Streamlined production of genetically modified T cells with activation,

transduction and expansion in closed-system G-Rex bioreactors

CHRISTINE GAGLIARDI, MARIAM KHALIL & AARON E. FOSTER

Bellicum Pharmaceuticals, Houston, Texas, USA

Abstract

Background: Gas Permeable Rapid Expansion (G-Rex) bioreactors have been shown to efficiently expand immune cells

intended for therapeutic use, but do not address the complexity of the viral transduction step required for many engineered

T-cell products. Here we demonstrate a novel method for transduction of activated T cells with Vectofusin-1 reagent. Trans-

duction is accomplished in suspension, in G-Rex bioreactors. The simplified transduction step is integrated into a stream-

lined process that uses a single bioreactor with limited operator intervention. Methods: Peripheral blood mononuclear cells

(PBMCs) from healthy donors were thawed, washed and activated with soluble anti-CD3 and anti-CD28 antibodies either

in cell culture bags or in G-Rex bioreactors. Cells were cultured in TexMACS GMP medium with interleukin (IL)-7 and

IL-15 and transduced with RetroNectin in bags or Vectorfusin-1 in the G-Rex. Total viable cell number, fold expansion, via-

bility, transduction efficiency, phenotype and function were compared between the two processes. Results: The simplified

process uses a single vessel from activation through harvest and achieves 56% transduction with 29-fold expansion in

11 days. The cells generated in the simplified process do not differ from cells produced in the conventional bag-based process

functionally or phenotypically. Discussion: This study demonstrates that T cells can be transduced in suspension. Further,

the conventional method of generating engineered T cells in bags for clinical use can be streamlined to a much simpler, less-

expensive process without compromising the quality or function of the cell product.

Key Words: autologous, bioreactors, cell therapy, chimeric antigen receptor T cells

Introduction

Manufacturing autologous T-cell therapies can be a

complex process. Gene transfer by viral transduction

to generate chimeric antigen receptor (CAR) T cells,

for example, has commonly been performed by

transferring activated T cells to bags or plates coated

with RetroNectin (Takara Bio USA, Inc., Mountain

View, CA, USA). The coating step requires dilution,

transfer and incubation of the RetroNectin solution

with subsequent washing and viral incubation before

T cells are added. After transduction, cell suspen-

sions are washed and transferred to additional cul-

ture vessels. Several of these steps are often open,

labor-intensive and cumbersome.

Alternatively, transduction of T cells in suspen-

sion could simplify viral gene transfer and reduce

time, cost and risk of errors. Vectofusin-1 (Miltenyi

Biotec Inc., Auburn, CA, USA) is a synthetic pep-

tide that can enhance viral transduction when added

in solution with virus and cells [1]. Vectofusin-1

forms a-helical nanofibrils that associate with viral

particles that enhance virus-cell interactions [2].

Transduction in solution with Vectofusin-1 elimi-

nates the need for surface coatings, expanding the

potential vessels in which T cells might be trans-

duced.

Gas Permeable Rapid Expansion (G-Rex; Wilson

Wolf Corporation, Saint Paul, MN, USA) bioreac-

tors are disposable single-use vessels specifically engi-

neered to culture and expand immune cells. Like

gas-permeable bags, G-Rex vessels are dependent on

incubation in standard cell culture incubators. G-

Rex technology relies on a silicone gas-permeable

membrane on which cells reside and through which

oxygen and carbon dioxide can be passively, effi-

ciently exchanged [3,4].

The G-Rex has been shown to be effective in

expanding tumor-infiltrating lymphocytes (TILs)

[5,6], natural killer (NK) cells [79],Vg9Vd2 T cells

[10], regulatory T cells [11] and virus-specific T cells

(VSTs) [1215]. In the context of genetically modi-

fied cells, such as CAR T cells, G-Rex bioreactors do

Corres ponde nce: Christine Gagliardi, PhD, Bellicum Pharmaceuticals, 2130 W. Holcombe Blvd Suite 800, Houston, Texas, USA. E-mail: [email protected]

(Received 18 April 2019; accepted 16 October 2019)

ISSN 1465-3249 Copyright © 2019 International Society for Cell and Gene Therapy. Published by Elsevier Inc. All rights reserved.

https://doi.org/10.1016/j.jcyt.2019.10.006

Cytotherapy, 2019; 21: 12461257

not directly address the added complexity of gene

transfer, however, viral transduction in solution with

Vectofusin-1 may allow for an integrated process in

which all unit operations are carried out in a single

G-Rex bioreactor.

The objective of this study was to simplify and

optimize the transduction and expansion steps of

manufacturing genetically modified T cells for clini-

cal use. We demonstrate a streamlined, novel

method for transducing T cells with retrovirus

directly in a G-Rex bioreactor using the Vectofusin-1

reagent, followed by robust expansion with no need

for operator intervention until harvest.

Materials and Methods

Starting material

Buffy coats from healthy donors were purchased

through the Gulf Coast Regional Blood Center

(Houston, TX, USA). Peripheral blood mononu-

clear cells (PBMCs) were isolated from buffy coat

using density gradient centrifugation with Lympho-

prep medium (STEMCELL Technologies Inc.,

Cambridge, MA, USA) per the manufacturer’s pro-

tocol. PBMCs were cryopreserved at 5 £ 10

7

cells/

mL in fetal bovine serum with 10% dimethyl sulfox-

ide and stored in liquid nitrogen until needed.

Culture imitation and T-cell activation

Cryopreserved PBMCs were thawed and washed in

cell culture medium. Small-scale experiments aimed

at understanding growth kinetics on the G-Rex

membrane were cultured and activated in a 50:50

mix of Gibco RPMI 1640 medium (Thermo Fisher

Waltham, MA, USA) and Clicks Medium EHAA

(FUJIFILM Irvine Scientific, Santa Ana, CA, USA)

with 10% fetal bovine serum. For transduction and

large-scale experiments, TexMACS GMP medium

(Miltenyi Biotec) was used.

Cells were counted and resuspended at

12 £ 10

6

cells/mL in medium with 15 ng/mL inter-

leukin (IL)-7, 5 ng/mL IL-15, 0.2 mg/mL anti-CD3

antibody and 0.5 mg/mL anti-CD28 antibody.

Cytokines and antibodies were from Miltenyi Biotec.

Cell suspension was transferred to VueLife “C” bags

(Saint-Gobain Cell Therapy, Gaithersburg, MD,

USA) and incubated at 37˚C, 5% CO

2

for 2 days.

For activation in G-Rex 6M 10 cm

2

plates (Wil-

son Wolf Corporation), PBMCs were thawed,

washed and counted. Aliquots of 1 £ 10

7

viable cells

were resuspended in 2.0, 4.0 or 10.0 mL medium

with 15 ng/mL IL-7, 5 ng/mL IL-15, 0.2 mg/mL

anti-CD3 antibody and 0.5 m g/mL anti-CD28 anti-

body. The cell suspensions were transferred to

individual 10-cm

2

wells and incubated at 37˚C, 5%

CO

2

for 2 days.

