0 gpm

13.0 gpm

15.0 gpm

15.0 gpm

8 psi

9 psi

15 psi

15 psi

15 psi

15.9 gpm @ 15 psi

18.2 gpm @ 20 psi

22.4 gpm @ 25 psi

16.2 gpm @15 psi

19.2 gpm @ 20 psi

22.0 gpm @ 25 psi

17.7 gpm @ 15 psi

21.1 gpm @ 20 psi

24.0 gpm @ 25 psi

20.0 gpm @ 15 psi

23.5 gpm @ 20 psi

26.6 gpm @ 25 psi

14.5 gpm @ 15 psi

17.3 gpm @ 20 psi

19.8 gpm @ 25 psi

Electrical Requirements

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

23,500 @ Std (9.0lbs)

28,000 @ High (15.0lbs)

29,375 @ Std (11.3lbs)

35,500 @ High (18.8lbs)

35,250 @ Std (13.5lbs)

42,000 @ High (22.5lbs)

48,000 @ Std (18.0lbs)

56,000 @ High (30.0lbs)

58,750 @ Std (22.5lbs)

70,000 @ High (37.5lbs)

Type and amount of Ion Exchange

resin

Premium Cation

1.0 cu ft

Premium Cation

1.25 cu ft

Premium Cation

1.5 cu ft

Premium Cation

2.0 cu ft

Premium Cation

2.5 cu ft

Working Water Pressure

20 to 120 psi

20 to 120 psi

20 to 120 psi

20 to 120 psi

20 to 120 psi

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

to drain during regeneration

salt setting

18,200 grains

22,750 grains

27,300 grains

36,400 grains

45,500 grains

Accepted type or grade, pellet or

Sodium Chloride

Sodium Chloride

Sodium Chloride

Sodium Chloride

Sodium Chloride

International Plumbing Code (IPC) and International Residential Code (IRC).

exchange per pound of salt (based on NaCl equivalency) (477 grams of total hardness exchanged per kilogram of

laboratory conditions, actual performance can vary.

Refer to the system installation and operations manual for set-up and programming instructions.

operations manual for user responsibility, parts and service availability, any further restrictions or limitations to the use

of this product.

MAYTAG

®

WATER TREATMENT SYSTEM

Substance Reduction Requirement Average% Reduction

Chlorine >50% reduction 89.9%

Barium

Model Numbers

*

**

***

3M-STR32-XXX

*

**

***

3M-STR32XC-XXX

*

**

***

3M-STR40-XXX

*

**

***

3M-STR64-XXX

9.0.0 gpm 10.0.0 gpm 10.0 gpm 15.0 gpm

8 psi 8 psi 9 psi 15 psi

15.9 gpm @ 15 psi

18.2 gpm @ 20 psi

22.4 gpm @ 25 psi

15.9 gpm @ 15 psi

18.2 gpm @ 20 psi

22.4 gpm @ 25 psi

15.5 gpm @15 psi

18.7 gpm @ 20 psi

21.7 gpm @ 25 psi

16.5 gpm @ 15 psi

19.8 gpm @ 20 psi

22.8 gpm @ 25 psi

Electrical Requirements

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

Input: 100V-120V ~

23,500 @ Std (9.0lbs)

28,000 @ High (15.0lbs)

23,500 @ Std (9.0lbs)

28,000 @ High (15.0lbs)

29,375 @ Std (11.3lbs)

35,500 @ High (18.8lbs)

48,000 @ Std (18.0lbs)

56,000 @ High (30.0lbs)

Type and amount of Ion Exchange

resin

Premium Cation

1.0 cu ft

Premium Cation

1.0 cu ft

Premium Cation

1.25 cu ft

Premium Cation

2.0 cu ft

Working Water Pressure

20 to 120 psi

20 to 120 psi

20 to 120 psi

20 to 120 psi

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

35 to 100°F

(1.7 to 37.8°C)

to drain during regeneration

salt setting

18,200 grains 18,200 grains 22,750 grains

36,400 grains

Accepted type or grade, pellet or

Sodium Chloride Sodium Chloride Sodium Chloride Sodium Chloride

58

Warranty

59

Notes

W11572554A

®