Transduction

Two high-titer retroviral constructs were used for

this study. One virus, used in the small-scale experi-

ments, carries a rapamycin-induced, caspase-9 safety

switch (iRC9) with a truncated CD19 marker that

was designed to work in combination with rimidu-

cid-controlled elements [16]. The other, used in the

large-scale process, carries a first generation prostate

stem cell antigen (PSCA) CAR with rimiducid-

inducible co-stimulation (inducible MyD88/CD40

[iMC]) and a CD34 epitope that can be used to mea-

sure transduction efficiency [1719].

For transduction in bags, 20 mg/mL RetroNectin

(Takara) in phosphate-buffered saline was incubated

in VueLife “AC” bags (Saint-Gobain) overnight at

4˚C. The RetroNectin solution was removed and

viral supernatant diluted in cell culture medium was

incubated in the bag for at least 30 min at room tem-

perature. Activated T cells were washed, resus-

pended in culture medium with 15 ng/mL IL-7 and

5 ng/mL IL-15 and added to the viral supernatant in

the bag. Bags were incubated at 37˚C, 5% CO

2

for 1

h, then flipped and incubated for 1824 h. After

incubation, cell suspensions were washed in cell cul-

ture medium, resuspended at 0.51.0 £ 10

6

cells/

mL in medium with 15 ng/mL IL-7 and 5 ng/mL IL-

15, transferred to VueLife “C” bags and incubated at

37˚C, 5% CO

2

.

For transduction in G-Rex bioreactors, Vectofu-

sin-1 (Miltenyi Biotec) was diluted to 1 mg/mL in

sterile water. Vectofusin-1 (10 mg/mL final concen-

tration) was combined with retroviral supernatant at

multiplicity of infection (MOI) 130. The solution

was added to activated T cells in the G-Rex and incu-

bated at 37˚C, 5% CO

2

for 1824 h. After incuba-

tion, cell culture medium with IL-7 and IL-15 was

added to the maximum volume of the vessel (10 mL/

cm

2

) and placed back in the incubator.

Expansion

For expansion in bags, samples were taken daily to

measure glucose and lactate concentrations, viable

cell density and viability. Cell suspensions were

diluted to 0.51.0 £ 10

6

cells/mL with fresh medium

when the cell density exceeded 2 £ 10

6

cells/mL.

For expansion in G-Rex bioreactors, samples

were taken daily to measure glucose and lactate con-

centrations. If sampled for count and viability, 90%

of medium was removed, cells were pipetted into sus-

pension, volume was measured and a sample was

Streamline production of genetically modified T cells 1247

taken. Fresh medium with cytokines was added to

the maximum volume.

In-process monitoring

Glucose concentration was measured with a CVS

Health Advanced Blood Glucose Meter (CVS

Health, Woonsocket, RI, USA). Lactate concentra-

tion was measured with the Lactate Plus Meter

(Nova Biomedical, Waltham, MA, USA). Cell count

and viability were measured on the Nucleocounter

NC-3000 (Chemometec, Allerod, Denmark).

Flow cytometry

Flow cytometry was performed on a Novocyte 3000

(ACEA Biosciences, Inc., San Diego, CA, USA) and

analyzed with ACEA NovoExpress software. Cells

were analyzed for transgene expression, CD4:CD8

ratio and memory population distribution. The follow-

ing antibodies were used in the flow panel: CD34-PE

(ABNova, Walnut, CA, USA) or CD19-PE for trans-

gene detection, CD4-PerCP, CD45RA-PE Cy7 (BD

Biosciences, San Jose, CA, USA), CD62L-APC,

CD3-Alexa Fluor 700 and CD8-BV510. Unless noted,

antibodies were from BioLegend. Zombie yellow fix-

able viability dye (BioLegend, San Diego, CA, USA)

was used to remove dead cells from the analysis. BD

Biosciences, San Jose, CA, USA.

Apoptosis assay

Cells from small-scale experiments were incubated

for 4 h with or without 10 nmol/L temsirolimus to

test function of the iCasp-9 transgene. After incuba-

tion, cells were stained with Annexin V-FITC,

CD19-PE, CD3-BV421 and zombie yellow fixable

viability dye in Annexin V binding buffer. All

reagents were from BioLegend. CD3

+

CD19

+

cells

were plotted on Annexin V against viability dye

graphs to show viable cells (Annexin V

/viability

dye

), apoptotic cells (Annexin V

+

/viability dye

)

and non-viable cells (Annexin V

+

/viability dye

+

).

Cytokine secretion assay

Cryopreserved aliquots of cells generated in the G-

Rex and bag large-scale processes were thawed,

washed and counted. Cells were resuspended at

2 £ 10

6

viable cells/mL in culture medium with IL-7

and IL-15 and incubated at 37˚C with 5% CO

2

over-

night. On the same day, 1 £ 10

4

PSCA

+

human pan-

creatic cancer cells (ATCC, Manassas, VA, USA)

were seeded per well of a 96-well plate and placed in

the incubator. The next day, T cells were harvested,

washed, counted and resuspended in medium at

2 £ 10

6

cells/mL. Then, 1 £ 10

4

T cells were plated

in each well of the 96-well plate containing the

PSCA

+

cells for an effector to target ratio of 1:1.

Each sample was tested with and without 10 nmol/L

rimiducid, which triggers the co-stimulation. After

48-h incubation, 25 mL supernatant was collected

for cytokine analysis with the Human Cytokine/Che-

mokine Magnetic Bead kit (Millipore) according to

the manufacturer’s instructions.

Closed-system process

For the good manufacturing practice (GMP)-com-

patible G-Rex (100 cm

2

) closed-system process,

PBMCs were thawed and activated in the G-

Rex100MCS in 40 mL (0.4 mL/cm

2

) on day 0. On

day 2, transduction reagents, including viral superna-

tant (MOI 5) and Vectofusin-1, were added. On day

3, medium was added to the maximum volume of

the vessel (1 L, 10 mL/cm

2

). Samples of the superna-

tant were taken daily for glucose and lactate concen-

tration measurement through the sampling port.

Cells were harvested on day 11 with the GatheRex

device (Wilson Wolf Corporation). A parallel bag-

based process was run for comparison. Briefly,

PBMCs from the same donors were thawed and acti-

vated in bags, followed by transduction at MOI 5 in

RetroNectin-coated bags on day 2. Cells were

washed and transferred to cell culture bags for

expansion. Samples were taken to measure viable

cell density and determine when cultures required

dilution. Total viable cells (TVCs), total transgene

Figure 1. Bag and G-Rexbased process overview.

1248 C. Gagliardi et al.

positive cells, percent transgenic cells, fold expan-

sion, phenotype and cytokine secretion were com-

pared between processes. Process flow charts are

shown in Figure 1.

Statistics

Statistics were calculated in GraphPad Prism. Version

7.03. Data are presented as mean § standard error of

the mean. Unpaired Student’s t-test was used to com-

pared differences between groups. One-way analysis

of variance was used compare multiple groups.

Results

Evaluation of T-cell expansion in G-Rex bioreactors

To observe kinetics of expansion in the G-Rex, 1 day

after bag transduction, T-cell cultures were washed,

resuspended in fresh medium and seeded in 10 cm

2

G-Rex 6-well plates at 0.031.00 £ 10

6

cells/cm

2

(i.e., 0.310.0 £ 10

6

cells/well). Then, 1 £ 10

7

cells

were cultured in a bag for comparison. Cells were

maintained in culture up to 3 weeks with count and

viability measurement and medium exchange every

34 days. In all conditions, cell proliferation pla-

teaued at 1014 days before expansion and viability

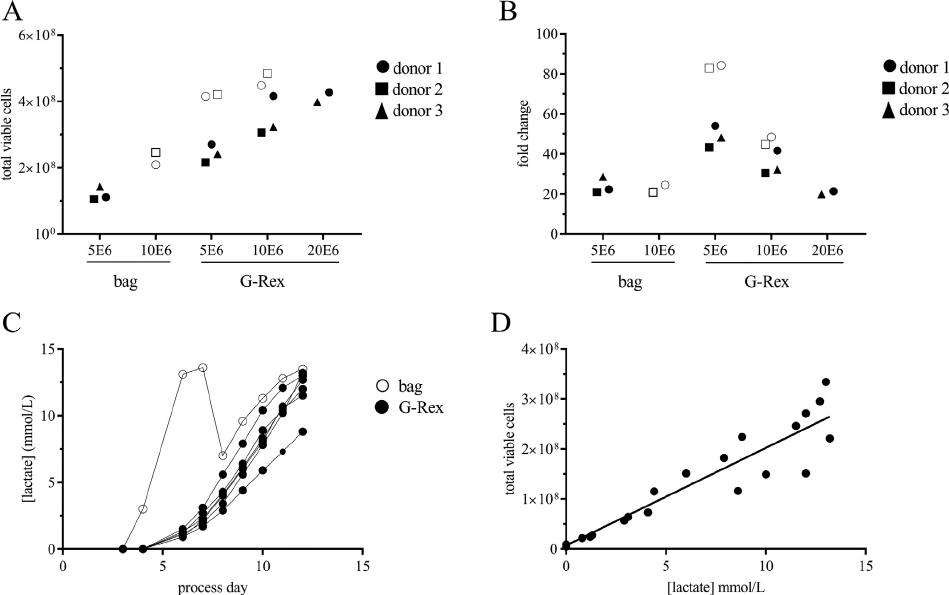

decreased (Figure 2). Lower seeding densities

allowed for higher fold expansion, whereas higher

densities resulted in more total viable cells. The max-

imum number of cells in one well (seeded at 1 £ 10

6

cells/cm

2

) peaked at 2.5 £ 10

8

total cells, or

2.5 £ 10

7

cells/cm

2

, which corresponds to 25-fold

expansion. Cells from the same donor, seeded a

lower density (0.06 £ 10

6

cells/cm

2

), expanded up to

42-fold to 2.6 £ 10

7

total cells. There was no differ-

ence it total cells at any timepoint between condi-

tions starting with 1 £ 10

7

in bags or G-Rex.

To determine the maximum density of the G-Rex

membrane, transduced T cells were plated at

0.52.0 £ 10

6

cells/cm

2

(i.e., 520 £ 10

6

cells/10

cm

2

well). G-Rex plates with maximum medium vol-

umes of 4 mL/cm

2

and 10 mL/cm

2

were tested to

determine if there is any benefit of the increased

medium height. Daily samples of supernatant were

taken for glucose monitoring, but the cell layers were

left undisturbed until harvest. To monitor prolifera-

tion, triplicate wells were harvested 3, 6 or 9 days

after seeding. Cytokines were added every 3 days to

replicate the environment in cell culture bags where

fresh medium is added as cell density is diluted. Cell

density at harvest was higher for cells cultured in the

6M format (10 mL/cm

2

medium; Figure 3). A

5 £ 10

5

cells/cm

2

seeding density resulted in harvest

density of 2.5 £ 10

7

cells/cm

2

(2.5 £ 10

8

TVCs on

10 cm

2

) in the smaller G-Rex compared with

4.2 £ 10

7

cells/cm

2

(4.2 £ 10

8

TVCs) in the 6M

G-Rex. There was little difference in harvest among

Figure 2. Kinetics of transduced T-cell proliferation, sampling to count every 34 days. Total viable cells (A, B) and fold expansion (C, D)

for 2 donors (A, C and B, D) grown in bags or 10 cm

2

G-Rex wells seeded with 0.310.0 £ 10

6

cells/well (0.03 1.0 £ 10

6

cells/cm

2

). Total

viable cells or fold change from day of seeding (y-axis) are plotted against process day (x-axis). Open circles represent data from bags; closed

circles represent data from G-Rex wells. Marker color is shaded according to seeding density. All conditions were resuspended and counted

every 34 days.

Streamline production of genetically modified T cells 1249

seeding 5 £ 10

5

or 1 £ 10

6

cells/cm

2

(42 § 0.3 £ 10

6

and 47 § 1.8 £ 10

6

TVCs) in the 6M plates and

2.0 £ 10

6

(41 § 1.5 £ 10

6

cells/cm

2

) in the smaller

plates (Figure 3).

To further optimize and simplify culture in the G-

Rex, the cytokine feeding schedule was evaluated.

The standard condition was supplementing cultures

with 15 ng/mL IL-7 and 5 ng/mL IL-15 every

3 days. Additional schedules were 45 ng/mL IL-7

and 15 ng/mL IL-15 given on the day of seeding

(i.e., 3x concentration once), 30 ng/mL IL-7 and

10 ng/mL IL-15 given on the day of seeding (i.e., 2x

concentration once) and 15 ng/mL IL-7 and

5 ng/mL IL-15 on the day of seeding and 5 days later

(i.e., 1x concentration twice in 9 days). There was no

difference in TVCs or viability in cultures given 3x

the usual amount of cytokines (45 ng/mL IL-7 and

15 ng/mL IL-15) on the day of seeding compared

with giving the standard concentration three times

over the course of expansion. Data from the same

experiments revealed a strong correlation between

lactate concentration in the G-Rex and the TVC

number (Figure 3).

Optimization of transduction in G-Rex bioreactors

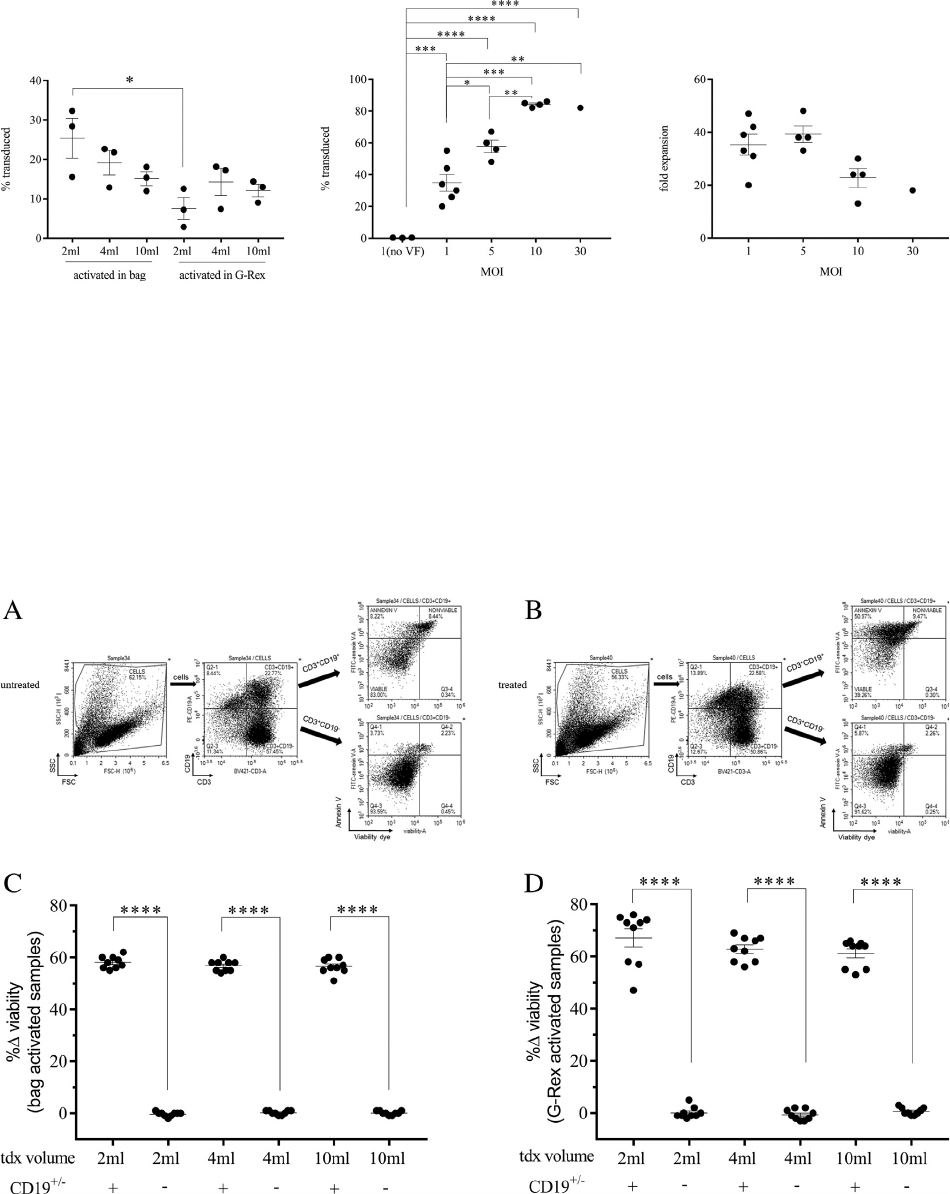

PBMCs activated in bags were washed and transduced

with an MOI of 1 in 2.0, 4.0, or 10.0 mL in 10 cm

2

G-

Rex 6M plates (i.e., 0.2 mL/cm

2

,0.4mL/cm

2

or 1.0 mL/

cm

2

). Transductions were successful at all volumes, rang-

ing from 25 § 5% at 0.2 mL/cm

2

to 15 § 2% at 1.0 mL/

cm

2

(Figur e 4A). At 0.4 mL/cm

2

, transduction efficiency

increases with increased MOI. A MOI of 1, 5, 10 and 30

resulted in transduction efficiencies of 35 § 5%, 58 §

4%, 84 § 1% and 82%, respectively (Figure 4B). Expan-

sion of transduced T cells was negatively impacted by

high MOI (Figure 4C). The average fold expansion of

samples transduced with MOI of 1 and 5 was 37 § 3-

fold compared with 21 § 3-fold at MOIs of 10 and 30.

PBMCs were also activated directly in G-Rex

bioreactors before transduction. To maintain a low

volume for transduction without having to wash or

remove supernatant, cells were activated in 2.0, 4.0

or 10 mL in 10 cm

2

G-Rex 6M plates (i.e., 0.2 mL/

cm

2

, 0.4 mL/cm

2

or 1.0 mL/cm

2

). On the day of

transduction, Vectofusin-1 was mixed with retrovirus

(MOI 1), and then added to the activated cells.

Figure 3. G-Rex maximum supported cell density and lactate accumulation. Total viable cells (A) and fold change (B) of transduced T cells

expanded in bags or G-Rex starting with 5 £ 10

6

,1£ 10

7

or 2 £ 10

7

cells. Black markers represent experiments with 4 mL/cm

2

G-Rex

plates; white markers represent experiments with 10 mL/cm

2

G-Rex 6M plates. (C) Sample plot from 1 experiment of lactate concentration

(y-axis) plotted against process day (x-axis) for 7 individual culture conditions. Open markers represent bag culture; closed markers repre-

sent G-Rex 6M culture. (D) Total viable cells (y-axis) plotted against lactate concentration (y-axis). Data points collected from multiple

donors and experiments. Solid line represents linear regression calculated in GraphPad; R

2

= 0.9081.

1250 C. Gagliardi et al.

Overall, transduction efficiency was lower than com-

parable conditions transduced after bag activation

and culture wash (Figure 4A). Nonetheless, 14 §

3% transduction was achieved after activation in 0.4

mL/cm

2

. Transgenic cells, expressing an inducible

caspase-9, generated by both methods and

transduced in the G-Rex were functionally active

and responded as expected when incubated with

temsirolimus to induce apoptosis (Figure 5). Via-

bility of cells expressing the transgene was reduced

60% with treatment, whereas viability did not

change in the non-transduced population.

Figure 4. Evaluation of transduction volume and MOI in 10 cm

2

G-Rex. (A) Percentage of transduced cells plotted against mL medium/

cm

2

for cells activated in bags or G-Rex before transduction in G-Rex. (B) Percentage of transduced cells plotted against MOI for cells acti-

vated in bags and transduced in G-Rex. No VF represents conditions incubated with MOI 1, but without Vectofusin-1 reagent. (C) Fold

expansion plotted against MOI. *P 0.05, **P 0.01, ***P 0.001, ****P 0.0001.

Figure 5. Transgene function after transduction in 10 cm

2

G-Rex. Example flow plots from one sample of untreated cells (A) or cells incu-

bated for 4 h with drug to induce apoptosis (B). The inducible caspase transgene is detected with the CD19 marker. Change in viability for

transduced (CD19

+

) and non-transduced (CD19

) fractions plotted against treatment group for cells activated in bags (C) or in G-Rex (D)

and then transduced in the G-Rex. Change in viability is calculated by the formula (untreated viability treated viability)/untreated viabil-

ity. ****P 0.0001.

Streamline production of genetically modified T cells 1251

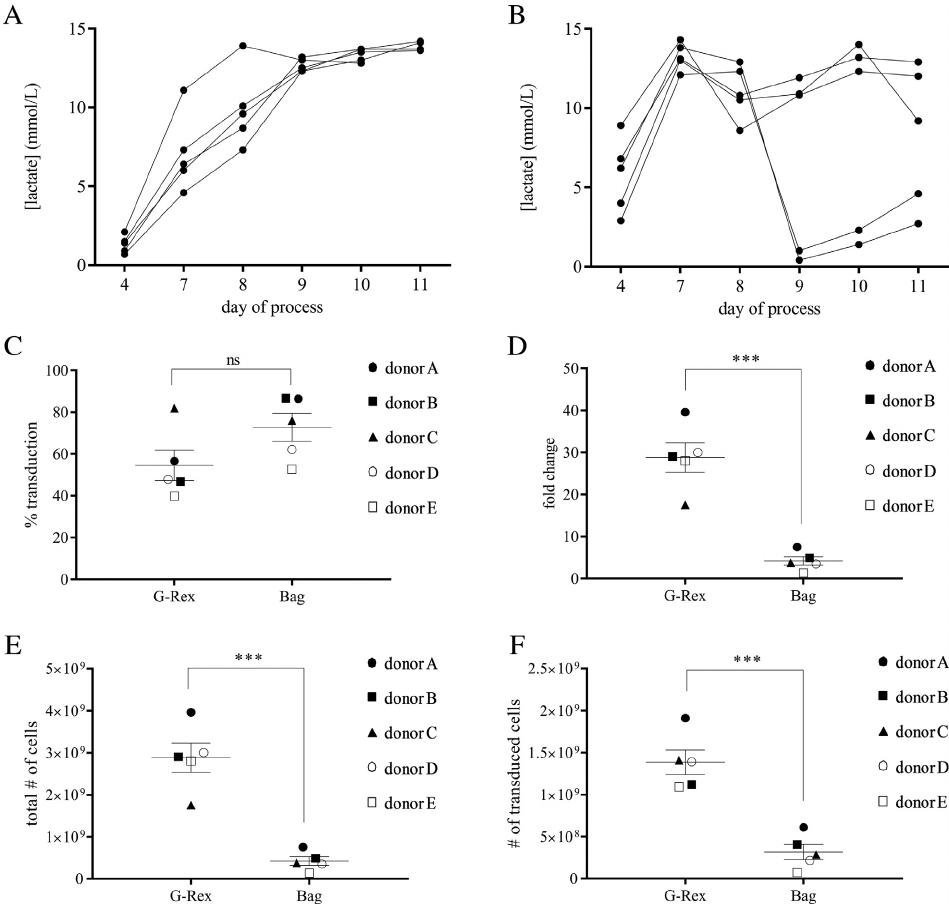

Closed-system G-Rexbased process

In-process monitoring of lactate buildup was used as

a surrogate marker of cell proliferation in the G-Rex.

There was a slow accumulation of lactate over time

in the G-Rex (Figure 6A) compared with rapid

increase in the bag with reduction after medium

addition (Figure 6B). Transduction efficiency in the

G-Rex 100MCS was 55 § 7%, compared with 73 §

7% in the RetroNectin-coated bag process

(Figure 6C). Significantly more total viable cells (2.8

§ 0.4 £ 10

9

vs 4.2 § 1.0 £ 10

8

) and transgenic cells

(1.4 § 0.1 £ 10

9

vs 3.2 § 0.9 £ 10

8

) were harvested

from the G-Rex compared with the bag process

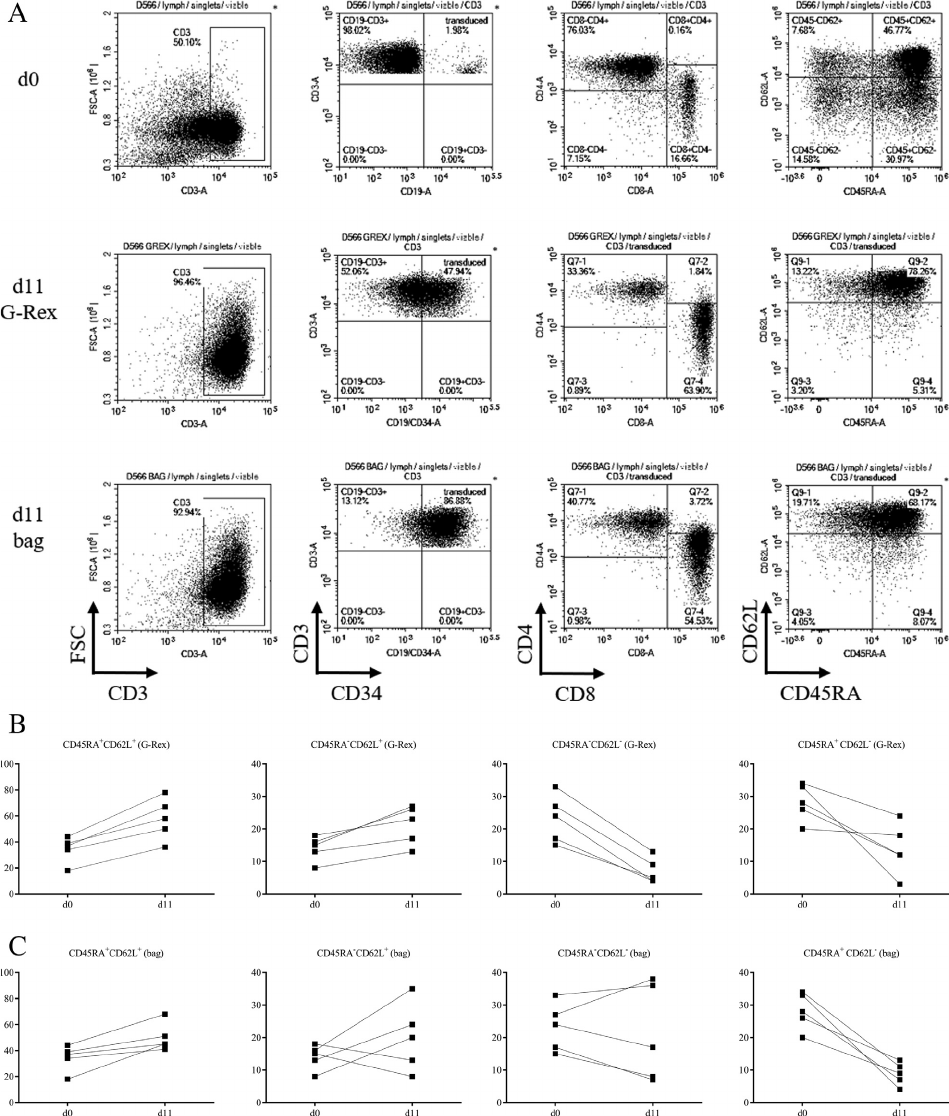

(Figure 6E and 6F). There was no difference in the

distribution of CD45RA and CD62L cell expression

or CD4:CD8 ratio between cells generated in the

two processes (Figure 7). Incubation of the G-

Rexcultured cells, transduced with a PSCA CAR

with inducible co-stimulation, on PSCA

+

target cells

resulted in a functional response measured by secre-

tion of cytokines (Figure 8) that did not differ from

that of cells produced in the conventional process.

The cost of reagents and consumables to generate

equivalent batch sizes from each process was esti-

mated based on currently available list prices

Figure 6. Large-scale G-Rex process compared with bag process lactate, transduction and expansion. (A, B) Lactate concentration (y-axis)

plotted against process day (x-axis) for large-scale G-Rex100MCS (A) and bag cultures (B). (CF) Comparison of transduction percentage

(A), fold change (B), total cells at harvest (C) and total transduced cells at harvest (D) of cells generated in the G-Rex and bag-based pro-

cesses. Each marker represents 1 donor. ***P 0.001, not significant P > 0.05.

1252 C. Gagliardi et al.

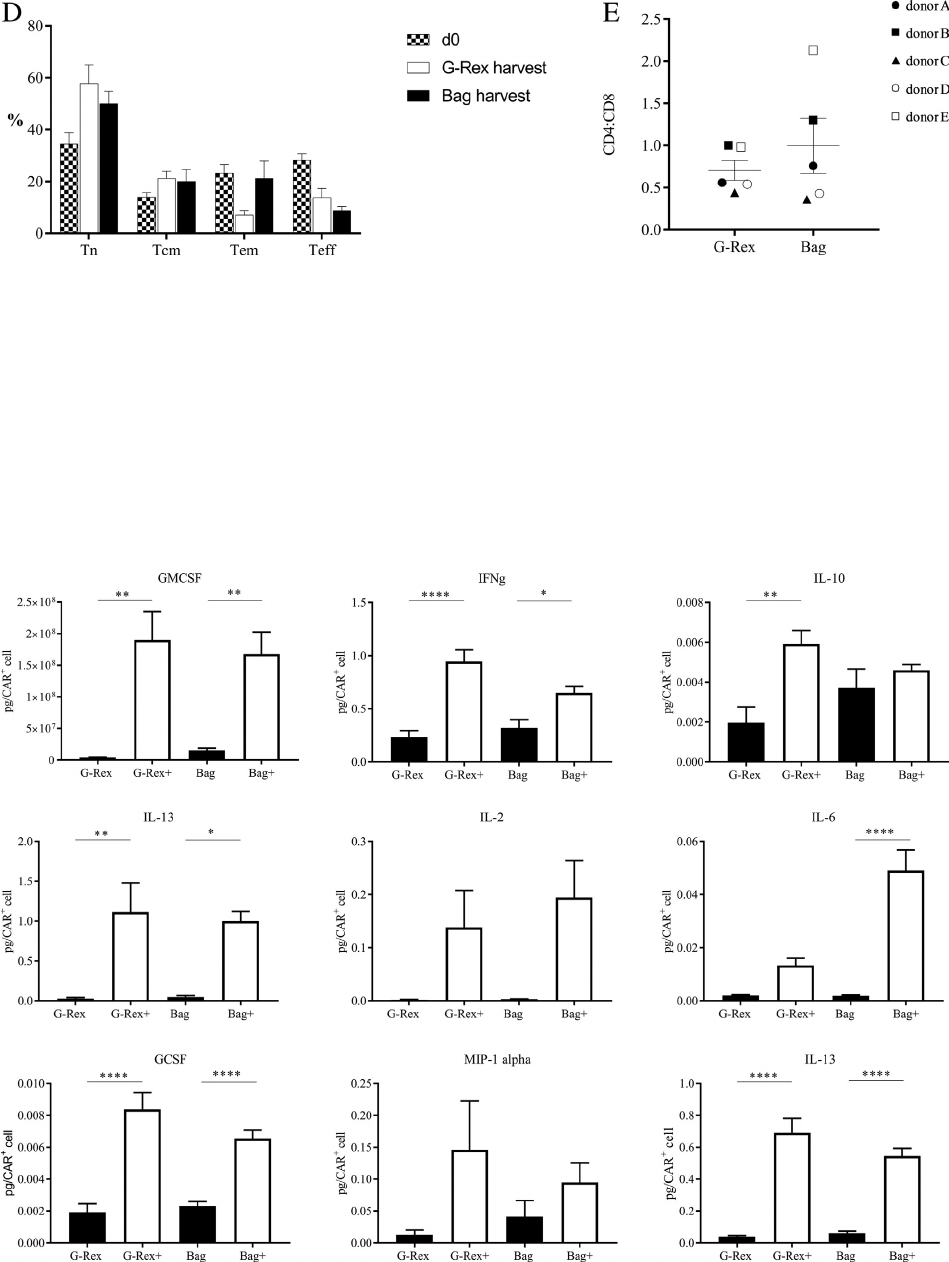

Figure 7. Phenotype of cells generated in the G-Rex and bag process is not different. (A) Sample flow plots for one donor on the initial day

of the process (d0), and after harvest from the G-Rex and bag. The transgene is detected using a CD34 marker. (B, C) Distribution of

CD45RA and CD62L expression on d0 and d11 for the G-Rex (B) and bag (C) processes. (D) Percentage of CD45RA

+

CD62L

+

(Tn),

CD45RA

CD62l

+

(Tcm), CD45RA

CD62L

(Teff) and CD45RA

CD62L

(Tem) from day 0 (checkered bar), G-Rex harvest (white

bar) and bag harvest (black bar). Two-tailed, unpaired t-test was used to compare G-Rex harvest to bag harvest, with no significant differ-

ence between the 2 for any population. (E) CD4:CD8 ratio at harvest from G-Rex or bags.

Streamline production of genetically modified T cells 1253

(Table 1). According to these calculations, materials

for the newly developed process would cost approxi-

mately 38% less than that for a conventional process.

Most of the cost reduction is due to the efficiency of

cell expansion in the G-Rex, which reduces the start-

ing cell number by 4-fold. A comparison between the

time required per operation for each process was also

made (Table 2), demonstrating a significant reduc-

tion of hands-on time for the G-Rexbased process.

Discussion

A major obstacle to manufacturing engineered

T cells is introduction of transge nes such as

CARs. Here we d emonstrate a simple method for

transducing T cells in suspens ion and show inte-

gration of the novel transduction s tep into a

streamlined manufacturing process that relies on a

single G-Rex bioreactor throughout. Al though

Figure 7 Continued.

Figure 8. Similar function of transgene in cells generated in the G-Rex and bag processes. Cytokine secretion, normalized to pg/CAR

+

cell,

of CAR T cells produced in the G-Rex and bag large-scale process after incubation with target cells § drug to provide co-stimulation. Black

bars represent conditions without drug; white bars represent conditions with drug. *P 0.05, **P 0.01, ***P 0.001, ****P 0.0001.

1254 C. Gagliardi et al.

functionally closed and efficient for expanding

cells [315], the G-Rex bioreactors have not, to

date, addressed the practical challenges of genetic

modification of T cells. The first goal of this study

was, the refore, to develop a transduction protocol

that would work for transducing T cells in suspen-

sion in the G-Rex.

Transduction of T cells has typically relied upon

RetroNectin-coated cell culture bags or plates. Given

that RetroNectin coating of the silicone membrane is

not possible, Vectofusin-1 reagent, which is added in

solution, was tested as an alternative for transduction

in the G-Rex. Incubation of retrovirus with activated

T cells in low volumes to increase cell/virus interac-

tion, but without transduction-enhancing reagents,

resulted in transduction efficiency of <1%. Adding

Vectofusin-1 increased transduction efficiency to

825% at MOI 1. Transduction efficiency was

increased with increasing MOI, and that increase

reached a maximum at MOI 10 (>80%). Medium

addition after transduction, without washing,

allowed for expansion of the transduced T cells in

the G-Rex, although expansion tended to be nega-

tively impacted at MOI 10.

Transduction and expansion of cells in the G-Rex

eliminate the complexity of transduction with Retro-

Nectin, but still require initial activation, with a wash

and transfer step. To further simplify the process,

activation in the G-Rex prior to transduction was

also evaluated. PBMCs activated in the G-Rex in 0.4

Table 1. Bag and G-Rex process cost comparison.

Bag-based process G-Rexbased process

Item Manufacturer Catalog no. Size List price Required

per run

Cost

per run

Required

per run

Cost

per run

TexMACS GMP

medium

Miltenyi Biotec 170-075-306 2 L $ 305.00 1.00 $ 305.00 1.00 $ 305.00

MACS GMP

Vectofusin-1

Miltenyi Biotec 170-076-165 1 mg $ 875.00 0.00 $ - 1.00 $ 875.00

G-Rex 100MCS Wilson Wolf Corp 81100-CS 3 pack $ 729.84 0.00 $ - 0.33 $ 243.28

MACS GMP CD3

pure

Miltenyi Biotec 170-076-116 1 mg $ 1750.00 0.58 $ 1015.00 0.08 $ 140.00

MACS GMP CD28

pure

Miltenyi Biotec 170-076-117 0.5 mg $ 895.00 1.45 $ 1297.75 0.20 $ 179.00

hIL-7, premium

grade

Miltenyi Biotec 130-095-363 100 mg $ 1150.00 0.13 $ 149.50 0.45 $ 517.50

hIL-15, premium

grade

Miltenyi Biotec 130-095-765 100 mg $ 1150.00 0.04 $ 46.00 0.15 $ 172.50

Retronectin, GMP

grade

Takara T202 2.5 mL $ 1442.00 0.50 $ 721.00 0.00 $ -

Cell culture bags Saint Gobain 290-C 10 pack $ 993.51 0.30 $ 298.05 0.00 $ -

Transduction bag Saint Gobain 290-AC 10 pack $ 993.51 0.10 $ 99.35 0.00 $ -

$3931.65 $2432.28

The cost of generating 1.4 £ 10

9

transduced cells in the bag- and G-Rexbased process. Cost for the bag process was calculated based on

scaling up to a process that could generate as many cells as the G-Rexbased process.

Table 2. Bag and G-Rex process time comparison.

Operation Bag-based process G-Rex-based process

Method Time (h) Method Time (h)

Activation Anti-CD3/CD28 in solution 1.00 Anti-CD3/CD28 in solution 1.00

Transduction Culture wash, transfer to

Retronectin-coated bags

4.00 Vectofusin-1 in solution 0.50

Transduction stop Culture wash, transfer bag 2.00 Medium addition 0.50

Expansion Feed and transfer, as needed 4.00 NA 0.00

Harvest Centrifuge 2.00 GatheRex 0.50

In-process monitoring Mix cell suspension, sample

for count (x6 d)

3.00 Sample supernatant for lactate (x6 d) 1.50

16.00 4.00

The estimated time, in hours, required for each operation in the bag- and G-Rexbased process. Estimates are based on a single operator

working in a non-GMP setting.

NA, not applicable.

Streamline production of genetically modified T cells 1255

mL/cm

2

were transduced with 15% efficiency. This

is slightly lower than cells activated in bags, but also

significantly reduces operator time and eliminates

wash and transfer of cells between activation and

transduction, reducing risk of contamination or other

errors.

These data demonstrate that the transduction step

can be streamlined to simple addition of reagents to

cells rather than RetroNectin coating, washing and

transferring cells pre- and post-transduction. This

method has the potential to reduce clean room time,

operator input and risk of contamination.

Using data from the small-scale experiments,

suggesting an optimal seeding density of

0.51.0 £ 10

6

cells/cm

2

andanactivationvolume

of 0.4 mL/cm

2

, a GMP-compatible process was

devised. Prioritizin g simpl icity over other parame-

ters, PBMCs were activated, transduced and

expanded in a single G-Rex bioreactor. Five runs

each of the simplified G-Rexbased process and

the standard bag process were performed in parallel.

There was no differen ce in phenotype or funct ion of

the cells generated in the two processe s. There was

a trend toward higher transduc tion in the bag,

although that difference was not statistically signifi-

cant. Expansion i n the G-Rex bioreactor resulted in

significantly more total vi able cells and transgenic

cells at harvest. The average harvest from the G-

Rex process was 1.4 § 0.1 £ 10

9

transgenic cells. A

hypothetical 80-kg patient who needs a dose of

5.0 £ 10

6

cells/kg could receive >3 doses from one

manufacturing process with the G-Rex. In compari-

son, a bag process, starting with t he same number

of cells, results in barely enough transgenic cells for

a single dose of the same size. Further, the G-

Rexbased process reduced the cost of mate rials by

38% and hand-on time by 75% to generate a batch

of 1.4 £ 10

9

transgenic cells.

This study demonstrates that T cells can be trans-

duced with retroviral vectors in solution in the G-Rex

bioreactor with addition of Vectofusin-1 as a trans-

duction enhancer. The simplified transduction step

allow for an entire process, from activation to har-

vest, to be carried out in a single vessel. Clinically rel-

evant levels of transgene expression and cell numbers

can be achieved by combining reagents in the G-

Rex, without complicated time-consuming coating

steps of traditional transduction.

The streamlined procedure reduces the hands-on

time of transduction to minutes rather than hours

and eliminates all cell transfer and wash steps. Fur-

ther, the increased output per starting material

reduces cost of materials compared with the standard

method. Cells can be expanded in the G-Rex with

limited operator intervention and without specialized

equipment.

Declaration of Competing Interest

All authors are employees of Bellicum Pharmaceuti-

cals. This research did not receive any specific grant

from funding agencies in the public, commercial or

not-for-profit sectors.

Author Contributions

Conception and design of the study: CG. Acquisition

of data: MK, CG. Analysis and interpretation of data:

MK, CG. Drafting or revising the manuscript: MK,

CG, AEF. All authors have approved the final article.

References

[1] Fenard D, Ingrao D, Seye A, Buisset J, Genries S, Martin S,

et al. Vectofusin-1, a new viral entry enhancer, strongly pro-

motes lentiviral transduction of human hematopoietic stem

cells. Mol Ther Nucleic Acids 2013;2:e90.

[2] Vermeer LS, Hamon L, Schirer A, Schoup M, Cosette J,

Majdoul S, et al. Vectofusin-1, a potent peptidic enhancer of

viral gene transfer forms pH-dependent alpha-helical nanofi-

brils, concentrating viral particles. Acta Biomater 2017;

64:259–68.

[3] Vera JF, Brenner LJ, Gerdemann U, Ngo MC, Sili U, Liu H,

et al. Accelerated production of antigen-specific T cells for

preclinical and clinical applications using gas-permeable

rapid expansion cultureware (G-Rex). J Immunother 2010;

33(3):305–15.

[4] Bajgain P, Mucharla R, Wilson J, Welch D, Anurathapan U,

Liang B, et al. Optimizing the production of suspension cells

using the G-Rex “M” series. Mol Ther Methods Clin Dev

2014;1:14015.

[5] Forget MA, Haymaker C, Dennison JB, Toth C, Maiti S,

Fulbright OJ, et al. The beneficial effects of a gas-permeable

flask for expansion of tumor-infiltrating lymphocytes as

reflected in their mitochondrial function and respiration

capacity. Oncoimmunology 2016;5(2):e1057386.

[6] Jin J, Sabatino M, Somerville R, Wilson JR, Dudley ME,

Stroncek DF, et al. Simplified method of the growth of

human tumor infiltrating lymphocytes in gas-permeable

flasks to numbers needed for patient treatment. J Immun-

other 2012;35(3):283–92.

[7] Lapteva N, Durett AG, Sun J, Rollins LA, Huye LL, Fang J,

et al. Large-scale ex vivo expansion and characterization of

natural killer cells for clinical applications. Cytotherapy

2012;14(9):1131–43.

[8] Lapteva N, Szmania SM, van Rhee F, Rooney CM. Clinical

grade purification and expansion of natural killer cells. Crit

Rev Oncog 2014;19(1-2):121–32.

[9] Lapteva N, Parihar R, Rollins LA, Gee AP, Rooney CM.

Large-scale culture and genetic modification of human natu-

ral killer cells for cellular therapy. Methods Mol Biol 2016;

1441:195–202.

[10] Xiao L, Chen C, Li Z, Zhu S, Tay JC, Zhang X, et al. Large-

scale expansion of Vgamma9Vdelta2 T cells with engineered

K562 feeder cells in G-Rex vessels and their use as chimeric

antigen receptor-modified effector cells. Cytotherapy 2018;

20(3):420–35.

[11] Chakraborty R, Mahendravada A, Perna SK, Rooney CM,

Heslop HE, Vera JF, et al. Robust and cost effective expan-

sion of human regulatory T cells highly functional in a

1256 C. Gagliardi et al.

xenograft model of graft-versus-host disease. Haematologica

2013;98(4):533–7.

[12] Gerdemann U, Katari UL, Papadopoulou A, Keirnan JM,

Craddock JA, Liu H, et al. Safety and clinical efficacy of rapidly-

generated trivirus-directed T cells as treatment for adenovirus,

EBV, and CMV infections after allogeneic hematopoietic stem

cell transplant. Mol Ther 2013;21(11):2113–21.

[13] Horlock C, Skulte A, Mitra A, Stansfield A, Bhandari S, Ip

W, et al. Manufacture of GMP-compliant functional adeno-

virus-specific T-cell therapy for treatment of post-transplant

infectious complications. Cytotherapy 2016;18(9):1209–18.

[14] Gerdemann U, Vera JF, Rooney CM, Leen AM. Generation

of multivirus-specific T cells to prevent/treat viral infections

after allogeneic hematopoietic stem cell transplant. J Vis Exp

2011(51):2736.

[15] Lapteva N, Vera JF. Optimization manufacture of virus- and

tumor-specific T cells. Stem Cells Int 2011(2011):434392.

[16] Duong MT, Collinson-Pautz MR, Morschl E, Lu A, Szy-

manski SP, Zhang M, et al. Two-dimensional regulation of

CAR-T cell therapy with orthogonal switches. Mol Ther

Oncolytics 2019;12:124–37.

[17] Philip B, Kokalaki E, Mekkaoui L, Thomas S, Straathof K,

Flutter B, et al. A highly compact epitope-based marker/sui-

cide gene for easier and safer T-cell therapy. Blood 2014;124

(8):1277–87.

[18] Foster AE, Mahendravada A, Shinners NP, Chang WC, Cri-

sostomo J, Lu A, et al. Regulated expansion and survival of

chimeric antigen receptor-modified T cells using small mole-

cule-dependent inducible MyD88/CD40. Mol Ther 2017;25

(9):2176–88.

[19] Narayanan P, Lapteva N, Seethammagari M, Levitt JM, Slawin

KM, Spencer DM. A composite MyD88/CD40 switch synergis-

tically activates mouse and human dendritic cells for enhanced

antitumor efficacy. J Clin Invest 2011;121(4):1524–34.

Streamline production of genetically modified T cells 1257